Installatiefiche - Delta-Temp

Installatiefiche - Delta-Temp

Installatiefiche - Delta-Temp

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

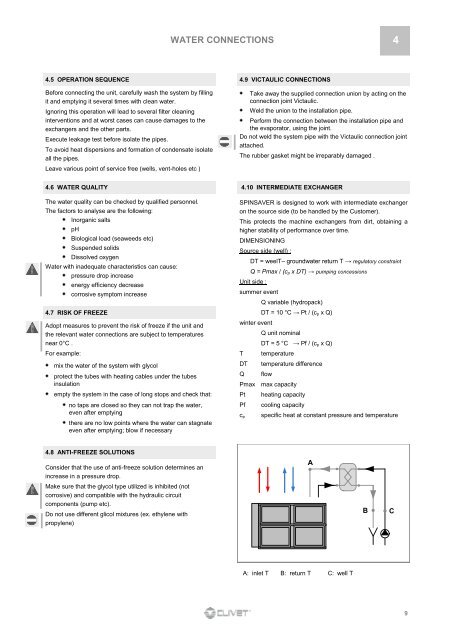

WATER CONNECTIONS44.5 OPERATION SEQUENCEBefore connecting the unit, carefully wash the system by fillingit and emptying it several times with clean water.Ignoring this operation will lead to several filter cleaninginterventions and at worst cases can cause damages to theexchangers and the other parts.Execute leakage test before isolate the pipes.To avoid heat dispersions and formation of condensate isolateall the pipes.Leave various point of service free (wells, vent-holes etc )4.9 VICTAULIC CONNECTIONSTake away the supplied connection union by acting on theconnection joint Victaulic.Weld the union to the installation pipe.Perform the connection between the installation pipe andthe evaporator, using the joint.Do not weld the system pipe with the Victaulic connection jointattached.The rubber gasket might be irreparably damaged .4.6 WATER QUALITYThe water quality can be checked by qualified personnel.The factors to analyse are the following:Adopt measures to prevent the risk of freeze if the unit andthe relevant water connections are subject to temperaturesnear 0°C .For example:Inorganic saltspHBiological load (seaweeds etc)Suspended solidsDissolved oxygenWater with inadequate characteristics can cause:pressure drop increaseenergy efficiency decreasecorrosive symptom increase4.7 RISK OF FREEZEmix the water of the system with glycolprotect the tubes with heating cables under the tubesinsulationempty the system in the case of long stops and check that:no taps are closed so they can not trap the water,even after emptyingthere are no low points where the water can stagnateeven after emptying; blow if necessary4.10 INTERMEDIATE EXCHANGERSPINSAVER is designed to work with intermediate exchangeron the source side (to be handled by the Customer).This protects the machine exchangers from dirt, obtaining ahigher stability of performance over time.DIMENSIONINGSource side (well) :DT = weelT– groundwater return T → regulatory constraintQ = Pmax / (c p x DT) → pumping concessionsUnit side :summer eventwinter eventTDTQQ variable (hydropack)DT = 10 °C → Pt / (c p x Q)Q unit nominalDT = 5 °C → Pf / (c p x Q)temperaturetemperature differenceflowPmax max capacityPtPfc pheating capacitycooling capacityspecific heat at constant pressure and temperature4.8 ANTI-FREEZE SOLUTIONSConsider that the use of anti-freeze solution determines anincrease in a pressure drop.Make sure that the glycol type utilized is inhibited (notcorrosive) and compatible with the hydraulic circuitcomponents (pump etc).Do not use different glicol mixtures (ex. ethylene withpropylene)ABCA: inlet T B: return T C: well T9