federal register - U.S. Government Printing Office

federal register - U.S. Government Printing Office

federal register - U.S. Government Printing Office

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

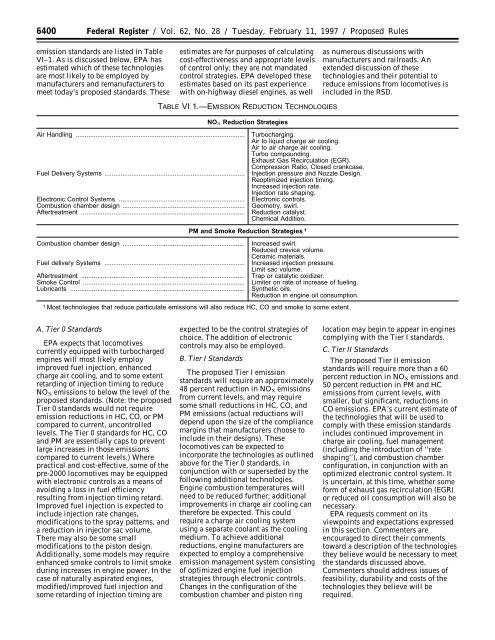

6400 Federal Register / Vol. 62, No. 28 / Tuesday, February 11, 1997 / Proposed Rulesemission standards are listed in TableVI–1. As is discussed below, EPA hasestimated which of these technologiesare most likely to be employed bymanufacturers and remanufacturers tomeet today’s proposed standards. Theseestimates are for purposes of calculatingcost-effectiveness and appropriate levelsof control only; they are not mandatedcontrol strategies. EPA developed theseestimates based on its past experiencewith on-highway diesel engines, as wellas numerous discussions withmanufacturers and railroads. Anextended discussion of thesetechnologies and their potential toreduce emissions from locomotives isincluded in the RSD.TABLE VI 1.—EMISSION REDUCTION TECHNOLOGIESNO X Reduction StrategiesAir Handling ..............................................................................................Fuel Delivery Systems ..............................................................................Electronic Control Systems ......................................................................Combustion chamber design ....................................................................Aftertreatment ...........................................................................................Turbocharging.Air to liquid charge air cooling.Air to air charge air cooling.Turbo compounding.Exhaust Gas Recirculation (EGR).Compression Ratio, Closed crankcase.Injection pressure and Nozzle Design.Reoptimized injection timing.Increased injection rate.Injection rate shaping.Electronic controls.Geometry, swirl.Reduction catalyst.Chemical Addition.Combustion chamber design ....................................................................Fuel delivery Systems ..............................................................................Aftertreatment ...........................................................................................Smoke Control ..........................................................................................Lubricants .................................................................................................PM and Smoke Reduction Strategies 1Increased swirl.Reduced crevice volume.Ceramic materials.Increased injection pressure.Limit sac volume.Trap or catalytic oxidizer.Limiter on rate of increase of fueling.Synthetic oils.Reduction in engine oil consumption.1 Most technologies that reduce particulate emissions will also reduce HC, CO and smoke to some extent.A. Tier 0 StandardsEPA expects that locomotivescurrently equipped with turbochargedengines will most likely employimproved fuel injection, enhancedcharge air cooling, and to some extentretarding of injection timing to reduceNO X emissions to below the level of theproposed standards. (Note: the proposedTier 0 standards would not requireemission reductions in HC, CO, or PMcompared to current, uncontrolledlevels. The Tier 0 standards for HC, COand PM are essentially caps to preventlarge increases in those emissionscompared to current levels.) Wherepractical and cost-effective, some of thepre-2000 locomotives may be equippedwith electronic controls as a means ofavoiding a loss in fuel efficiencyresulting from injection timing retard.Improved fuel injection is expected toinclude injection rate changes,modifications to the spray patterns, anda reduction in injector sac volume.There may also be some smallmodifications to the piston design.Additionally, some models may requireenhanced smoke controls to limit smokeduring increases in engine power. In thecase of naturally aspirated engines,modified/improved fuel injection andsome retarding of injection timing areexpected to be the control strategies ofchoice. The addition of electroniccontrols may also be employed.B. Tier I StandardsThe proposed Tier I emissionstandards will require an approximately48 percent reduction in NO X emissionsfrom current levels, and may requiresome small reductions in HC, CO, andPM emissions (actual reductions willdepend upon the size of the compliancemargins that manufacturers choose toinclude in their designs). Theselocomotives can be expected toincorporate the technologies as outlinedabove for the Tier 0 standards, inconjunction with or superseded by thefollowing additional technologies.Engine combustion temperatures willneed to be reduced further; additionalimprovements in charge air cooling cantherefore be expected. This couldrequire a charge air cooling systemusing a separate coolant as the coolingmedium. To achieve additionalreductions, engine manufacturers areexpected to employ a comprehensiveemission management system consistingof optimized engine fuel injectionstrategies through electronic controls.Changes in the configuration of thecombustion chamber and piston ringlocation may begin to appear in enginescomplying with the Tier I standards.C. Tier II StandardsThe proposed Tier II emissionstandards will require more than a 60percent reduction in NO X emissions and50 percent reduction in PM and HCemissions from current levels, withsmaller, but significant, reductions inCO emissions. EPA’s current estimate ofthe technologies that will be used tocomply with these emission standardsincludes continued improvement incharge air cooling, fuel management(including the introduction of ‘‘rateshaping’’), and combustion chamberconfiguration, in conjunction with anoptimized electronic control system. Itis uncertain, at this time, whether someform of exhaust gas recirculation (EGR)or reduced oil consumption will also benecessary.EPA requests comment on itsviewpoints and expectations expressedin this section. Commenters areencouraged to direct their commentstoward a description of the technologiesthey believe would be necessary to meetthe standards discussed above.Commenters should address issues offeasibility, durability and costs of thetechnologies they believe will berequired.