Technische fiche - Delta-Temp

Technische fiche - Delta-Temp

Technische fiche - Delta-Temp

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

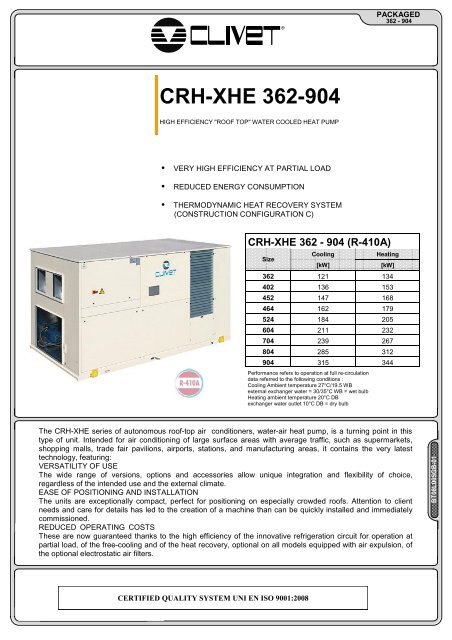

®PACKAGED362 - 904CRH-XHE 362-904HIGH EFFICIENCY "ROOF TOP" WATER COOLED HEAT PUMP• VERY HIGH EFFICIENCY AT PARTIAL LOAD• REDUCED ENERGY CONSUMPTION• THERMODYNAMIC HEAT RECOVERY SYSTEM(CONSTRUCTION CONFIGURATION C)CRH-XHE 362 - 904 (R-410A)SizeCooling[kW]Heating[kW]362 121 134402 136 153452 147 168464 162 179524 184 205604 211 232704 239 267804 285 312904 315 344Performance refers to operation at full re-circulationdata referred to the following conditions :Cooling Ambient temperature 27°C/19.5 WBexternal exchanger water = 30/35°C WB = wet bulbHeating ambient temperature 20°C DBexchanger water outlet 10°C DB = dry bulbThe CRH-XHE series of autonomous roof-top air conditioners, water-air heat pump, is a turning point in thistype of unit. Intended for air conditioning of large surface areas with average traffic, such as supermarkets,shopping malls, trade fair pavilions, airports, stations, and manufacturing areas, it contains the very latesttechnology, featuring:VERSATILITY OF USEThe wide range of versions, options and accessories allow unique integration and flexibility of choice,regardless of the intended use and the external climate.EASE OF POSITIONING AND INSTALLATIONThe units are exceptionally compact, perfect for positioning on especially crowded roofs. Attention to clientneeds and care for details has led to the creation of a machine than can be quickly installed and immediatelycommissioned.REDUCED OPERATING COSTSThese are now guaranteed thanks to the high efficiency of the innovative refrigeration circuit for operation atpartial load, of the free-cooling and of the heat recovery, optional on all models equipped with air expulsion, ofthe optional electrostatic air filters.BT08L005GB-01CERTIFIED QUALITY SYSTEM UNI EN ISO 9001:2008

BT08L005GB-01PACKAGED362 - 904GENERAL DESCRIPTIONMAIN FUNCTIONS AND APPLICATIONSThe CRH-XHE autonomous roof-top air conditioners are highefficiencywater-air heat pumps with completely automaticoperation. Based on user settings, the unit provides complete airtreatment through ventilation, filtering, cooling, heating, completeor partial addition of fresh air, possibility to control humidity. Thesemachines are extremely compact and resistant to atmosphericagents, suitable for outdoor installation on a flat roof, on a platformor on the ground. The distribution of treated air (to be handled bythe client) takes place via supply and return ducts and suitabledistribution devices such as air outlets or nozzles. They aretherefore perfect for air conditioning of large-volume rooms withaverage traffic, such as large commercial surfaces, trade fairpavilions, airports, stations, and production areas.APPLICATIONSVERSATILITY OF USEThe wide range of models and the possibility to choose theconstructive configurations make it possible to select the productthat is best suited to the needs of each installation and to integratethe unit into various architectonic contexts. The selection ofaccessories completes the possibility to customize the productaccording to the needs of the client.VERSATILE POSITIONING: ON FLAT ROOF, ONPLATFORM ON GROUNDEXTREME COMPACTNESSThe original layout of the sections that make up the machinesubstantially reduces its footprint, making it easier to position andleaving more space available for parking, additional equipmentrooms or other uses. This also reduces the time required for thepositioning of the ducts on the various sides of the unit, since itsgreat compactness allows its complete rotation (which is verydifficult with traditional units with in-line extension).APPLICATION EXAMPLESREDUCTION OF CONSUMPTION AND OPERATING COSTSThe roof-top units of the XHE series were created with theobjective of always operating at maximum energy savings throughan extremely intelligent and advanced control of power providedonly when it is needed, especially during frequent conditions ofoperation at partial load. The use of the free-cooling device and theadoption of thermodynamic recovery on the expelled air make itpossible to further reduce operating costs. Since ventilationrepresents one of the greatest factors of energy consumption,special attention has been given to the efficiency of the ventilationsystem through careful selection of components and limitations ofinternal pressure drops. The limitation of the emissions of carbondioxide and respect for the environment are guiding thoughts ofClivet which, through the implementation of modern technicalsolutions, pursues the reduction of energy consumption.EASY MAINTENANCEThe entire series is designed with highly reliable industrialcomponents that are easily accessible and available ifmaintenance is required. It is also equipped with self-diagnosis andsafety devices that ensure its proper operation while at the sametime protecting users.2

BT08L005GB-01GENERAL DESCRIPTION OF CONFIGURATIONS AVAILABLE IN CATALOGUEPACKAGED362 - 904The CRH-XHE range of air conditioners is highly customizable and is based on a standard model (version B), ona model with integrated expulsion (version C) and on a model with integrated expulsion and energy recovery onexpelled air (version C with recovery). Both configuration are capable of conditioning air flow rates with mixturesof return air and fresh air. The units are available with air flow in three modes: high, standard and reduced andcan be further customized with the choice of accessories (optional) especially designed to meet variousapplication needs.CB - PRINCIPLE OF OPERATION OF STANDARD UNIT (VERSION B)The standard constructional configuration, called version B, allows control of supply and return air flow and theintake of fresh air for required refreshing by means of a manually operated shutter.The version with optional setups is equipped with shutters with a servo-motor for constant adjustment of therefresh air mixture:- operation with a fixed percentage of refresh air with opening or closing of the shutter by means of an actuator(ON-OFF) which intervenes when ventilation is active (optional)- operation with variable percentage of refresh air with opening and closing of the shutters by means ofmodulating actuators driven by the signal of the air quality probe (optional)- operation with variable percentage of refresh air with opening and closing of the shutters by means ofmodulating actuators, which intervene when the fresh air conditions are such that they allow lowering of internalthermal loads simply by placing primary air in the room (free-cooling B) (optional).CONFIGURATION B STANDARD OR WITHSHUTTER ON-OFFCONFIGURATION B WITH FREECOOLING VERSION BSUPPLY +70%RETURN SUPPLY +70%RETURN-30%-MAN30%FRESH AIRAUTFRESH AIRCC - OPTIONAL VERSION WITH AIR EXPULSION AND FREE-COOLINGWhen the machine is in optional constructive configuration (called version C), it allows automatic management ofthe supply and return air flows, and the intake of fresh air for required refreshing. In addition, it is capable ofpartially or entirely expelling the return air by means of dedicated fans.The automatic adjustment of the shutters allows operation of the unit:- with full recirculation- with a mixture of re-circulation air and fresh air- with continuous adjustment of the flow rates of fresh and expelled air (modulating free-cooling);- with all fresh air and total expulsion of return air (total free-cooling).CONSTRUCTIONAL CONFIGURATION CEXHAUST AIRSUPPLY+-30%30%70%RETURNFRESH AIR3

BT08L005GB-01PACKAGED362 - 904FC - THERMAL FREE COOLING (construction configuration C)As soon as external conditions allow it, the unit is capable of automatically activating free-cooling mode, which, bykeeping the compressors off and drawing in suitably filtered fresh air, cools the served room. The fresh air flowcan be varied based on actual needs. This operating mode is especially useful in spring and autumn or with highambient loads. It allows substantial reduction of the unit's energy consumption and wear of the compressors.CONFIGURATION CODE(1)(2) (3)(4)(5)(6)(7)CRH - XHE C 452 M 200R100SMSRBSMSRCRMRRHMHR(1) CONSTRUCTIONAL CONFIGURATIONrecirculated/outside air mixing box (B)free cooling version with extract/recirculated/fresh air intake box (C)(2) SUPPLYStandard (S)(3) OUTLET STATIC PRESSURE VALUEOUTLET STATIC PRESSURE VALUE(4) RETURNStandard (S)(5) INTAKE STATIC PRESSURE VALUE(6) AIR FLOWStandard air flow (SM)Reduced air flow (RM)Air flow high (HM)(7) INTAKE AIR FLOWStandard air flow (SR)Reduced air flow (RR)Air flow high (HR)FILTRATIONStandard units are standard equipped with a suitable filtering sectioncomposed of pleated filters, class G4, with an ample surface. They are easilyaccessible for periodic maintenance.UPDATED ELECTRONIC CONTROLThe operation of the unit is fully automatic thanks to the Clivet Talk electronicadjustment system. This is a modular device, of automatic origins, with highspeed and reliability and control logic specifically designed for this type ofproduct. The user interface is easy to use. This allows better use of availableresources, extending the life cycle of the components and thus reducingmaintenance costs. With the micro-processor keypad, it is possible to performdaily/weekly programming of the set-point, as well as start-up or shutdown ofthe machine. The unit can also be connected to supervision systems usingclean contacts or by serial with the standards of communication mostcommonly available on the market.CONTROL LOGICS IN THE EVENT OF ALARM SIGNALMachine logics(1)Complete shutdown(2)Room kept depressurizedDescription Standard Version Vers. B withfree-cooling optionsupply fanreturn fanFresh air ShutterDischarge damperRecirculation shuttersupply fanreturn fanFresh air ShutterDischarge damperRecirculation shuttersupply fanOff Off Off- - OffOpen- --- - Off- - On- -- -- -ClosedClosedVersion COn On OnClosedClosedClosedClosedOpenClosedreturn fan- - Off(3)Room kept pressurized Fresh air ShutterOpenOpen OpenDischarge damper- -ClosedRecirculation shutter-ClosedClosedThe machine logic manages the signal from the smoke detector installed in the return section or by a fire detection unit, implementing one of the actions shown in the table which can be set as aparameter. If there is an alarm signal and according to the set logic, the compressors are always shut off. The roof-top units may not be used as smoke extractors.4

AVAILABLE POWERBT08L005GB-01OUTSIDE TEMPERATURE PROBEThe measurement of the temperature of outside air is an essentialparameter of heat adjustment. It takes place via a probe located in aspecial compartment that connects the external environment andthe return duct (always in negative pressure). Clivet has chosen thissolution to ensure correct measurement of temperature since theprobe is constantly in contact with a minimum flow of air. Onrequest, the temperature probe can be integrated with the optionalhumidity probe).INTAKE DUCTPACKAGED362 - 904FRESH AIROUTSIDE TEMPERATURE PROBEELECTRONIC EXPANSION VALVEThe electronic expansion valve is an essential component of the refrigerant circuit.It offers a number of advantages as compared to the traditional thermostatic valve.These include:- reduction of overheating temperature (greater efficiency of refrigerant circuit)- improved compressor working conditions (COP optimized)- reduction of pressure at condenser (less energy absorbed by compressors)- reduction of output temperature of the compressor- adaptation to all load conditions and transitories without causing swinging at partialloadsAll this aids in increasing the efficiency of the load for any thermal load condition and toextend the life cycle.LOW EFFICIENCYDANGER OF BREAKAGE OVERHEATINGHIGH EFFICIENCYOPTIMAL OPERATIONP = Provided Power VariationEEV= Electronic valveTEV = Thermostatic valveDEMAND LIMITLOW EFFICIENCYDANGER OF BREAKAGE PRESENCE OF LIQUIDThe Demand Limit function is a logic that controls the machine's resources dedicated to limiting the input powerfrom the electrical mains (for example when there are special agreements between the user and the operator ofthe electrical mains) or to selecting the thermal resources to be used based on special needs of the client. TheDemand Limit device can control and manage the available steps of thermal power by means of the receipt of anexternal analogue signal, 0-10V/4-20mA. The control logic does not act on the ventilation which is thereforealways ensured. The greater the input signal to the Demand Limit, the less the thermal power available for thesystem. In the extreme condition of pilot signal at 100%, the system can also shut off the last power step.[kW]AS THE DEMAND LIMIT SIGNAL INCREASES, THEPOWER STEPS ARE GRADUALLY DISABLED. WHEN THESIGNAL IS AT 100%, ALL AVAILABLE RESOURCES AREDISABLED.AUXILIARY ELECTRIC HEATING ELEMENTS60 2.5 5 7.5 10 [V]SIGNAL 0-10V DC5

BT08L005GB-01EERPACKAGED362 - 904PANELLINGThe need to improve access to the internal parts of the machine for theordinary maintenance and at the same time the need to give structuralstiffness and increase thermal insulation has brought to the adoption of"sandwich" type panels on all units. The roof and the structure of the airtreatment area are made with such panels with dual steel walls withpolyurethain foam and feature seal gaskets alongside the ledge. Thepanels are hinged and feature handles and closures with adjustableclamping.VERY HIGH EFFICIENCY AT PARTIAL LOADIn air conditioning projects, the choice of the unit is made based on the maximum load of the room to be served.In practice, over the course of the year these operating conditions are limited to short periods of time, whereasoperation at partial loads is the actual normal operating condition. The need to adapt the power provided to theload requested becomes essential in limiting energy consumption. This is why we have decided to couple twoscroll compressors of different power on a single refrigeration circuit, thus obtaining very high efficiency. Theelectronic control that the machine is equipped with divides compressor operation into three steps of power (1/3,2/3, 3/3). This limits the oscillation of the air temperature, and provides perfect adaptation to partial load, offeringsubstantial energy savings.9876% Working Time100%90%80%70%For 70% of thetime the load isunder 50%For 90% of thetime the load isunder 80%60%550%440%330%220%110%(1)(2) (3)0(1) (2) (3)0%

BT08L005GB-01PACKAGED362 - 904STANDARD UNIT SPECIFICATIONSCOMPRESSORScroll compressor complete with: overload thermal protection, high refrigerantdischarge temperature, rubber antivibration mounts, oil charge.A oil heater is automatically switched on at the compressor shut-down to preventoil dilution by the refrigerant.The compressors are connected in tandem on a single refrigerator circuit. Theyhave bi-phase equalization of the oil and are equipped with cut-off bibcocksA oil heater is automatically switched on at the compressor shut-down to preventoil dilution by the refrigerant.STRUCTUREThe basement is assembled with a painted galvanized steel frame. The internalstructure is made of “ALUZINK” bent galvanized steel . The alloy that protects theAluzink allow an excellent corrosion proofing thanks to the galvanic protectiontypical of the combination aluminium-zinc.PANELLINGPanels of the compressor panel in steel sheet metal, painted using polyesterpowders, colour RAL 9001 and covered on the inside with ashlared soundabsorbentmaterial.Sandwich panels in the air treatment section with dual walls in steel sheet metalwith polyurethane insulation (40 kg/m3), thickness of outer sheet metal 6/10 mmgalvanized and painted using polyester powders colour RAL 9001, polyurethanethickness with thermal conductivity coefficient 0.022W/mK, thickness of internalsheet metal 5/10 mm hot galvanized. The panel is also provided with a PVCprofile for thermal insulation and a EPDM rubber gasket that ensures the hermeticseal.All panelling can easily be removed to allow complete accessibility to internalcomponents.INTERNAL EXCHANGERDirect expansion finned exchanger, made from copper pipes in staggered rowsand mechanically expanded to the fin collars. The fins are made from aluminiumwith a corrugated surface and adequately distanced to ensure the maximum heatexchange efficiency.EXTERNAL EXCHANGERDirect expansion heat exchanger with braze welded stainless steel AISI 316plates and complete with external thermal/anti-condensation insulation, completewith water side differential pressure switch and water temperature control probe.FANSUPPLY FANCentrifugal fan with double intake, blades curved forward to achieve maximumperformance and silence. Statically and dynamically balanced as per standardsISO 1940 degree 6.3. Fastened to rubber anti-vibration devices. The screw, rotorand frame are made of galvanized sheet metal (semdzimir) the shaft is made ofC40 steel. Connection to electric motor with belt and pulleys.REFRIGERANT CIRCUITThe circuit is complete with:- refrigerant charge- sight glass with moisture indicator- high pressure switch- low pressure switch- filter dryer- electronic expansion valve- non-return valve- 4-way reverse cycle valve- liquid receiver- high pressure safety valve- low pressure safety valveFILTRATIONPleated filter for greater filtering surface, made up of galvanized plate frame withgalvanized and electric-welded protective mesh, and regenerable filtering mediamade from polyester fibre sized with synthetic resins. G4 efficiency according toCEN-EN 779 standard (Eurovent class EU4/5 - average efficiency 90.1% A-SHRAE 52-76 Atm). Self-extinguishing (resistance to fire class 1 - DIN 53438).For units up to size 452: additional filter G4 on the fresh air intake.- clean contacts for remote ON-OFF, cumulative alarm, fan status, compressorstatus, summer/winter mode- control keypad, including:display of the parameter indexdisplay of the set values and the error codesMENU button to jump to the main menuALARM button to access the alarm management functionsstatus button to display the status listunit operation or ventilation only selection buttonOn/Off and manual reset button for overload device activationUP and DOWN buttons to increase and decrease the valuesSelected function signal LEDCompressor timer / operation signal LEDRETURN FAN(Constructional configuration C)Centrifugal fan with double intake, blades curved forward to achieve maximumperformance and silence. Statically and dynamically balanced as per standardsISO 1940 degree 6.3. Fastened to rubber anti-vibration devices. The screw, rotorand frame are made of galvanized sheet metal (semdzimir) the shaft is made ofC40 steel. Connection to electric motor with belt and pulleys.External sectionHelical fans with shaped aluminium blades, directly coupled to the three-phaseelectric motor, with built-in thermal overload protection, minimum IP 54 construction.Mounted in aerodynamic housings to increase efficiency and minimise noiselevels, and fitted with safety grills.TESTUnit manufactured according to the ISO 9001 quality standards and subject tofunctional testing at the end of the production lineACCESSORIES- copper / copper evaporator coils- 2 rows hot water coil- modulating three-way valve- hot gas re-heating coil- Copper / copper hot gas re-heating coil- electrode boiler steam humidifier- water to waste evaporating wet-deck humidifier- Electric heaters.- Air quality sensor for CO2 p.p.m. control- Air quality sensor for CO2 and VOC p.p.m. control- bag filters section F7 class- High efficiency electrostatic filters additional section- differential pressure switch for dirty air filters- high and low pressure gauges- Active regeneration circuit on exhaust air- Plumbing assembly for loop with constant flow rate- Plumbing assembly for loop with variable flow rate- Plumbing assembly for system with disposable water- Antifreeze heater protection on the water side exchanger- Steel mesh filter on the water side (separately supplied accessories)- free-cooling with temperature comparison only (standard for version C)- free-cooling with independent comparison of temperature and absolute humidity- On/off motorized air outlet damper (only for B version)- Modulating air outlet damper (only for B version)- Disposal for inrush current reductionFans- Application with fabric ducts (only for C version)- high and low pressure gauges- smoke detector- phase monitor- power factor correction capacitors (cosfi > 0.9)- serial port RS485 with LONWORK protocol- serial port RS485 with MODBUS protocol- Remote control with remote microprocessor control (separately supplied accessories)TRAYCondensation collection basin in aluminium alloy 1050 H24 with anticondensationinsulation, welded and equipped with siphoned drain tubeELECTRICAL PANELthe electrical panel is situated inside the units and is accessed through a hingeddoor that is opened by a special keyThe Power Section includes:- main door lock isolator switch- compressor circuit breaker- compressor power supply remote control switch- fan motor thermal overload protection on air handlingcoil side- circuit breaker to protect auxiliary circuitmicroprocessor control section:- treated air temperature control- compressor overload protection and timer- centralised alarms with remote signalling- self-diagnosis system with immediate display of the error code- demand limit7

BT08L005GB-01PACKAGED362 - 904AIR FLOW: STANDARDGENERAL TECHNICAL SPECIFICATIONSSize 362 402 452 464 524 604 704 804 904COOLINGCooling capacity 1 kW 121,4 135,7 147,3 161,7 183,8 211,2 239,4 285,3 314,6Sensible capacity 1 kW 90,1 99,7 109,2 123,6 139,1 157,9 177 216,2 236,4Compressor power input 1 kW 22 24,8 28,1 28 33,2 37,9 43,8 50 56,7EER 1 5,53 5,47 5,25 5,77 5,53 5,57 5,47 5,7 5,55HEATINGHeat output 2 kW 134,2 152,6 168 178,7 205,1 231,8 266,7 311,6 344,2Compressor power input 2 kW 24,1 28,2 32 31,3 37,6 41,1 49,2 53,1 59,9COP 2 5,57 5,42 5,25 5,72 5,45 5,63 5,42 5,87 5,74COMPRESSORType of compressors 3 Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll ScrollNo. of Compressors Nr 2 2 2 4 4 4 4 4 4Std Capacity control steps Nr 3 3 3 6 6 4 6 6 6Refrigerant circuits Nr 1 1 1 2 2 2 2 2 2AIR HANDLING SECTION FANS (OUTLET)Type of fans 4 CFG CFG CFG CFG CFG CFG CFG CFG CFGNumber of fans Nr 1 1 1 1 1 1 1 1 1Number of impellers Nr 2 2 2 2 2 2 2 2 2Air flow l/s 5555 6111 6666 8056 9028 10000 11111 12500 13888Installed unit power kW 7,5 7,5 9 9 11 15 18,5 18,5 22Max outside static pressure 5 Pa 300 210 210 240 210 330 300 330 270Max outside static pressure 6 Pa 570 570 570 570 570 510 570 570 570FANS (RETURN)Type of fans 7 CFG CFG CFG CFG CFG CFG CFG CFG CFGNumber of fans Nr 1 1 1 1 1 1 1 1 1Air flow l/s 4444 4888 5333 6444 7222 8000 8889 10000 11111Installed unit power kW 3 3 4 4 5,5 7,5 7,5 7,5 11Max outside static pressure 8 Pa 210 120 120 150 180 240 120 120 210Max outside static pressure 9 Pa 450 450 450 420 420 450 450 450 450EXTERNAL EXCHANGERWater flow rate (External Exchanger) l/s 6,9 7,7 8,4 9,1 10,4 11,9 13,5 16 17,7POWER SUPPLYStandard power supply V 400/3/50 400/3/50 400/3/50 400/3/50 400/3/50 400/3/50 400/3/50 400/3/50 400/3/50Performance refers to operation at full re-circulation(1) data referred to the following conditions :Ambient temperature 27°C/19.5 WBwater to internal exchanger 30/35°CWB = wet bulbEER referred only to compressors(2) data referred to the following conditions :ambient temperature 20°C DBexchanger water outlet 10°CDB = dry bulbCOP referred only to compressors(3) SCROLL = scroll compressor(4) CFG = centrifugal fan(5) with standard electric motor(6) with uprated electric motors(7) Constructional configuration CCFG = centrifugal fan(8) with standard electric motor(9) with uprated electric motors8

BT08L005GB-01PACKAGED362 - 904ELECTRICAL DATACONSTRUCTIONAL CONFIGURATION: MIXING BOX FOR RECYCLE /FRESH AIR (B)Size 362 402 452 464 524 604 704 804 904F.L.A. - FULL LOAD CURRENT AT MAX ADMISSIBLE CONDITIONSF.L.A. - Compressor 1 A 36,5 44,9 44,9 30,6 30,6 30,6 36,5 44,9 44,9F.L.A. - Compressor 2 A 30,6 30,6 36,5 15,2 22,6 30,6 30,6 30,6 36,5F.L.A. - Compressor 3 A - - - 30,6 30,6 30,6 36,5 44,9 44,9F.L.A. - Compressor 4 A - - - 15,2 22,6 30,6 30,6 30,6 36,5F.L.A. - Single supply fan 1 A 14,9 14,9 19 19 21 28,5 35 35 41F.L.A. - Total 2 A 67,6 76 81,9 92,1 106,9 122,9 134,7 151,5 163,3L.R.A. LOCKED ROTOR AMPERESL.R.A. - Compressor 1 A 225 272 272 173 173 173 225 272 272L.R.A. - Compressor 2 A 173 173 225 95 118 173 173 173 225L.R.A. - Compressor 3 A - - - 173 173 173 225 272 272L.R.A. - Compressor 4 A - - - 95 118 173 173 173 225L.R.A. - Single supply fan A 113,2 113,2 144,4 144,4 159,6 216,6 266 245 295,2F.L.I. FULL LOAD POWER INPUT AT MAX ADMISSIBLE CONDITIONF.L.I. - Compressor 1 kW 22,6 27,3 27,3 17 17 17 22,6 27,3 27,3F.L.I. - Compressor 2 kW 17 17 22,6 8,9 13,2 17 17 17 22,6F.L.I. - Compressor 3 kW - - - 17 17 17 22,6 27,3 27,3F.L.I. - Compressor 4 kW - - - 8,9 13,2 17 17 17 22,6F.L.I. - Single supply fan 3 kW 7,5 7,5 9 9 11 15 18,5 18,5 22F.L.I. - Total 4 kW 39,9 44,6 50,2 52,1 60,7 68,3 79,5 88,9 100,1power supply: 400/3/50 Hz +/-6%voltage unbalance: max 2 %Values not including accessories(1) n.d. = not definedThe input of the fan motors is shown in the performance tables of the fansThe installed motor must be determined taking into consideration the air flow rate and theusable static pressure(2) value including all standard components of the unitcontrol circuit includedThis data does not take into consideration the motors of the zone treatment fans nor theaccessoriesto obtain the overall F.L.A. value, add the total F.L.A. value to that of any accessories (seeelectrical data of accessories) and that of the motors of the treatment area fans (see table offan performance)(3) n.d. = not definedThe input of the fan motors is shown in the performance tables of the fansThe installed motor must be determined taking into consideration the air flow rate and theusable static pressure(4) value including all standard components of the unitcontrol circuit includedThis data does not take into consideration the motors of the zone treatment fans nor theaccessoriesto obtain the overall F.L.I. value, add the total F.L.I. value to that of any accessories (seeelectrical data of accessories) and that of the motors of the treatment area fans (see table offan performance)CONSTRUCTIONAL CONFIGURATION: FREE COOLING VERSION WITH EXTRACT/RECIRCULATED/FRESH AIR INTAKE BOX (C)ELECTRICAL DATASize 362 402 452 464 524 604 704 804 904F.L.A. - FULL LOAD CURRENT AT MAX ADMISSIBLE CONDITIONSF.L.A. - Compressor 1 A 36,5 44,9 44,9 30,6 30,6 30,6 36,5 44,9 44,9F.L.A. - Compressor 2 A 30,6 30,6 36,5 15,2 22,6 30,6 30,6 30,6 36,5F.L.A. - Compressor 3 A - - - 30,6 30,6 30,6 36,5 44,9 44,9F.L.A. - Compressor 4 A - - - 15,2 22,6 30,6 30,6 30,6 36,5F.L.A. - Single supply fan 1 A 14,9 14,9 19 19 21 28,5 35 35 41F.L.A. - Single Inlet fan 1 A 6,5 6,5 8,3 8,3 11,2 14,9 14,9 19 21F.L.A. - Total 2 A 67,6 76 81,9 92,1 106,9 122,9 134,7 151,5 163,3L.R.A. LOCKED ROTOR AMPERESL.R.A. - Compressor 1 A 225 272 272 173 173 173 225 272 272L.R.A. - Compressor 2 A 173 173 225 95 118 173 173 173 225L.R.A. - Compressor 3 A - - - 173 173 173 225 272 272L.R.A. - Compressor 4 A - - - 95 118 173 173 173 225L.R.A. - Single supply fan A 113,2 113,2 144,4 144,4 159,6 216,6 266 245 295,2L.R.A. - Single Intake fan A 49,4 49,4 63,1 63,1 85,1 113,2 113,2 144,4 151,2F.L.I. FULL LOAD POWER INPUT AT MAX ADMISSIBLE CONDITIONF.L.I. - Compressor 1 kW 22,6 27,3 27,3 17 17 17 22,6 27,3 27,3F.L.I. - Compressor 2 kW 17 17 22,6 8,9 13,2 17 17 17 22,6F.L.I. - Compressor 3 kW - - - 17 17 17 22,6 27,3 27,3F.L.I. - Compressor 4 kW - - - 8,9 13,2 17 17 17 22,6F.L.I. - Single supply fan 3 kW 7,5 7,5 9 9 11 15 18,5 18,5 22F.L.I. - Single Inlet fan 3 kW 3 3 4 4 5,5 7,5 7,5 9 11F.L.I. - Total 4 kW 39,9 44,6 50,2 52,1 60,7 68,3 79,5 88,9 100,1power supply: 400/3/50 Hz +/-6%voltage unbalance: max 2 %Values not including accessories(1) n.d. = not definedThe input of the fan motors is shown in the performance tables of the fansThe installed motor must be determined taking into consideration the air flow rate and theusable static pressure(2) value including all standard components of the unitcontrol circuit includedThis data does not take into consideration the motors of the zone treatment fans nor theaccessoriesto obtain the overall F.L.A. value, add the total F.L.A. value to that of any accessories (seeelectrical data of accessories) and that of the motors of the treatment area fans (see table offan performance)(3) n.d. = not definedThe input of the fan motors is shown in the performance tables of the fansThe installed motor must be determined taking into consideration the air flow rate and theusable static pressure(4) value including all standard components of the unitcontrol circuit includedThis data does not take into consideration the motors of the zone treatment fans nor theaccessoriesto obtain the overall F.L.I. value, add the total F.L.I. value to that of any accessories (seeelectrical data of accessories) and that of the motors of the treatment area fans (see table offan performance)9

BT08L005GB-01PACKAGED362 - 904ELECTRICAL INPUT OF OPTIONAL COMPONENTSTo obtain the electrical input of the unit including accessories, add the standard data in Electrical Data table tothose for the selected accessories.GRANDEZZE 362 402 452 464 524 604 704 804 904F.L.A. CORRENTE ASSORBITAF.L.A. EH20 - Resistenze elettriche di riscaldamento da 24 kWF.L.A. EH24 - Resistenze elettriche di riscaldamento da 36 kWF.L.A. EH28 - Resistenze elettriche di riscaldamento da 48 kWF.L.A. EH72 - Resistenze elettriche di riscaldamento da 72 kWF.L.A. EH33 - Resistenze elettriche di riscaldamento da 96 kWF.L.A. HSE8 - Umidificatore a vapore ad elettrodi immersi da 8 kg/hF.L.A. HSE9 - Umidificatore a vapore ad elettrodi immersi da 15 kg/hF.L.A. FES - Filtri elettrostastici ad alta efficienza classe H10F.L.I. POTENZA ASSORBITAF.L.I. EH20 - Resistenze elettriche di riscaldamento da 24 kWF.L.I. EH24 - Resistenze elettriche di riscaldamento da 36 kWF.L.I. EH28 - Resistenze elettriche di riscaldamento da 48 kWF.L.I. EH72 - Resistenze elettriche di riscaldamento da 72 kWF.L.I. EH33 - Resistenze elettriche di riscaldamento da 96 kWF.L.I. HSE8 - Umidificatore a vapore ad elettrodi immersi da 8 kg/hF.L.I. HSE9 - Umidificatore a vapore ad elettrodi immersi da 15 kg/hF.L.I. FES - Filtri elettrostastici ad alta efficienza classe H10A 34.6 34.6 34.6 - - - - - -A 52.0 52.0 52.0 52.0 52.0 52.0 52.0 - -A 69.4 69.4 69.4 69.4 69.4 69.4 69.4 69.4 69.4A - - - 104.0 104.0 104.0 104.0 104.0 104.0A - - - 138.6 138.6 138.6 138.6 138.6 138.6A 8.7 8.7 8.7 - - - - - -A 16.2 16.2 16.2 16.2 16.2 16.2 16.2 16.2 16.2A 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2kW 24 24 24 - - - - - -kW 36 36 36 36 36 36 36 - -kW 48 48 48 48 48 48 48 48 48kW - - - 72 72 72 72 72 72kW - - - 96 96 96 96 96 96kW 6 6 6 - - - - - -kW 11.25 11.25 11.25 11.25 11.25 11.25 11.25 11.25 11.25kW 0.5 0.5 0.5 1 1 1 1 1.25 1.25CALCULATION OF BREAKAWAY CURRENT (M.I.C.)The calculation of the breakaway current (M.I.C.) is necessary in order to size the protection up the electrical linefrom the unit. Its value depends on the selected configuration and the components selected (motor sizes). TheM.I.C. is obtained by summing the maximum breakaway current (L.R.A.) of the largest compressor and the inputcurrent at the maximum admissible conditions (F.L.A.) of the remaining electrical components.M.I.C. = L.R.A.(C1) + F.L.A.(C2) + F.L.A.(C3) + F.L.A.(C4) + F.L.A.(Fan Intake) + F.L.A.(Fan Return)L.R.A. (C1) = breakaway current of the larger size compressor (Tandem 1).F.L.A. (C2) = input current of the smaller size compressor (Tandem 1).F.L.A. (C3) = input current of the larger size compressor (Tandem 2).F.L.A. (C4) = input current of the smaller size compressor (Tandem 2).F.L.A.(Fan Intake) = input current of supply fan.F.L.A.(Fan Return) = input current of return fan (only for version C).Example of calculation of the M.I.C. for units size 464 configuration C with standard supply fan (9 kW) and standard return fan (4 kW):M.I.C. = 173 + 15.2 + 30.6 + 15.2 + 9 + 4 = 247 ATANDEM 1 TANDEM 2C1 C2 C3 C410

SizeBT08L005GB-01To D.B. [°C]Ta W.B. [°C]PACKAGED362 - 904OPERATING LIMITS (COOLING)30252015105(2)10 15 20 25 30 35 40 45 50T H 2 O [°C](1)THE LIMITS ARE INDICATIVE AND HAVE BEEN CALCULATED CONSIDERING:- VALUES GENERAL AND NOT SPECIFICATIONS,- STANDARD AIR FLOW-RATE,- NON-CRITICAL POSITIONING AND CORRECT USE OF THE UNIT,- OPERATION AT FULL LOAD(-) DIFFERENCE BETWEEN INLET / OUTLET WATER TEMPERATURE = 5°CWITH UNIT OPERATING IN INTAKE OF OUTSIDE AIR CALCULATE THE TEMPERATU-RES OF MIXES WHICH ARE GENERATED FROM THE EXCHANGERS' INLET TO KNOWTHE LIMITS.TA = INTERNAL EXCHANGER INLET AIR TEMPERATURE W.B. (°C)WB = WET BULBTH20 = WATER LOOP TEMPERATURE (°C)(-) INTERNAL EXCHANGER WATER INLET(1) THE DASHED AREA REFERS TO THE FIELD OF UNITS OPERATIONSTANDARD(2) THE AREA WITH THE DOTTED OUTLINE IDENTIFIES THE FIELD OF OPERATION OFTHE UNITS WITH PLUMBING ASSEMBLY FOR A SYSTEM WITH DISPOSABLE WATER(OPTIONAL)OPERATING LIMITS (HEATING)302520151050-5-10(2) (1)(3)0 5 10 15 20 25 30 35 40T H 2 O [°C]THE LIMITS ARE INDICATIVE AND HAVE BEEN CALCULATED CONSIDERING:- VALUES GENERAL AND NOT SPECIFICATIONS,- STANDARD AIR FLOW-RATE,- NON-CRITICAL POSITIONING AND CORRECT USE OF THE UNIT,- OPERATION AT FULL LOAD(-) DIFFERENCE BETWEEN INLET / OUTLET WATER TEMPERATURE = 5°CWITH UNIT OPERATING IN INTAKE OF OUTSIDE AIR CALCULATE THE TEMPERATU-RES OF MIXES WHICH ARE GENERATED FROM THE EXCHANGERS' INLET TO KNOWTHE LIMITS.TO = TEMPERATURE OF AIR ENTERING THE INTERNAL EXCHANGER D.B.(°C)DB = DRY BULBTH20 = WATER LOOP TEMPERATURE (°C)(-) INTERNAL EXCHANGER WATER INLET(1) THE DASHED AREA REFERS TO THE FIELD OF UNITS OPERATIONSTANDARD(2) THE DASHED AREA INDICATES THE OPERATING RANGE WITH WATER WITHGLYCOL ADDED TO PREVENT FREEZING(3) THE AREA WITH THE DOTTED OUTLINE IDENTIFIES THE FIELD OF OPERATION OFTHE UNITS WITH PLUMBING ASSEMBLY FOR A SYSTEM WITH DISPOSABLE WATER(OPTIONAL)SOUND LEVELSAir flow: standardSound Power Level (dB)Octave band (Hz)SoundpressurelevelSoundpower level63 125 250 500 1000 2000 4000 8000 dB(A) dB(A)362 89 82 88 85 85 81 76 67 69 89402 90 83 89 86 85 82 76 64 70 89452 91 84 90 87 86 83 77 66 71 90464 99 95 98 88 84 75 70 67 72 92524 104 95 95 91 87 81 76 73 73 93604 104 95 95 91 87 81 76 73 73 93704 106 96 95 92 87 81 76 74 73 93804 105 98 98 91 90 83 77 76 74 95904 106 100 99 93 91 84 78 77 75 96the sound levels refer to the unit at full load, in the rated test conditions.The sound pressure level refers to a distance of 1m from the external surface ofthe units operating in an open field.standard 50 Pa static pressure(standard UNI EN ISO 3744)Please note that when the unit is installed in conditions other than nominal testconditions (e.g. near walls or obstacles in general), the sound levels may undergosubstantial variations.11

BT08L005GB-01PACKAGED362 - 904AIR FLOW: STANDARDSize 362 402 452 464 524 604 704 804 904Air flow l/s 5555 6111 6666 8056 9028 10000 11111 12500 13888COOLING PERFORMANCESizeTa(°C)DB/WBTEMPERATURE OF WATER LEAVING THE EXTERNAL HEAT EXCHANGER (°C) - TEMPERATURE DIFFERENTIAL 5°C25 30 35 40 45 50kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs36240245246452422 / 1624 / 1726 / 1927 / 19,528 / 2130 / 2222 / 1624 / 1726 / 1927 / 19,528 / 2130 / 2222 / 1624 / 1726 / 1927 / 19,528 / 2130 / 2222 / 1624 / 1726 / 1927 / 19,528 / 2130 / 2222 / 1624 / 1726 / 1927 / 19,528 / 2130 / 2222 / 1624 / 17117,1 18,0 86,8 113,1 19,6 84,6 108,7 21,6 82,5 104,0 23,9 80,3 99,0 26,5 78,2 93,6 29,5 76,1120,7 18,2 92,3 116,7 19,8 90,1 112,3 21,7 87,9 107,4 24,0 85,7 102,2 26,6 83,4 96,7 29,5 81,2128,3 18,4 92,1 124,1 20,0 89,8 119,6 21,9 87,5 114,6 24,2 85,2 109,2 26,8 83,0 103,3 29,7 80,7130,2 18,5 94,7 126,1 20,0 92,4 121,5 22,0 90,1 116,5 24,2 87,9 111,0 26,8 85,6 105,0 29,8 83,3136,2 18,7 91,3 132,0 20,2 89,0 127,4 22,1 86,7 122,2 24,4 84,4 116,6 27,0 82,2 110,5 29,9 79,9140,3 18,8 95,9 136,1 20,3 93,6 131,4 22,2 91,3 126,2 24,5 89,1 120,5 27,1 86,8 114,3 30,0 84,5129,8 20,3 95,8 125,9 22,2 93,5 121,4 24,4 91,2 116,5 27,0 88,8 111,0 29,9 86,5 105,0 33,1 84,1133,9 20,4 102,0 130,0 22,3 99,6 125,4 24,5 97,2 120,2 27,1 94,8 114,5 30,0 92,4 108,1 33,2 90,1142,5 20,7 101,7 138,4 22,5 99,2 133,6 24,7 96,8 128,1 27,3 94,4 121,9 30,2 91,9 114,9 33,4 89,5144,7 20,8 104,6 140,5 22,6 102,1 135,7 24,8 99,7 130,1 27,3 97,2 123,8 30,2 94,8 116,8 33,4 92,4151,3 21,0 100,8 147,1 22,8 98,4 142,1 25,0 95,9 136,4 27,5 93,5 129,9 30,3 91,0 122,7 33,5 88,6155,9 21,1 105,9 151,6 22,9 103,5 146,6 25,1 101,1 140,8 27,6 98,6 134,2 30,4 96,2 126,9 33,6 93,8141,8 23,1 104,8 137,5 25,1 102,0 132,6 27,5 99,1 127,0 30,4 96,3 120,6 33,6 93,4 113,6 37,2 90,6146,0 23,2 111,6 141,7 25,2 108,7 136,6 27,7 105,8 130,9 30,5 102,9 124,5 33,7 100,0 117,3 37,4 97,1155,2 23,4 111,9 150,5 25,5 108,9 145,1 28,0 106,0 139,1 30,8 103,0 132,5 34,0 100,1 125,2 37,6 97,2157,7 23,5 115,1 152,8 25,6 112,2 147,3 28,1 109,2 141,2 30,9 106,3 134,5 34,1 103,3 127,3 37,7 100,4165,6 23,7 110,5 160,0 25,8 107,6 154,0 28,3 104,7 147,7 31,1 101,7 140,9 34,3 98,8 133,8 37,9 95,9171,1 23,8 114,6 165,0 26,0 111,7 158,7 28,5 108,9 152,1 31,3 106,0 145,4 34,5 103,2 138,4 38,0 100,3155,0 22,7 117,1 150,3 24,9 114,7 145,0 27,6 112,3 139,2 30,7 109,9 133,0 34,2 107,5 126,1 38,3 105,1159,9 22,9 124,7 155,1 25,0 122,2 149,7 27,7 119,8 143,7 30,8 117,4 137,1 34,3 114,9 129,9 38,3 112,5170,0 23,2 124,4 165,0 25,3 121,9 159,3 27,9 119,4 153,0 30,9 117,0 146,0 34,4 114,5 138,4 38,4 112,0172,7 23,3 128,5 167,5 25,4 126,0 161,7 28,0 123,5 155,4 31,0 121,1 148,4 34,5 118,6 140,8 38,4 116,1180,6 23,6 125,1 175,1 25,7 122,6 169,2 28,2 120,1 162,7 31,1 117,6 155,8 34,6 115,1 148,4 38,4 112,6186,1 23,8 134,4 180,3 25,8 131,9 174,2 28,3 129,4 167,7 31,2 126,8 160,9 34,6 124,3 153,8 38,5 121,8176,3 27,0 131,3 170,8 29,7 128,3 164,7 32,8 125,4 157,9 36,4 122,4 150,5 40,5 119,4 142,4 45,1 116,5181,5 27,2 140,5 176,1 29,8 137,5 170,0 32,9 134,5 163,1 36,5 131,5 155,5 40,6 128,5 147,1 45,1 125,5192,6 27,6 141,0 187,2 30,1 137,9 180,9 33,1 134,9 173,7 36,7 131,8 165,6 40,7 128,7 156,6 45,3 125,6195,6 27,7 145,3 190,1 30,2 142,2 183,8 33,2 139,1 176,4 36,7 136,1 168,2 40,8 133,0 159,0 45,3 129,9204,8 28,0 138,5 199,1 30,5 135,3 192,4 33,4 132,2 184,7 36,9 129,0 176,0 40,9 125,9 166,2 45,4 122,7211,2 28,2 142,8 205,3 30,6 139,6 198,4 33,6 136,4 190,4 37,0 133,2 181,3 41,0 130,0 171,1 45,6 126,8202,6 31,0 151,9 196,6 33,9 148,5 189,7 37,3 145,1 181,9 41,4 141,7 173,3 46,2 138,3 163,7 51,5 134,9208,8 31,3 161,4 202,7 34,1 158,0 195,7 37,5 154,6 187,7 41,6 151,1 178,8 46,3 147,7 169,0 51,6 144,260470426 / 1927 / 19,528 / 2130 / 2222 / 1624 / 1726 / 1927 / 19,528 / 21221,6 31,8 160,3 215,3 34,5 156,8 208,0 37,8 153,2 199,8 41,8 149,7 190,6 46,5 146,2 180,5 51,7 142,6224,9 31,9 165,0 218,5 34,6 161,4 211,2 37,9 157,9 202,9 41,9 154,3 193,7 46,5 150,8 183,6 51,8 147,2235,1 32,3 159,5 228,4 35,0 155,9 220,9 38,2 152,2 212,5 42,1 148,6 203,3 46,6 145,0 193,2 51,8 141,3242,1 32,6 169,4 235,2 35,2 165,7 227,5 38,4 162,0 219,0 42,2 158,4 209,9 46,7 154,7 200,0 51,8 151,0229,4 36,0 170,6 222,2 39,2 166,3 214,1 43,1 162,0 205,1 47,6 157,7 195,2 52,9 153,4 184,4 58,8 149,0236,7 36,2 181,6 229,4 39,4 177,2 221,2 43,3 172,7 211,9 47,8 168,3 201,7 53,1 163,9 190,5 59,0 159,5251,9 36,7 180,9 244,3 39,8 176,4 235,7 43,7 171,8 226,1 48,2 167,3 215,3 53,4 162,7 203,5 59,4 158,1255,8 36,8 186,1 248,1 40,0 181,6 239,4 43,8 177,0 229,7 48,3 172,4 218,9 53,5 167,8 207,0 59,5 163,3267,9 37,2 179,8 259,7 40,3 175,2 250,6 44,1 170,6 240,6 48,6 166,1 229,8 53,8 161,5 218,0 59,8 156,930 / 22276,2 37,5 189,6 267,6 40,6 185,1 258,2 44,3 180,5 248,1 48,8 176,0 237,3 54,0 171,4 225,8 60,0 166,9Performance refers to operation at full re-circulationTa = input air temperature at treatment (°C)DB = dry bulbWB = wet bulbkWf = Cooling capacity in kWkWs = sensible cooling capacity (kW)kWe = Compressor power input in kWthe cooling capacities have not accounted for the heat dissipation of the centrifugal fan motors.12

BT08L005GB-01PACKAGED362 - 904AIR FLOW: STANDARDCOOLING PERFORMANCESizeTa(°C)DB/WBTEMPERATURE OF WATER LEAVING THE EXTERNAL HEAT EXCHANGER (°C) - TEMPERATURE DIFFERENTIAL 5°C25 30 35 40 45 50kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs80490422 / 1624 / 1726 / 1927 / 19,528 / 2130 / 2222 / 1624 / 1726 / 1927 / 19,528 / 2130 / 22274,8 41,0 204,2 265,8 44,8 199,6 255,9 49,2 195,0 245,1 54,3 190,4 233,5 60,0 185,8 220,9 66,4 181,1283,3 41,3 218,5 274,2 45,0 213,9 264,0 49,4 209,4 252,7 54,5 204,8 240,4 60,2 200,3 227,0 66,7 195,7301,1 41,9 219,0 291,6 45,5 214,4 280,9 49,9 209,7 268,9 54,9 205,1 255,6 60,7 200,4 241,1 67,0 195,8305,6 42,0 225,7 296,1 45,7 220,9 285,3 50,0 216,2 273,2 55,1 211,5 259,8 60,8 206,8 245,0 67,1 202,0319,8 42,5 215,3 310,0 46,1 210,3 299,0 50,5 205,2 286,6 55,4 200,1 272,9 61,1 195,1 258,0 67,3 190,0329,5 42,8 222,6 319,6 46,5 217,2 308,4 50,8 211,8 296,0 55,7 206,4 282,4 61,2 201,0 267,5 67,4 195,6302,4 46,6 226,5 292,6 50,7 220,6 281,5 55,6 214,7 269,0 61,3 208,7 255,2 67,7 202,8 240,0 74,9 196,9312,3 46,9 241,2 302,1 51,0 235,2 290,6 55,9 229,2 277,7 61,6 223,1 263,4 68,0 217,1 247,8 75,2 211,0332,4 47,4 241,6 321,8 51,6 235,4 309,7 56,5 229,2 296,1 62,2 223,0 281,1 68,6 216,8 264,6 75,7 210,6337,6 47,6 248,9 326,8 51,8 242,6 314,6 56,7 236,4 300,9 62,3 230,2 285,7 68,7 224,0 269,0 75,9 217,7353,2 48,0 238,8 342,2 52,2 232,6 329,7 57,2 226,3 315,7 62,8 220,1 300,1 69,2 213,8 283,0 76,3 207,6363,8 48,3 249,0 352,8 52,6 242,7 340,1 57,5 236,5 325,9 63,2 230,3 310,1 69,6 224,1 292,8 76,7 217,8Performance refers to operation at full re-circulationTa = input air temperature at treatment (°C)DB = dry bulbWB = wet bulbkWf = Cooling capacity in kWkWs = sensible cooling capacity (kW)kWe = Compressor power input in kWthe cooling capacities have not accounted for the heat dissipation of the centrifugal fan motors.13

BT08L005GB-01PACKAGED362 - 904AIR FLOW: STANDARDSize 362 402 452 464 524 604 704 804 904Air flow l/s 5555 6111 6666 8056 9028 10000 11111 12500 13888HEATING PERFORMANCETEMPERATURE OF WATER LEAVING THE EXTERNAL HEAT EXCHANGER (°C) - TEMPERATURE DIF-Size Ta (°C)6 8 10 12 14 16kWt kWe kWt kWe kWt kWe kWt kWe kWt kWe kWt kWe3624024524645241015181920212510151819202125101518192021251015181920212510151819202125128,1 19,1 134,4 19,7 140,8 20,2 147,3 20,7 153,9 21,3 160,5 21,9125,3 20,9 131,3 21,4 137,5 22,0 143,8 22,6 150,1 23,2 156,6 23,8123,6 22,1 129,5 22,7 135,5 23,2 141,7 23,8 148,0 24,4 154,4 25,1123,0 22,5 128,9 23,1 134,9 23,7 141,0 24,3 147,3 24,9 153,7 25,5122,5 22,9 128,3 23,5 134,2 24,1 140,3 24,7 146,6 25,3 153,0 26,0121,9 23,4 127,7 24,0 133,6 24,5 139,7 25,2 145,9 25,8 152,3 26,4119,7 25,2 125,3 25,8 131,1 26,4 137,1 27,1 143,3 27,7 149,6 28,4145,8 22,3 152,9 22,9 160,2 23,6 167,5 24,2 174,9 24,9 182,4 25,6142,7 24,4 149,3 25,1 156,2 25,7 163,4 26,4 170,8 27,2 178,4 27,9140,8 25,8 147,3 26,5 154,0 27,2 161,0 27,9 168,3 28,6 175,9 29,3140,2 26,3 146,6 27,0 153,3 27,7 160,3 28,4 167,5 29,1 175,0 29,8139,6 26,8 146,0 27,5 152,6 28,2 159,5 28,9 166,7 29,6 174,1 30,3139,0 27,3 145,4 28,0 152,0 28,7 158,8 29,4 165,9 30,1 173,2 30,8136,6 29,5 143,0 30,2 149,4 30,8 156,0 31,5 162,7 32,2 169,5 32,9160,8 25,5 168,6 26,2 176,5 26,9 184,6 27,7 192,8 28,5 201,1 29,4157,0 27,8 164,4 28,5 172,0 29,3 179,9 30,2 188,1 31,1 196,6 32,0154,9 29,3 162,1 30,1 169,5 30,9 177,3 31,8 185,4 32,7 193,7 33,6154,2 29,9 161,3 30,6 168,7 31,5 176,5 32,3 184,5 33,2 192,7 34,2153,5 30,4 160,6 31,2 168,0 32,0 175,6 32,9 183,5 33,8 191,8 34,7152,8 31,0 159,9 31,8 167,2 32,6 174,8 33,5 182,6 34,4 190,8 35,3150,2 33,3 157,2 34,1 164,3 35,0 171,6 35,8 179,0 36,7 186,7 37,6169,7 24,5 178,0 25,1 186,5 25,8 195,2 26,5 204,1 27,2 213,2 28,0166,0 26,9 174,4 27,6 182,9 28,4 191,5 29,1 200,1 29,8 208,9 30,6164,1 28,6 172,2 29,3 180,4 30,1 188,8 30,8 197,3 31,5 205,9 32,3163,5 29,2 171,5 29,9 179,6 30,6 187,9 31,4 196,3 32,1 204,9 32,9163,0 29,8 170,7 30,5 178,7 31,3 186,9 32,0 195,3 32,7 203,9 33,5162,5 30,5 170,0 31,2 177,8 31,9 185,9 32,6 194,2 33,3 202,8 34,1160,9 33,2 167,2 33,8 174,1 34,5 181,5 35,2 189,6 35,9 198,2 36,7195,3 29,6 204,9 30,4 214,6 31,2 224,5 32,0 234,5 32,9 244,7 33,7191,2 32,6 200,5 33,4 209,9 34,2 219,6 35,1 229,5 35,9 239,6 36,8189,1 34,6 198,0 35,4 207,1 36,2 216,5 37,1 226,1 37,9 236,1 38,8188,5 35,3 197,1 36,1 206,1 36,9 215,4 37,8 225,0 38,6 234,9 39,5187,9 36,0 196,3 36,8 205,1 37,6 214,3 38,5 223,8 39,3 233,6 40,2187,3 36,8 195,5 37,5 204,1 38,3 213,1 39,2 222,5 40,1 232,3 41,0185,2 40,0 192,4 40,6 200,2 41,4 208,4 42,2 217,2 43,1 226,6 44,060410151819202125220,1 32,4 230,9 33,3 241,8 34,1 252,9 35,1 264,1 36,0 275,4 36,9216,1 35,6 226,5 36,5 236,9 37,4 247,6 38,3 258,3 39,2 269,2 40,2213,7 37,8 223,7 38,7 233,9 39,6 244,3 40,5 254,9 41,4 265,6 42,4212,8 38,5 222,7 39,4 232,8 40,3 243,2 41,3 253,7 42,2 264,5 43,1212,0 39,3 221,8 40,2 231,8 41,1 242,1 42,1 252,6 43,0 263,4 43,9211,1 40,1 220,8 41,0 230,7 41,9 240,9 42,9 251,5 43,8 262,3 44,7207,7 43,5 216,7 44,5 226,3 45,4 236,4 46,4 247,0 47,3 258,1 48,2Performance refers to operation at full re-circulationTa = input air temperature at treatment (°C)DB = dry bulbkWt = Heating capacity (kW)kWe = Compressor power input in kWnot all thermal yields take into account the heat dissipated by the fan motors14

BT08L005GB-01PACKAGED362 - 904AIR FLOW: STANDARDHEATING PERFORMANCETEMPERATURE OF WATER LEAVING THE EXTERNAL HEAT EXCHANGER (°C) - TEMPERATURE DIF-Size Ta (°C)6 8 10 12 14 16kWt kWe kWt kWe kWt kWe kWt kWe kWt kWe kWt kWe704804904101518192021251015181920212510151819202125254,6 39,0 267,1 40,0 279,8 41,1 292,6 42,2 305,6 43,4 318,7 44,6249,0 42,6 260,9 43,7 273,2 44,9 285,8 46,1 298,8 47,4 312,2 48,7245,7 45,0 257,3 46,2 269,3 47,4 281,8 48,7 294,7 50,0 308,0 51,4244,6 45,9 256,1 47,1 268,0 48,3 280,4 49,6 293,3 50,9 306,6 52,3243,5 46,8 254,9 47,9 266,7 49,2 279,0 50,5 291,9 51,8 305,2 53,2242,4 47,7 253,7 48,9 265,4 50,1 277,7 51,4 290,5 52,8 303,7 54,2237,9 51,5 248,9 52,7 260,4 54,0 272,3 55,3 284,8 56,8 297,7 58,2296,5 42,3 311,2 43,4 326,3 44,5 341,7 45,7 357,5 46,9 373,6 48,2290,1 46,2 304,4 47,3 319,0 48,5 333,7 49,7 348,7 51,0 363,9 52,3286,4 48,8 300,3 50,0 314,5 51,2 328,9 52,4 343,5 53,7 358,4 55,0285,2 49,7 299,0 50,9 313,0 52,1 327,3 53,4 341,8 54,6 356,6 55,9284,0 50,7 297,6 51,9 311,5 53,1 325,7 54,3 340,2 55,6 354,9 56,9282,8 51,6 296,2 52,8 310,0 54,0 324,1 55,3 338,5 56,5 353,2 57,8278,1 55,7 290,8 56,9 304,0 58,2 317,7 59,4 331,9 60,6 346,7 61,8328,8 48,0 345,1 49,2 361,7 50,4 378,9 51,8 396,4 53,2 414,4 54,7321,1 52,2 336,9 53,5 353,0 54,9 369,5 56,3 386,3 57,8 403,5 59,4316,5 55,1 332,0 56,5 347,7 57,9 363,8 59,3 380,3 60,9 397,1 62,5315,0 56,1 330,3 57,5 346,0 58,9 362,0 60,4 378,3 61,9 394,9 63,5313,5 57,1 328,7 58,5 344,2 59,9 360,1 61,4 376,3 63,0 392,8 64,6312,1 58,2 327,1 59,6 342,5 61,0 358,2 62,5 374,3 64,1 390,8 65,7306,3 62,6 320,6 64,1 335,5 65,5 350,7 67,1 366,4 68,6 382,6 70,2Performance refers to operation at full re-circulationTa = input air temperature at treatment (°C)DB = dry bulbkWt = Heating capacity (kW)kWe = Compressor power input in kWnot all thermal yields take into account the heat dissipated by the fan motors15

BT08L005GB-01PACKAGED362 - 904AIR FLOW: REDUCEDSize 362 402 452 464 524 604 704 804 904Air flow l/s 4444 4888 5333 6389 7222 8056 8889 10000 11111COOLING PERFORMANCESizeTa(°C)DB/WBTEMPERATURE OF WATER LEAVING THE EXTERNAL HEAT EXCHANGER (°C) - TEMPERATURE DIFFERENTIAL 5°C25 30 35 40 45 50kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs36240245246452424 / 1726 / 1927 / 19,528 / 2130 / 2232 / 23,524 / 1726 / 1927 / 19,528 / 2130 / 2232 / 23,524 / 1726 / 1927 / 19,528 / 2130 / 2232 / 23,524 / 1726 / 1927 / 19,528 / 2130 / 2232 / 23,524 / 1726 / 1927 / 19,528 / 2130 / 2232 / 23,524 / 1726 / 19114,4 18,0 83,8 111,2 19,6 81,6 107,5 21,5 79,4 103,2 23,8 77,2 98,3 26,4 75,0 92,9 29,4 72,9122,0 18,2 83,3 118,3 19,8 81,0 114,1 21,7 78,8 109,6 24,0 76,5 104,6 26,6 74,3 99,3 29,6 72,0123,9 18,3 85,4 120,1 19,9 83,2 115,8 21,8 80,9 111,2 24,1 78,7 106,3 26,7 76,4 101,0 29,7 74,1129,8 18,5 83,3 125,6 20,1 81,1 121,2 22,0 78,8 116,5 24,2 76,5 111,5 26,8 74,3 106,2 29,8 72,0133,7 18,6 88,3 129,4 20,2 86,1 124,9 22,1 83,9 120,1 24,4 81,6 115,1 26,9 79,4 109,8 29,9 77,2139,7 18,8 92,4 135,3 20,4 90,2 130,7 22,3 88,0 125,8 24,5 85,8 120,7 27,1 83,7 115,4 30,0 81,5127,0 20,2 93,7 123,8 22,1 91,6 119,8 24,3 89,4 115,2 26,9 87,2 109,8 29,8 85,1 103,6 33,2 82,9135,6 20,5 93,5 131,7 22,3 91,3 127,2 24,6 89,2 122,2 27,1 87,0 116,6 30,0 84,8 110,4 33,3 82,7137,7 20,6 95,9 133,7 22,4 93,7 129,1 24,6 91,5 124,0 27,2 89,4 118,4 30,1 87,2 112,2 33,4 85,0144,2 20,8 91,4 139,9 22,6 89,2 135,1 24,8 86,9 129,8 27,4 84,7 124,1 30,2 82,4 117,9 33,5 80,2148,6 20,9 94,8 144,1 22,8 92,5 139,2 24,9 90,2 133,8 27,5 87,8 128,1 30,3 85,5 121,8 33,5 83,2155,1 21,1 93,0 150,6 23,0 90,5 145,6 25,1 88,0 140,2 27,6 85,5 134,3 30,5 82,9 128,1 33,6 80,4138,6 23,0 101,2 133,9 25,0 98,4 129,0 27,5 95,6 123,8 30,3 92,7 118,3 33,6 89,9 112,6 37,2 87,1148,0 23,2 100,7 143,3 25,3 97,9 138,1 27,8 95,2 132,6 30,6 92,4 126,6 33,8 89,6 120,2 37,4 86,9150,4 23,3 103,2 145,6 25,4 100,5 140,4 27,9 97,7 134,8 30,7 95,0 128,7 33,9 92,3 122,2 37,5 89,5157,8 23,5 100,4 152,8 25,6 97,9 147,4 28,1 95,3 141,5 30,9 92,8 135,2 34,1 90,2 128,5 37,7 87,7162,8 23,6 106,1 157,6 25,7 103,7 152,1 28,2 101,3 146,1 31,1 98,9 139,7 34,3 96,6 132,9 37,8 94,2170,5 23,8 109,9 165,0 25,9 107,9 159,1 28,4 105,9 153,0 31,3 103,9 146,6 34,5 101,8 139,8 38,0 99,8152,4 22,6 113,2 147,9 24,9 110,6 143,0 27,5 108,0 137,5 30,6 105,4 131,4 34,2 102,8 124,9 38,3 100,2162,1 23,0 112,7 157,5 25,1 110,1 152,3 27,7 107,5 146,5 30,8 104,9 140,0 34,3 102,3 132,9 38,3 99,7164,6 23,0 115,7 160,0 25,2 113,1 154,7 27,8 110,5 148,8 30,9 107,9 142,2 34,4 105,4 135,0 38,3 102,8172,5 23,3 111,8 167,6 25,4 109,3 162,1 28,0 106,8 155,9 31,0 104,2 149,1 34,4 101,7 141,6 38,4 99,2177,9 23,5 117,6 172,9 25,6 115,1 167,2 28,1 112,6 160,8 31,1 110,1 153,8 34,5 107,6 146,2 38,4 105,1186,4 23,8 119,6 181,0 25,8 117,2 174,9 28,3 114,8 168,3 31,2 112,4 161,1 34,5 110,0 153,4 38,4 107,6172,9 27,0 127,8 168,3 29,6 124,7 162,7 32,7 121,6 156,4 36,3 118,5 149,2 40,5 115,4 141,2 45,1 112,3183,8 27,3 126,8 179,2 29,9 123,6 173,6 33,0 120,5 167,0 36,5 117,4 159,3 40,6 114,3 150,6 45,2 111,1186,6 27,4 130,0 182,0 30,0 126,9 176,4 33,0 123,8 169,7 36,6 120,6 161,9 40,7 117,5 153,0 45,2 114,4195,4 27,7 126,3 190,7 30,2 123,3 184,8 33,2 120,3 177,8 36,7 117,3 169,6 40,8 114,3 160,4 45,3 111,3201,5 27,9 133,5 196,6 30,4 130,6 190,5 33,3 127,7 183,2 36,8 124,8 174,9 40,9 122,0 165,4 45,4 119,1211,1 28,2 138,7 205,6 30,6 136,1 199,1 33,5 133,5 191,5 37,0 130,9 182,8 41,0 128,3 173,1 45,6 125,6198,9 31,0 147,6 193,5 33,8 144,2 187,2 37,2 140,7 180,0 41,3 137,2 172,0 46,0 133,8 163,0 51,4 130,3212,0 31,4 146,7 206,1 34,2 143,2 199,3 37,6 139,6 191,7 41,6 136,1 183,2 46,3 132,6 173,8 51,6 129,060470427 / 19,528 / 2130 / 2232 / 23,524 / 1726 / 1927 / 19,528 / 2130 / 2232 / 23,5215,3 31,6 150,5 209,3 34,3 147,0 202,4 37,7 143,4 194,7 41,7 139,9 186,1 46,3 136,4 176,7 51,6 132,8225,6 32,0 145,7 219,0 34,6 142,3 211,8 38,0 138,8 203,7 41,9 135,4 195,0 46,5 132,0 185,6 51,7 128,5232,7 32,3 153,4 225,7 34,9 150,1 218,1 38,2 146,7 209,9 42,1 143,4 201,2 46,6 140,1 191,8 51,7 136,8243,5 32,7 157,3 235,9 35,3 154,2 227,8 38,5 151,1 219,4 42,3 148,0 210,7 46,7 144,9 201,6 51,8 141,9224,9 35,9 165,4 218,6 39,1 161,0 211,3 42,9 156,7 202,9 47,5 152,3 193,5 52,8 148,0 183,1 58,7 143,6239,1 36,3 164,9 232,1 39,5 160,5 224,2 43,4 156,0 215,5 48,0 151,5 205,9 53,2 147,0 195,5 59,1 142,5242,8 36,4 169,3 235,6 39,6 164,8 227,6 43,5 160,3 218,8 48,1 155,8 209,2 53,3 151,4 198,8 59,2 146,9254,6 36,8 164,4 246,7 40,0 159,9 238,3 43,8 155,5 229,2 48,4 151,1 219,5 53,6 146,7 209,2 59,5 142,3262,9 37,1 173,4 254,5 40,2 169,1 245,7 44,1 164,8 236,4 48,6 160,5 226,7 53,8 156,2 216,5 59,7 151,9275,9 37,5 178,2 266,8 40,6 174,2 257,4 44,4 170,2 247,9 48,9 166,1 238,0 54,1 162,1 228,0 59,9 158,116Performance refers to operation at full re-circulationTa = input air temperature at treatment (°C)DB = dry bulbWB = wet bulbkWf = Cooling capacity in kWkWs = sensible cooling capacity (kW)kWe = Compressor power input in kWthe cooling capacities have not accounted for the heat dissipation of the centrifugal fan motors.

BT08L005GB-01PACKAGED362 - 904AIR FLOW: REDUCEDCOOLING PERFORMANCESizeTa(°C)DB/WBTEMPERATURE OF WATER LEAVING THE EXTERNAL HEAT EXCHANGER (°C) - TEMPERATURE DIFFERENTIAL 5°C25 30 35 40 45 50kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs80490424 / 1726 / 1927 / 19,528 / 2130 / 2232 / 23,524 / 1726 / 1927 / 19,528 / 2130 / 2232 / 23,5268,9 40,9 197,8 261,2 44,6 192,9 252,4 49,0 187,9 242,4 54,1 183,0 231,2 59,9 178,0 218,9 66,4 173,0286,6 41,4 197,0 278,6 45,1 191,9 269,1 49,5 186,8 258,2 54,6 181,7 245,8 60,4 176,6 232,0 66,8 171,5291,1 41,6 202,1 283,0 45,3 197,0 273,4 49,6 191,9 262,3 54,7 186,8 249,7 60,5 181,7 235,7 66,9 176,6304,8 42,0 195,8 296,4 45,7 190,7 286,5 50,0 185,7 275,0 55,1 180,6 262,0 60,8 175,6 247,5 67,2 170,5314,2 42,3 205,7 305,6 46,0 200,8 295,5 50,3 195,8 283,9 55,3 190,9 270,7 60,9 185,9 256,1 67,3 180,9328,5 42,8 209,6 319,6 46,4 204,9 309,3 50,7 200,2 297,6 55,6 195,5 284,5 61,2 190,8 270,1 67,4 186,0296,3 46,5 219,3 286,7 50,6 213,3 276,2 55,5 207,2 264,6 61,2 201,2 252,1 67,6 195,1 238,5 74,8 189,1315,5 47,0 219,7 305,6 51,2 213,5 294,7 56,1 207,3 282,5 61,8 201,1 269,1 68,2 194,9 254,6 75,4 188,7320,4 47,1 225,4 310,5 51,4 219,2 299,3 56,3 213,0 287,0 62,0 206,8 273,5 68,4 200,5 258,8 75,5 194,3335,6 47,6 217,1 325,1 51,8 210,9 313,5 56,8 204,7 300,7 62,5 198,4 286,9 68,8 192,2 272,1 75,9 186,0346,1 47,9 224,6 335,0 52,1 218,4 323,0 57,1 212,2 310,0 62,8 206,0 296,2 69,2 199,8 281,3 76,2 193,7362,3 48,3 219,6 350,1 52,6 213,6 337,4 57,6 207,5 324,2 63,3 201,4 310,3 69,7 195,3 295,9 76,7 189,2Performance refers to operation at full re-circulationTa = input air temperature at treatment (°C)DB = dry bulbWB = wet bulbkWf = Cooling capacity in kWkWs = sensible cooling capacity (kW)kWe = Compressor power input in kWthe cooling capacities have not accounted for the heat dissipation of the centrifugal fan motors.17

BT08L005GB-01PACKAGED362 - 904AIR FLOW: REDUCEDSize 362 402 452 464 524 604 704 804 904Air flow l/s 4444 4888 5333 6389 7222 8056 8889 10000 11111HEATING PERFORMANCETEMPERATURE OF WATER LEAVING THE EXTERNAL HEAT EXCHANGER (°C) - TEMPERATURE DIF-Size Ta (°C)6 8 10 12 14 16kWt kWe kWt kWe kWt kWe kWt kWe kWt kWe kWt kWe362402452464524101518192021251015181920212510151819202125101518192021251015181920125,4 20,5 131,7 21,1 137,9 21,7 144,2 22,4 150,5 23,1 156,9 23,8122,9 22,5 128,8 23,1 134,7 23,8 140,8 24,5 147,0 25,2 153,2 25,9121,3 23,8 127,0 24,4 132,9 25,1 138,8 25,8 145,0 26,5 151,2 27,3120,8 24,2 126,4 24,9 132,2 25,6 138,2 26,3 144,3 27,0 150,6 27,8120,3 24,7 125,9 25,3 131,6 26,0 137,6 26,8 143,7 27,5 149,9 28,3119,7 25,1 125,3 25,8 131,0 26,5 136,9 27,2 143,0 28,0 149,3 28,8117,5 27,1 122,9 27,8 128,6 28,5 134,5 29,3 140,6 30,1 147,0 30,9143,3 24,1 150,1 24,8 156,9 25,5 163,9 26,3 171,0 27,1 178,2 27,9140,2 26,4 146,7 27,1 153,2 27,9 159,9 28,7 166,7 29,5 173,6 30,3138,3 27,9 144,6 28,6 151,0 29,4 157,5 30,2 164,2 31,0 170,9 31,7137,6 28,4 143,9 29,1 150,3 29,9 156,8 30,7 163,3 31,5 170,0 32,2137,0 28,9 143,2 29,7 149,5 30,4 156,0 31,2 162,5 32,0 169,1 32,7136,3 29,4 142,5 30,2 148,8 31,0 155,2 31,7 161,6 32,5 168,2 33,2133,7 31,6 139,7 32,4 145,8 33,2 152,0 33,9 158,3 34,6 164,7 35,3157,7 27,4 165,1 28,3 172,7 29,1 180,4 30,1 188,2 31,0 196,1 32,0154,1 29,9 161,2 30,8 168,5 31,8 175,9 32,7 183,4 33,7 191,1 34,7151,9 31,6 158,9 32,5 165,9 33,4 173,2 34,4 180,6 35,4 188,1 36,4151,2 32,1 158,1 33,1 165,1 34,0 172,3 35,0 179,6 35,9 187,1 37,0150,5 32,7 157,3 33,6 164,3 34,6 171,4 35,5 178,7 36,5 186,2 37,5149,8 33,3 156,5 34,2 163,5 35,2 170,6 36,1 177,8 37,1 185,2 38,1147,0 35,7 153,5 36,6 160,2 37,6 167,1 38,5 174,2 39,5 181,4 40,5166,8 26,3 174,9 27,1 183,2 27,9 191,6 28,8 200,1 29,6 208,7 30,5164,1 29,2 171,6 30,0 179,4 30,8 187,3 31,6 195,4 32,4 203,7 33,3161,9 31,0 169,1 31,8 176,5 32,6 184,3 33,4 192,3 34,2 200,7 35,1161,1 31,6 168,1 32,4 175,5 33,2 183,2 34,0 191,3 34,9 199,7 35,7160,3 32,2 167,1 33,0 174,4 33,8 182,1 34,6 190,2 35,5 198,7 36,3159,4 32,9 166,1 33,6 173,3 34,4 181,0 35,3 189,1 36,1 197,8 37,0155,4 35,5 161,5 36,3 168,4 37,0 176,1 37,9 184,6 38,7 193,9 39,6192,5 31,9 201,7 32,8 211,0 33,7 220,4 34,7 229,9 35,7 239,5 36,7188,5 35,2 197,3 36,1 206,2 37,1 215,2 38,0 224,3 39,0 233,5 40,0186,0 37,3 194,5 38,3 203,2 39,2 212,0 40,2 220,9 41,1 229,9 42,1185,2 38,0 193,6 39,0 202,2 40,0 210,9 40,9 219,7 41,9 228,6 42,8184,3 38,8 192,7 39,8 201,2 40,7 209,8 41,7 218,5 42,6 227,4 43,6604212510151819202125183,4 39,6 191,7 40,5 200,2 41,5 208,7 42,4 217,4 43,4 226,2 44,3179,9 42,7 187,9 43,7 195,9 44,7 204,2 45,6 212,6 46,5 221,2 47,4216,4 34,7 226,5 35,6 236,8 36,6 247,5 37,7 258,5 38,8 269,8 39,9212,3 38,2 221,4 39,1 231,2 40,2 241,5 41,2 252,4 42,3 264,0 43,5209,8 40,5 219,2 41,6 229,0 42,6 239,2 43,7 249,7 44,8 260,7 45,9208,9 41,3 218,5 42,4 228,4 43,5 238,6 44,6 249,0 45,7 259,7 46,8208,1 42,2 218,0 43,3 228,0 44,4 238,1 45,5 248,4 46,6 258,7 47,6207,2 43,0 217,5 44,2 227,6 45,3 237,8 46,4 247,8 47,5 257,8 48,5203,7 46,6 216,0 48,1 227,3 49,4 237,4 50,5 246,3 51,4 254,2 52,1Performance refers to operation at full re-circulationTa = input air temperature at treatment (°C)DB = dry bulbkWt = Heating capacity (kW)kWe = Compressor power input in kWnot all thermal yields take into account the heat dissipated by the fan motors18

BT08L005GB-01PACKAGED362 - 904AIR FLOW: REDUCEDHEATING PERFORMANCETEMPERATURE OF WATER LEAVING THE EXTERNAL HEAT EXCHANGER (°C) - TEMPERATURE DIF-Size Ta (°C)6 8 10 12 14 16kWt kWe kWt kWe kWt kWe kWt kWe kWt kWe kWt kWe704804904101518192021251015181920212510151819202125250,2 41,8 262,1 43,1 274,2 44,4 286,5 45,7 298,9 47,1 311,4 48,6244,6 45,9 256,1 47,2 267,9 48,6 279,8 50,0 292,0 51,5 304,4 53,0241,3 48,5 252,5 49,9 264,1 51,3 275,9 52,8 288,0 54,3 300,5 55,9240,2 49,4 251,3 50,8 262,8 52,2 274,6 53,7 286,7 55,3 299,2 56,9239,1 50,3 250,1 51,7 261,5 53,2 273,3 54,7 285,5 56,3 298,0 57,9238,0 51,3 248,9 52,7 260,3 54,2 272,0 55,7 284,2 57,3 296,8 58,9233,6 55,3 244,1 56,8 255,3 58,3 267,0 59,9 279,3 61,5 292,2 63,2290,5 45,2 304,5 46,5 318,7 47,8 333,2 49,1 347,9 50,6 362,8 52,0284,5 49,8 298,0 51,0 312,3 52,2 327,6 53,3 343,8 54,4 360,9 55,5281,3 52,4 294,1 53,8 308,1 55,2 323,1 56,4 339,1 57,4 356,2 58,3280,2 53,2 292,9 54,8 306,6 56,2 321,4 57,5 337,2 58,5 354,0 59,4279,2 54,1 291,7 55,8 305,1 57,3 319,6 58,6 335,1 59,7 351,6 60,6278,2 54,9 290,4 56,8 303,6 58,4 317,7 59,8 332,8 60,9 348,8 61,8274,6 58,2 285,6 60,9 297,2 63,1 309,2 65,0 321,7 66,4 334,7 67,4321,2 51,1 336,7 52,6 352,5 54,1 368,5 55,7 384,8 57,3 401,4 59,0313,7 55,8 328,3 57,3 343,6 58,9 359,5 60,7 376,2 62,5 393,4 64,4309,3 58,9 323,6 60,4 338,6 62,1 354,0 63,8 370,0 65,6 386,5 67,5307,8 59,9 322,2 61,5 336,9 63,2 352,1 64,9 367,7 66,6 383,8 68,5306,3 61,0 320,7 62,6 335,3 64,3 350,2 66,0 365,4 67,7 380,9 69,4304,9 62,1 319,3 63,8 333,8 65,4 348,4 67,0 363,0 68,7 377,8 70,4299,1 66,8 313,9 68,5 327,7 70,1 340,7 71,5 352,7 72,8 363,8 74,0Performance refers to operation at full re-circulationTa = input air temperature at treatment (°C)DB = dry bulbkWt = Heating capacity (kW)kWe = Compressor power input in kWnot all thermal yields take into account the heat dissipated by the fan motors19

BT08L005GB-01PACKAGED362 - 904AIR FLOW: HIGHSize 362 402 452 464 524 604 704 804 904Air flow l/s 6666 7222 7500 9722 10833 11667 12222 14722 15556COOLING PERFORMANCESizeTa(°C)DB/WBTEMPERATURE OF WATER LEAVING THE EXTERNAL HEAT EXCHANGER (°C) - TEMPERATURE DIFFERENTIAL 5°C25 30 35 40 45 50kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs36240245246452416 / 1220 / 1424 / 1726 / 1927 / 19,528 / 2116 / 1220 / 1424 / 1726 / 1927 / 19,528 / 2116 / 1220 / 1424 / 1726 / 1927 / 19,528 / 2116 / 1220 / 1424 / 1726 / 1927 / 19,528 / 2116 / 1220 / 1424 / 1726 / 1927 / 19,528 / 2116 / 1220 / 14106,8 17,8 81,2 103,0 19,4 79,3 98,9 21,3 77,5 94,5 23,6 75,6 89,7 26,2 73,7 84,6 29,1 71,9113,8 18,0 93,5 109,7 19,6 91,6 105,4 21,5 89,7 100,6 23,8 87,9 95,5 26,4 86,0 90,1 29,3 84,1124,9 18,3 100,0 120,6 19,9 98,0 115,8 21,8 95,9 110,7 24,1 93,8 105,2 26,7 91,7 99,4 29,6 89,7132,8 18,6 99,4 128,2 20,1 97,0 123,3 22,0 94,7 118,0 24,3 92,4 112,4 26,9 90,1 106,3 29,8 87,8134,8 18,6 102,2 130,2 20,2 99,8 125,3 22,1 97,4 119,9 24,3 95,0 114,2 26,9 92,6 108,1 29,9 90,2141,0 18,8 97,4 136,3 20,4 94,7 131,3 22,3 92,1 125,9 24,5 89,4 120,0 27,1 86,7 113,8 30,0 84,1118,4 20,0 88,0 114,6 21,8 85,6 110,3 24,1 83,1 105,6 26,6 80,7 100,3 29,6 78,3 94,6 32,9 75,9126,2 20,2 104,2 122,3 22,1 101,9 117,8 24,3 99,7 112,6 26,8 97,5 106,9 29,8 95,3 100,6 33,0 93,0138,5 20,6 109,1 134,3 22,4 106,8 129,4 24,6 104,6 123,8 27,1 102,3 117,6 30,0 100,1 110,6 33,3 97,9147,0 20,8 109,7 142,6 22,7 107,3 137,5 24,8 104,8 131,7 27,3 102,4 125,2 30,2 99,9 118,0 33,4 97,4149,2 20,9 114,2 144,7 22,7 111,7 139,6 24,9 109,1 133,7 27,4 106,6 127,2 30,2 104,1 120,0 33,4 101,5155,8 21,1 114,8 151,2 22,9 112,0 145,8 25,1 109,2 139,9 27,6 106,4 133,3 30,4 103,5 126,0 33,6 100,7128,2 22,7 95,1 123,7 24,7 92,8 118,8 27,1 90,4 113,6 29,9 88,0 107,9 33,2 85,6 101,9 36,8 83,2136,8 22,9 110,4 132,1 24,9 107,7 127,0 27,4 105,0 121,4 30,2 102,2 115,3 33,4 99,5 108,7 37,0 96,8150,5 23,3 116,9 145,4 25,3 114,3 139,8 27,8 111,6 133,7 30,6 108,9 127,0 33,8 106,2 119,7 37,3 103,5160,1 23,6 116,0 154,7 25,6 113,8 148,7 28,1 111,5 142,3 30,9 109,2 135,2 34,1 107,0 127,7 37,6 104,7162,6 23,6 119,5 157,1 25,7 117,4 151,0 28,1 115,2 144,5 31,0 113,1 137,4 34,1 111,0 129,8 37,7 108,9170,2 23,8 115,2 164,3 25,9 113,6 158,0 28,4 112,1 151,2 31,2 110,5 143,9 34,4 109,0 136,1 37,9 107,4141,9 22,3 109,1 137,4 24,6 106,4 132,2 27,3 103,7 126,4 30,4 101,0 120,0 34,0 98,2 113,0 38,1 95,5151,0 22,6 127,5 146,2 24,8 125,0 140,9 27,4 122,6 134,9 30,6 120,2 128,4 34,2 117,8 121,2 38,2 115,3165,5 23,1 135,6 160,3 25,2 133,2 154,6 27,8 130,9 148,3 30,8 128,6 141,4 34,4 126,3 133,9 38,3 123,9175,8 23,4 134,4 170,3 25,5 132,0 164,2 28,0 129,5 157,6 31,0 127,0 150,4 34,5 124,6 142,7 38,4 122,1178,5 23,5 138,6 172,9 25,6 136,1 166,7 28,1 133,6 160,0 31,1 131,0 152,8 34,5 128,5 144,9 38,4 126,0186,6 23,8 133,0 180,7 25,8 130,2 174,3 28,3 127,4 167,3 31,2 124,6 159,8 34,6 121,8 151,7 38,4 119,0161,1 26,6 123,2 155,9 29,3 119,1 150,0 32,5 114,9 143,4 36,1 110,8 136,2 40,3 106,7 128,3 44,9 102,5171,5 26,9 142,7 166,1 29,5 139,3 159,9 32,7 135,9 153,0 36,3 132,4 145,3 40,4 129,0 136,9 45,1 125,6187,9 27,4 151,6 182,2 30,0 148,7 175,6 33,0 145,8 168,2 36,6 143,0 160,0 40,7 140,1 151,0 45,2 137,3199,4 27,8 150,5 193,4 30,3 147,7 186,6 33,3 144,9 178,9 36,8 142,1 170,4 40,8 139,3 161,0 45,3 136,5202,4 27,9 155,4 196,3 30,4 152,6 189,4 33,3 149,7 181,7 36,8 146,9 173,0 40,8 144,1 163,5 45,3 141,3211,4 28,3 149,4 205,2 30,7 146,4 198,1 33,6 143,4 190,1 37,0 140,4 181,3 40,9 137,4 171,5 45,3 134,4184,6 30,4 139,3 178,8 33,3 136,4 172,2 36,9 133,6 164,8 41,0 130,7 156,5 45,7 127,8 147,5 51,0 124,9195,9 30,8 162,4 190,1 33,7 159,5 183,2 37,2 156,5 175,4 41,3 153,5 166,6 46,0 150,5 156,9 51,3 147,560470424 / 1726 / 1927 / 19,528 / 2116 / 1220 / 1424 / 1726 / 1927 / 19,528 / 21214,4 31,5 172,6 208,0 34,3 169,5 200,7 37,6 166,4 192,4 41,7 163,3 183,1 46,4 160,1 172,9 51,7 157,0227,6 32,0 172,2 220,7 34,7 169,0 213,0 38,0 165,7 204,4 41,9 162,5 195,0 46,5 159,3 184,8 51,8 156,0231,0 32,2 178,1 224,0 34,8 174,9 216,1 38,1 171,6 207,5 42,0 168,4 198,1 46,6 165,1 188,0 51,8 161,8241,6 32,6 172,9 234,0 35,2 169,6 225,8 38,4 166,2 217,0 42,2 162,9 207,7 46,7 159,6 197,8 51,8 156,2206,8 35,3 160,5 199,7 38,6 156,9 192,0 42,5 153,2 183,6 47,0 149,5 174,5 52,2 145,8 164,8 58,0 142,1219,6 35,7 178,6 212,6 38,9 174,5 204,7 42,8 170,5 195,8 47,4 166,4 185,9 52,6 162,3 175,2 58,5 158,2241,0 36,4 189,3 233,6 39,5 184,8 225,0 43,4 180,4 215,4 47,9 175,9 204,8 53,2 171,5 193,1 59,1 167,1256,7 36,8 188,9 248,6 40,0 184,4 239,5 43,8 179,8 229,4 48,3 175,3 218,5 53,5 170,8 206,5 59,5 166,2260,8 37,0 194,7 252,4 40,1 190,2 243,2 43,9 185,6 233,1 48,4 181,1 222,0 53,6 176,5 210,1 59,6 172,0273,5 37,4 187,0 264,4 40,5 182,5 254,6 44,3 178,0 244,2 48,7 173,4 233,0 53,9 168,9 221,2 59,8 164,420Performance refers to operation at full re-circulationTa = input air temperature at treatment (°C)DB = dry bulbWB = wet bulbkWf = Cooling capacity in kWkWs = sensible cooling capacity (kW)kWe = Compressor power input in kWthe cooling capacities have not accounted for the heat dissipation of the centrifugal fan motors.

BT08L005GB-01PACKAGED362 - 904AIR FLOW: HIGHCOOLING PERFORMANCESizeTa(°C)DB/WBTEMPERATURE OF WATER LEAVING THE EXTERNAL HEAT EXCHANGER (°C) - TEMPERATURE DIFFERENTIAL 5°C25 30 35 40 45 50kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs kWf kWe kWs80490416 / 1220 / 1424 / 1726 / 1927 / 19,528 / 2116 / 1220 / 1424 / 1726 / 1927 / 19,528 / 21250,0 40,3 179,2 241,3 44,1 173,4 231,8 48,5 167,6 221,5 53,6 161,9 210,3 59,4 156,1 198,4 65,9 150,3266,4 40,8 219,8 257,2 44,5 214,7 247,2 48,9 209,5 236,2 54,0 204,3 224,4 59,8 199,1 211,7 66,3 193,9292,5 41,5 235,3 282,5 45,3 230,6 271,5 49,7 225,9 259,7 54,7 221,2 247,0 60,4 216,5 233,5 66,8 211,8310,9 42,1 232,8 300,2 45,8 228,2 288,6 50,2 223,6 276,2 55,1 218,9 263,1 60,8 214,3 249,1 67,0 209,7315,7 42,3 240,1 304,7 46,0 235,5 293,0 50,3 230,8 280,5 55,3 226,2 267,2 60,8 221,5 253,1 67,1 216,9330,1 42,7 231,7 318,6 46,4 227,0 306,4 50,7 222,2 293,5 55,6 217,4 279,9 61,1 212,6 265,6 67,2 207,8273,8 45,8 208,0 263,5 49,9 202,4 252,5 54,8 196,8 240,8 60,4 191,2 228,4 66,8 185,6 215,2 73,9 180,0291,0 46,3 237,9 280,7 50,4 232,1 269,6 55,3 226,4 257,5 60,9 220,6 244,6 67,2 214,9 230,8 74,3 209,2319,2 47,1 254,3 308,5 51,2 248,3 296,6 56,1 242,4 283,6 61,8 236,4 269,4 68,1 230,4 254,1 75,2 224,5339,7 47,6 253,8 328,3 51,8 247,7 315,6 56,7 241,6 301,6 62,4 235,4 286,3 68,8 229,3 269,6 75,9 223,1345,0 47,8 261,7 333,4 52,0 255,5 320,5 56,9 249,3 306,2 62,6 243,1 290,5 68,9 236,9 273,5 76,1 230,8361,5 48,2 251,3 349,2 52,4 245,0 335,4 57,4 238,6 320,1 63,1 232,3 303,3 69,5 226,0 285,1 76,7 219,6Performance refers to operation at full re-circulationTa = input air temperature at treatment (°C)DB = dry bulbWB = wet bulbkWf = Cooling capacity in kWkWs = sensible cooling capacity (kW)kWe = Compressor power input in kWthe cooling capacities have not accounted for the heat dissipation of the centrifugal fan motors.21

BT08L005GB-01PACKAGED362 - 904AIR FLOW: HIGHSize 362 402 452 464 524 604 704 804 904Air flow l/s 6666 7222 7500 9722 10833 11667 12222 14722 15556HEATING PERFORMANCETEMPERATURE OF WATER LEAVING THE EXTERNAL HEAT EXCHANGER (°C) - TEMPERATURE DIF-Size Ta (°C)6 8 10 12 14 16kWt kWe kWt kWe kWt kWe kWt kWe kWt kWe kWt kWe3624024524645241015181920212510151819202125101518192021251015181920212510151819202125130,2 18,3 136,8 18,8 143,4 19,2 150,2 19,7 157,1 20,2 164,2 20,7128,6 20,0 134,1 20,4 140,0 20,9 146,3 21,4 153,0 21,9 160,0 22,5127,1 21,2 132,3 21,6 138,0 22,1 144,1 22,6 150,6 23,1 157,6 23,7126,5 21,5 131,7 22,0 137,3 22,5 143,4 23,0 149,9 23,5 156,9 24,1125,9 21,9 131,1 22,4 136,7 22,9 142,7 23,4 149,2 23,9 156,1 24,5125,3 22,4 130,5 22,8 136,0 23,3 142,0 23,8 148,5 24,4 155,3 25,0122,3 24,1 127,8 24,6 133,5 25,1 139,5 25,7 145,8 26,2 152,3 26,8147,8 21,3 155,1 21,9 162,6 22,5 170,2 23,1 178,0 23,7 186,1 24,4144,7 23,3 151,7 23,9 158,9 24,5 166,3 25,1 173,8 25,8 181,5 26,4142,8 24,6 149,7 25,2 156,7 25,9 163,9 26,5 171,2 27,1 178,7 27,8142,2 25,1 149,0 25,7 156,0 26,3 163,1 26,9 170,3 27,6 177,7 28,2141,6 25,6 148,3 26,2 155,2 26,8 162,3 27,4 169,5 28,1 176,8 28,7140,9 26,1 147,6 26,7 154,5 27,3 161,5 27,9 168,6 28,6 175,8 29,2138,4 28,1 144,9 28,7 151,4 29,3 158,2 30,0 165,0 30,6 172,0 31,2162,6 24,7 170,7 25,3 178,9 26,0 187,2 26,7 195,6 27,5 204,1 28,3158,9 26,9 166,6 27,6 174,5 28,3 182,5 29,1 190,6 29,9 198,9 30,7156,6 28,4 164,1 29,1 171,8 29,9 179,6 30,6 187,6 31,4 195,7 32,3155,9 28,9 163,3 29,6 170,9 30,4 178,7 31,2 186,6 32,0 194,7 32,8155,1 29,4 162,5 30,1 170,0 30,9 177,7 31,7 185,6 32,5 193,7 33,4154,4 29,9 161,7 30,7 169,2 31,5 176,8 32,3 184,6 33,1 192,6 33,9151,5 32,2 158,4 33,0 165,6 33,8 173,0 34,6 180,7 35,4 188,5 36,2172,1 23,3 180,5 23,9 189,2 24,5 198,2 25,1 207,5 25,8 217,0 26,5168,1 25,6 176,6 26,2 185,3 26,8 194,1 27,5 203,1 28,2 212,1 28,9165,7 27,1 174,3 27,8 182,9 28,4 191,6 29,1 200,3 29,7 209,0 30,4164,9 27,7 173,5 28,3 182,1 29,0 190,7 29,6 199,3 30,3 208,0 31,0164,2 28,2 172,7 28,9 181,3 29,6 189,8 30,2 198,4 30,9 206,9 31,5163,4 28,8 172,0 29,5 180,5 30,1 189,0 30,8 197,4 31,5 205,8 32,1160,4 31,3 168,8 32,0 177,2 32,7 185,4 33,3 193,4 33,9 201,4 34,6197,9 28,2 207,7 28,9 217,8 29,6 228,1 30,4 238,7 31,1 249,4 32,0194,1 31,0 203,6 31,7 213,3 32,4 223,1 33,2 233,1 34,0 243,3 34,8191,7 32,8 201,0 33,6 210,4 34,3 220,0 35,1 229,8 35,8 239,7 36,6190,9 33,5 200,1 34,2 209,5 35,0 219,0 35,7 228,7 36,5 238,5 37,3190,1 34,2 199,2 34,9 208,5 35,7 218,0 36,4 227,6 37,2 237,4 37,9189,4 34,9 198,4 35,6 207,5 36,3 216,9 37,1 226,5 37,9 236,2 38,6186,1 37,8 194,7 38,5 203,6 39,3 212,7 40,0 222,1 40,8 231,7 41,51015222,8 31,2 233,8 32,0 245,1 32,8 256,5 33,6 268,2 34,5 280,0 35,4218,7 34,2 229,3 35,0 240,1 35,8 251,0 36,6 262,2 37,5 273,6 38,46041819202125Performance refers to operation at full re-circulationTa = input air temperature at treatment (°C)DB = dry bulbkWt = Heating capacity (kW)kWe = Compressor power input in kWnot all thermal yields take into account the heat dissipated by the fan motors216,3 36,2 226,6 37,0 237,1 37,8 247,8 38,7 258,7 39,5 269,9 40,4215,5 36,9 225,7 37,7 236,1 38,6 246,7 39,4 257,6 40,3 268,7 41,1214,7 37,7 224,8 38,5 235,1 39,3 245,6 40,1 256,4 41,0 267,5 41,9213,8 38,4 223,8 39,2 234,1 40,1 244,6 40,9 255,3 41,8 266,3 42,6210,6 41,7 220,2 42,5 230,1 43,4 240,3 44,2 250,9 45,0 261,7 45,922

BT08L005GB-01PACKAGED362 - 904AIR FLOW: HIGHHEATING PERFORMANCETEMPERATURE OF WATER LEAVING THE EXTERNAL HEAT EXCHANGER (°C) - TEMPERATURE DIF-Size Ta (°C)6 8 10 12 14 16kWt kWe kWt kWe kWt kWe kWt kWe kWt kWe kWt kWe704804904101518192021251015181920212510151819202125256,9 38,0 269,6 39,0 282,5 40,0 295,6 41,1 308,9 42,2 322,4 43,3251,1 41,5 263,4 42,5 275,9 43,6 288,6 44,8 301,6 45,9 314,7 47,1247,8 43,8 259,7 44,9 271,9 46,1 284,3 47,2 297,1 48,4 310,1 49,7246,6 44,7 258,4 45,8 270,5 46,9 282,9 48,1 295,6 49,3 308,6 50,6245,5 45,5 257,2 46,6 269,1 47,8 281,5 49,0 294,1 50,2 307,1 51,5244,4 46,4 255,9 47,5 267,8 48,7 280,0 49,9 292,6 51,1 305,5 52,4240,0 50,1 250,9 51,3 262,3 52,4 274,2 53,7 286,5 55,0 299,3 56,4301,5 40,7 316,4 41,6 331,7 42,6 347,5 43,7 363,8 44,8 380,6 46,0296,8 44,4 310,0 45,4 324,0 46,4 338,9 47,5 354,6 48,6 371,1 49,9293,0 46,9 305,9 47,9 319,5 48,9 334,0 50,0 349,4 51,2 365,5 52,4291,6 47,8 304,5 48,8 318,1 49,8 332,5 50,9 347,7 52,1 363,6 53,3290,2 48,7 303,0 49,7 316,6 50,7 331,0 51,8 346,0 53,0 361,8 54,2288,7 49,6 301,6 50,6 315,2 51,6 329,5 52,8 344,4 53,9 359,9 55,2281,8 53,4 295,6 54,5 309,6 55,6 323,8 56,7 338,1 57,9 352,6 59,1333,0 46,7 349,6 47,8 366,6 49,0 384,1 50,2 402,0 51,5 420,3 52,8324,9 50,8 341,0 52,0 357,5 53,2 374,4 54,6 391,6 56,0 409,2 57,4320,5 53,5 336,1 54,8 352,1 56,1 368,5 57,5 385,3 58,9 402,6 60,4319,1 54,5 334,4 55,8 350,3 57,1 366,5 58,5 383,2 59,9 400,4 61,4317,7 55,5 332,8 56,8 348,5 58,1 364,6 59,5 381,1 60,9 398,2 62,4316,3 56,5 331,2 57,8 346,7 59,1 362,6 60,5 379,0 62,0 396,0 63,5311,2 60,9 325,1 62,2 339,6 63,5 354,8 65,0 370,6 66,4 387,2 67,9Performance refers to operation at full re-circulationTa = input air temperature at treatment (°C)DB = dry bulbkWt = Heating capacity (kW)kWe = Compressor power input in kWnot all thermal yields take into account the heat dissipated by the fan motors23

BT08L005GB-01362402452464524604704804904PACKAGED362 - 904PERFORMANCES OF SUPPLY AIR FANSAIR FLOW: STANDARDEXTERNAL STATIC PRESSURE (Pa) 120 150 180 210 240 270 300 330 360 390 420 450 510 570Air flow l/s 5555 5555 5555 5555 5555 5555 5555 5555 5555 5555 5555 5555 5555 5555Fan RPM rpm 718 742 766 790 814 837 860 883 905 927 949 971 1013 1054Motor shaft input power kW 4.96 5.22 5.48 5.75 6.02 6.29 6.57 6.85 7.14 7.42 7.71 8.01 8.6 9.2Sound pressure level dB 86 87 87 87 87 88 88 88 88 89 89 89 90 91F.L.I. - Single Inlet fan kW 7.5 7.5 7.5 7.5 7.5 7.5 7.5 9 9 9 9 9 11 11F.L.A. - Single Inlet fan A 14.9 14.9 14.9 14.9 14.9 14.9 14.9 19.0 19.0 19.0 19.0 19.0 21.0 21.0Transmission code (fan) PF 2A 250 PF 2A 224PF 2A 236Transmission code (motor) PV 2A 156 PV 2A 177Air flow l/s 6111 6111 6111 6111 6111 6111 6111 6111 6111 6111 6111 6111 6111 6111Fan RPM rpm 767 790 812 834 856 878 899 920 941 962 982 1003 1042 1081Motor shaft input power kW 6.32 6.6 6.88 7.17 7.46 7.76 8.06 8.36 8.67 8.97 9.28 9.6 10.24 10.9Sound pressure level dB 88 89 89 89 89 89 89 90 90 90 91 91 91 92F.L.I. - Single Inlet fan kW 7.5 7.5 7.5 7.5 9 9 9 9 11 11 11 11 11 11F.L.A. - Single Inlet fan A 14.9 14.9 14.9 14.9 19.0 19.0 19.0 19.0 21.0 21.0 21.0 21.0 21.0 21.0Transmission code (fan) PF 2A 250 PF 2A 236PF 2A 224Transmission code (motor) PV 2A 156 PV 2A 177Air flow l/s 6666 6666 6666 6666 6666 6666 6666 6666 6666 6666 6666 6666 6666 6666Fan RPM rpm 820 841 862 882 902 922 942 962 982 1001 1020 1040 1077 1114Motor shaft input power kW 7.95 8.26 8.56 8.87 9.19 9.51 9.83 10.15 10.48 10.81 11.14 11.47 11.65 12.3Sound pressure level dB 90 90 90 91 91 91 91 91 92 92 92 92 93 93F.L.I. - Single Inlet fan kW 9 9 9 9 11 11 11 11 11 11 15 15 15 15F.L.A. - Single Inlet fan A 19.0 19.0 19.0 19.0 21.0 21.0 21.0 21.0 21.0 21.0 28.5 28.5 28.5 28.5Transmission code (fan) PF 2A 280 PF 2A 250PF 2A 315Transmission code (motor) PV 2A 177 PV 2A 177Air flow l/s 8056 8056 8056 8056 8056 8056 8056 8056 8056 8056 8056 8056 8056 8056Fan RPM rpm 680 705 730 756 781 806 831 856 881 905 930 954 1002 1049Motor shaft input power kW 6.9 7.3 7.7 8.2 8.6 9.1 9.5 10 10.5 11.1 11.6 12.2 12.7 13.8Sound pressure level dB 86 86 86 87 87 88 88 89 89 90 90 91 92 93F.L.I. - Single Inlet fan kW 9 9 9 9 9 11 11 11 11 15 15 15 15 15F.L.A. - Single Inlet fan A 19.0 19.0 19.0 19.0 19.0 21.0 21.0 21.0 21.0 28.5 28.5 28.5 28.5 28.5Transmission code (fan) PF 2A 315 PF 2A 315PF 3A 300Transmission code (motor) PV 2A 177 PV 2A 177Air flow l/s 9028 9028 9028 9028 9028 9028 9028 9028 9028 9028 9028 9028 9028 9028Fan RPM rpm 731 754 776 799 821 844 866 889 911 934 956 978 1022 1065Motor shaft input power kW 9.1 9.5 10 10.4 10.9 11.4 11.9 12.2 12.4 12.9 13.4 13.9 15.1 16.2Sound pressure level dB 88 88 89 89 89 89 90 90 91 91 92 92 93 93F.L.I. - Single Inlet fan kW 11 11 11 11 15 15 15 15 15 15 15 15 18.5 18.5F.L.A. - Single Inlet fan A 21.0 21.0 21.0 21.0 28.5 28.5 28.5 28.5 28.5 28.5 28.5 28.5 35.0 35.0Transmission code (fan) PF 2A 300PF 3A 300 PF 3A 280Transmission code (motor) PV 2A 177 PF 3A 170 PF 3A 180 PF 3A 190 PF 3A 200Air flow l/s 10000 10000 10000 10000 10000 10000 10000 10000 10000 10000 10000 10000 10000 10000Fan RPM rpm 792 812 833 853 873 894 914 935 955 975 995 1016 1056 -Motor shaft input power kW 11.9 12.1 12.3 12.8 13.3 13.7 14.2 14.8 15.3 15.8 16.4 16.9 18.1 -Sound pressure level dB 90 90 91 91 91 91 92 92 92 93 93 93 94 -F.L.I. - Single Inlet fan kW 15 15 15 15 15 15 15 15 18.5 18.5 18.5 18.5 18.5 -F.L.A. - Single Inlet fan A 28.5 28.5 28.5 28.5 28.5 28.5 28.5 28.5 35.0 35.0 35.0 35.0 35.0 -Transmission code (fan) PF 3A 315 PF 3A 300 PF 3A 280 -Transmission code (motor) PF 3A 170 PF 3A 180 PF 3A 190 PF 3A 200-Air flow l/s 11111 11111 11111 11111 11111 11111 11111 11111 11111 11111 11111 11111 11111 11111Fan RPM rpm 855 873 891 910 928 946 965 983 1001 1020 1038 1056 1093 1129Motor shaft input power kW 14.9 15.4 15.9 16.4 16.9 17.4 18 18.5 19 19.6 20.2 20.8 21.9 23.2Sound pressure level dB 93 93 93 93 93 94 94 94 94 94 94 95 95 96F.L.I. - Single Inlet fan kW 18.5 18.5 18.5 18.5 18.5 18.5 18.5 22 22 22 22 22 30 30F.L.A. - Single Inlet fan A 35.0 35.0 35.0 35.0 35.0 35.0 35.0 41.0 41.0 41.0 41.0 41.0 57.0 57.0Transmission code (fan) PF 3A 300 PF 3A 280 PF 3A 300 PF 3A 280PF 3A 300 PF 3A 280Transmission code (motor) PF 3A 170 PF 3A 180 PF 3A 200 PF A3 224Air flow l/s 12500 12500 12500 12500 12500 12500 12500 12500 12500 12500 12500 12500 12500 12500Fan RPM rpm 742 761 780 798 816 835 853 871 889 907 925 943 978 1012Motor shaft input power kW 14.2 14.7 15.2 15.8 16.4 16.9 17.5 18.1 18.7 19.3 20 20.6 21.9 23.2Sound pressure level dB 90 90 91 91 91 91 92 92 92 92 92 93 93 94F.L.I. - Single Inlet fan kW 18.5 18.5 18.5 18.5 18.5 18.5 18.5 18.5 22 22 22 22 30 30F.L.A. - Single Inlet fan A 35.0 35.0 35.0 35.0 35.0 35.0 35.0 35.0 41.0 41.0 41.0 41.0 57.0 57.0Transmission code (fan) PF 3A 355 PF 3A 315 PF 3A 300 PF 5A 315Transmission code (motor) PF 3A 180 PF 3A 190 PF 3A 180 PF 3A 190 PF 5A 224Air flow l/s 13889 13889 13889 13889 13889 13889 13889 13889 13889 13889 13889 13889 13889 13889Fan RPM rpm 794 811 828 845 862 878 895 911 928 944 961 977 1009 1041Motor shaft input power kW 18.3 18.9 19.5 20.1 20.7 21.3 21.9 22.5 23.2 23.8 24.5 25.2 26.5 27.9Sound pressure level dB 93 93 93 93 93 93 93 94 94 94 94 94 95 95F.L.I. - Single Inlet fan kW 22 22 22 22 22 22 30 30 30 30 30 30 30 30F.L.A. - Single Inlet fan A 41.0 41.0 41.0 41.0 41.0 41.0 57.0 57.0 57.0 57.0 57.0 57.0 57.0 57.0Transmission code (fan) PF 3A 355 PF 3A 315 PF 5A 355 PF 5A 315Transmission code (motor) PF 3A 200 PF 3A 190 PF 5A 224 PF 5A 200 PF 5A 224The performance takes into account the pressure drops in the unit (pressure drops in treatment coil, standard filters, etc.).To determine the performance required of the fans, you must add to the usable static pressure desired the pressure drops of any accessories.The value of absorbed electrical power has already been corrected by a factor that takes into account the losses in transmission and a minimum tolerance on the number of revs of the fan.24