federal register - U.S. Government Printing Office

federal register - U.S. Government Printing Office

federal register - U.S. Government Printing Office

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

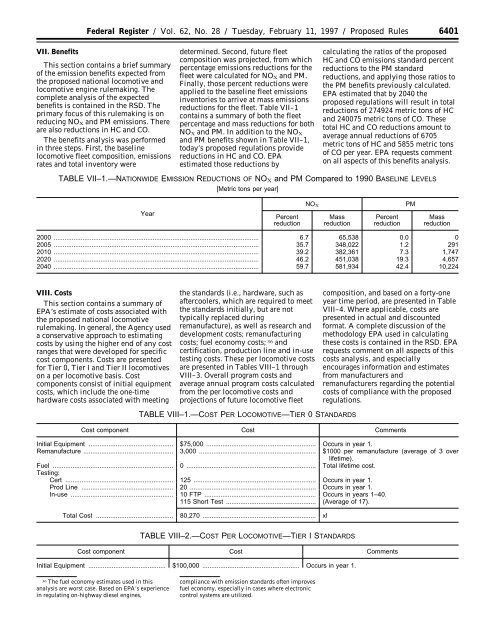

Federal Register / Vol. 62, No. 28 / Tuesday, February 11, 1997 / Proposed Rules6401VII. BenefitsThis section contains a brief summaryof the emission benefits expected fromthe proposed national locomotive andlocomotive engine rulemaking. Thecomplete analysis of the expectedbenefits is contained in the RSD. Theprimary focus of this rulemaking is onreducing NO X and PM emissions. Thereare also reductions in HC and CO.The benefits analysis was performedin three steps. First, the baselinelocomotive fleet composition, emissionsrates and total inventory weredetermined. Second, future fleetcomposition was projected, from whichpercentage emissions reductions for thefleet were calculated for NO X and PM.Finally, those percent reductions wereapplied to the baseline fleet emissionsinventories to arrive at mass emissionsreductions for the fleet. Table VII–1contains a summary of both the fleetpercentage and mass reductions for bothNO X and PM. In addition to the NO Xand PM benefits shown in Table VII–1,today’s proposed regulations providereductions in HC and CO. EPAestimated those reductions bycalculating the ratios of the proposedHC and CO emissions standard percentreductions to the PM standardreductions, and applying those ratios tothe PM benefits previously calculated.EPA estimated that by 2040 theproposed regulations will result in totalreductions of 274924 metric tons of HCand 240075 metric tons of CO. Thesetotal HC and CO reductions amount toaverage annual reductions of 6705metric tons of HC and 5855 metric tonsof CO per year. EPA requests commenton all aspects of this benefits analysis.TABLE VII–1.—NATIONWIDE EMISSION REDUCTIONS OF NO X and PM Compared to 1990 BASELINE LEVELS[Metric tons per year]NO XPMYearPercentreductionMassreductionPercentreductionMassreduction2000 .................................................................................................................. 6.7 65,538 0.0 02005 .................................................................................................................. 35.7 348,022 1.2 2912010 .................................................................................................................. 39.2 382,361 7.3 1,7472020 .................................................................................................................. 46.2 451,038 19.3 4,6572040 .................................................................................................................. 59.7 581,934 42.4 10,224VIII. CostsThis section contains a summary ofEPA’s estimate of costs associated withthe proposed national locomotiverulemaking. In general, the Agency useda conservative approach to estimatingcosts by using the higher end of any costranges that were developed for specificcost components. Costs are presentedfor Tier 0, Tier I and Tier II locomotiveson a per locomotive basis. Costcomponents consist of initial equipmentcosts, which include the one-timehardware costs associated with meetingthe standards (i.e., hardware, such asaftercoolers, which are required to meetthe standards initially, but are nottypically replaced duringremanufacture), as well as research anddevelopment costs; remanufacturingcosts; fuel economy costs; 36 andcertification, production line and in-usetesting costs. These per locomotive costsare presented in Tables VIII–1 throughVIII–3. Overall program costs andaverage annual program costs calculatedfrom the per locomotive costs andprojections of future locomotive fleetcomposition, and based on a forty-oneyear time period, are presented in TableVIII–4. Where applicable, costs arepresented in actual and discountedformat. A complete discussion of themethodology EPA used in calculatingthese costs is contained in the RSD. EPArequests comment on all aspects of thiscosts analysis, and especiallyencourages information and estimatesfrom manufacturers andremanufacturers regarding the potentialcosts of compliance with the proposedregulations.TABLE VIII–1.—COST PER LOCOMOTIVE—TIER 0 STANDARDSCost component Cost CommentsInitial Equipment ............................................... $75,000 ............................................................. Occurs in year 1.Remanufacture .................................................. 3,000 ................................................................. $1000 per remanufacture (average of 3 overlifetime).Fuel ................................................................... 0 ........................................................................ Total lifetime cost.Testing:Cert ............................................................ 125 .................................................................... Occurs in year 1.Prod Line ................................................... 20 ...................................................................... Occurs in year 1.In-use ......................................................... 10 FTP .............................................................. Occurs in years 1–40.115 Short Test .................................................. (Average of 17).Total Cost ........................................... 80,270 ............................................................... xlTABLE VIII–2.—COST PER LOCOMOTIVE—TIER I STANDARDSCost component Cost CommentsInitial Equipment ........................................... $100,000 ...................................................... Occurs in year 1.36 The fuel economy estimates used in thisanalysis are worst case. Based on EPA’s experiencein regulating on-highway diesel engines,compliance with emission standards often improvesfuel economy, especially in cases where electroniccontrol systems are utilized.