INFP - INFINITY Process Panel Meter DC Current ... - NEWPORT

INFP - INFINITY Process Panel Meter DC Current ... - NEWPORT

INFP - INFINITY Process Panel Meter DC Current ... - NEWPORT

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

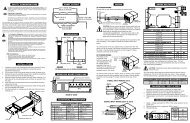

Scaling to Display Engineering Units 88.3 SCALING YOUR METER USING 2-COORDINATE INPUT SCALE ANDOFFSET (IN.SC.OF) WITH SENSOR CONNECTED TO YOUR METERThe most accurate method for scaling your meter to display engineeringunits is by connecting your sensor to your meter, apply two known loads,record them as INPUT1 and INPUT2 respectively and use these numbersfor entry into 2-coordinate Input Scale and Offset (“IN.SC.OF”).The typical factory calibration and configuration is for the meter to accept a4-20 mA dc and scaled to display 0 to 020000.An example would be a 2-wire transmitter that sends a signal of 4-20 mAdc.With a signal input of 4 mA the display will show “000000” and with a signalinput of 20 mA this display will show “02000”. However, the output signalfrom your transmitter may be something like 3.98 mA and 19.99 mA. UsingInput Scale and Offset (“IN.SC.OF”) you can configure your meter toaccurately display your required engineering units.Note ☞NOTE: Although the full span input of your sensor signal is preferred formaximum resolution, you may record any two points within the signal spanfor scaling accurately into engineering units.The following will walk you step by step in configuring your meter for scalingyour meter using the Input Scale and Offset (“IN.SC.OF”) procedure.37