federal register - U.S. Government Printing Office

federal register - U.S. Government Printing Office

federal register - U.S. Government Printing Office

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

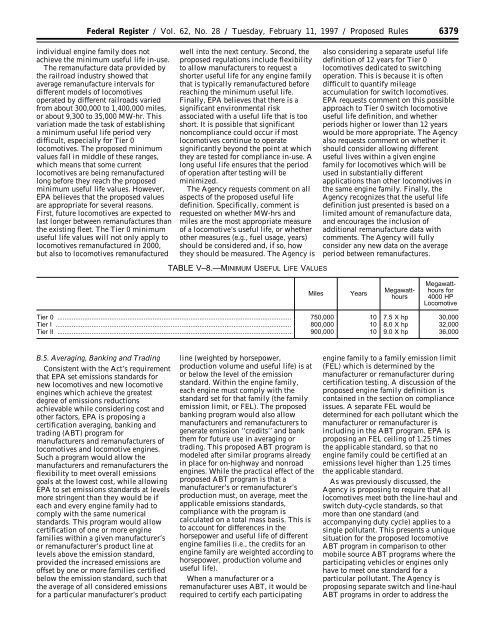

Federal Register / Vol. 62, No. 28 / Tuesday, February 11, 1997 / Proposed Rules6379individual engine family does notachieve the minimum useful life in-use.The remanufacture data provided bythe railroad industry showed thataverage remanufacture intervals fordifferent models of locomotivesoperated by different railroads variedfrom about 300,000 to 1,400,000 miles,or about 9,300 to 35,000 MW-hr. Thisvariation made the task of establishinga minimum useful life period verydifficult, especially for Tier 0locomotives. The proposed minimumvalues fall in middle of these ranges,which means that some currentlocomotives are being remanufacturedlong before they reach the proposedminimum useful life values. However,EPA believes that the proposed valuesare appropriate for several reasons.First, future locomotives are expected tolast longer between remanufactures thanthe existing fleet. The Tier 0 minimumuseful life values will not only apply tolocomotives remanufactured in 2000,but also to locomotives remanufacturedwell into the next century. Second, theproposed regulations include flexibilityto allow manufacturers to request ashorter useful life for any engine familythat is typically remanufactured beforereaching the minimum useful life.Finally, EPA believes that there is asignificant environmental riskassociated with a useful life that is tooshort. It is possible that significantnoncompliance could occur if mostlocomotives continue to operatesignificantly beyond the point at whichthey are tested for compliance in-use. Along useful life ensures that the periodof operation after testing will beminimized.The Agency requests comment on allaspects of the proposed useful lifedefinition. Specifically, comment isrequested on whether MW-hrs andmiles are the most appropriate measureof a locomotive’s useful life, or whetherother measures (e.g., fuel usage, years)should be considered and, if so, howthey should be measured. The Agency isalso considering a separate useful lifedefinition of 12 years for Tier 0locomotives dedicated to switchingoperation. This is because it is oftendifficult to quantify mileageaccumulation for switch locomotives.EPA requests comment on this possibleapproach to Tier 0 switch locomotiveuseful life definition, and whetherperiods higher or lower than 12 yearswould be more appropriate. The Agencyalso requests comment on whether itshould consider allowing differentuseful lives within a given enginefamily for locomotives which will beused in substantially differentapplications than other locomotives inthe same engine family. Finally, theAgency recognizes that the useful lifedefinition just presented is based on alimited amount of remanufacture data,and encourages the inclusion ofadditional remanufacture data withcomments. The Agency will fullyconsider any new data on the averageperiod between remanufactures.TABLE V–8.—MINIMUM USEFUL LIFE VALUESMilesYearsMegawatthoursMegawatthoursfor4000 HPLocomotiveTier 0 .................................................................................................................................. 750,000 10 7.5 X hp 30,000Tier I ................................................................................................................................... 800,000 10 8.0 X hp 32,000Tier II .................................................................................................................................. 900,000 10 9.0 X hp 36,000B.5. Averaging, Banking and TradingConsistent with the Act’s requirementthat EPA set emissions standards fornew locomotives and new locomotiveengines which achieve the greatestdegree of emissions reductionsachievable while considering cost andother factors, EPA is proposing acertification averaging, banking andtrading (ABT) program formanufacturers and remanufacturers oflocomotives and locomotive engines.Such a program would allow themanufacturers and remanufacturers theflexibility to meet overall emissionsgoals at the lowest cost, while allowingEPA to set emissions standards at levelsmore stringent than they would be ifeach and every engine family had tocomply with the same numericalstandards. This program would allowcertification of one or more enginefamilies within a given manufacturer’sor remanufacturer’s product line atlevels above the emission standard,provided the increased emissions areoffset by one or more families certifiedbelow the emission standard, such thatthe average of all considered emissionsfor a particular manufacturer’s productline (weighted by horsepower,production volume and useful life) is ator below the level of the emissionstandard. Within the engine family,each engine must comply with thestandard set for that family (the familyemission limit, or FEL). The proposedbanking program would also allowmanufacturers and remanufacturers togenerate emission ‘‘credits’’ and bankthem for future use in averaging ortrading. This proposed ABT program ismodeled after similar programs alreadyin place for on-highway and nonroadengines. While the practical effect of theproposed ABT program is that amanufacturer’s or remanufacturer’sproduction must, on average, meet theapplicable emissions standards,compliance with the program iscalculated on a total mass basis. This isto account for differences in thehorsepower and useful life of differentengine families (i.e., the credits for anengine family are weighted according tohorsepower, production volume anduseful life).When a manufacturer or aremanufacturer uses ABT, it would berequired to certify each participatingengine family to a family emission limit(FEL) which is determined by themanufacturer or remanufacturer duringcertification testing. A discussion of theproposed engine family definition iscontained in the section on complianceissues. A separate FEL would bedetermined for each pollutant which themanufacturer or remanufacturer isincluding in the ABT program. EPA isproposing an FEL ceiling of 1.25 timesthe applicable standard, so that noengine family could be certified at anemissions level higher than 1.25 timesthe applicable standard.As was previously discussed, theAgency is proposing to require that alllocomotives meet both the line-haul andswitch duty-cycle standards, so thatmore than one standard (andaccompanying duty cycle) applies to asingle pollutant. This presents a uniquesituation for the proposed locomotiveABT program in comparison to othermobile source ABT programs where theparticipating vehicles or engines onlyhave to meet one standard for aparticular pollutant. The Agency isproposing separate switch and line-haulABT programs in order to address the