INSTITUTUL NAÅ¢IONAL DE CERCETARE-DEZVOLTARE - ICECHIM

INSTITUTUL NAÅ¢IONAL DE CERCETARE-DEZVOLTARE - ICECHIM

INSTITUTUL NAÅ¢IONAL DE CERCETARE-DEZVOLTARE - ICECHIM

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

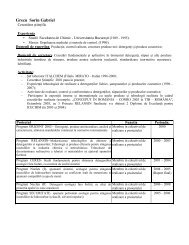

1 Bioresources and biomaterials - O<strong>DE</strong>VELOPMENT OF A PROCESS FOR ENZYMATIC PROTEIN HYDROLYSATESFROM GREEN ALGA <strong>DE</strong>SMO<strong>DE</strong>SMUS COMMUNISSanda VELEA, Lucia ILIE, Simona GHIMIS, Silvia TUDORACHE, Elena RADUThe National Institute for Research & Development in Chemistry and Petrochemistry, 202Splaiul Independentei, 060021 Bucharest, RomaniaProteins are the most abundant component in the algal biomass, representing more than 40%of the total dry weight, whereas lipids can be found as 20 to 30% of the biomass dependingon which strain is used. Therefore the production of large amounts of lipids from microalgaeinvolves the production of a large deal of protein, which can in fact be expected to double theamount of lipids produced. So, it is clear that the protein production must be valorised tomake the process economically positive.Extraction of added-value protein fractions from algal biomass for techno-functionalapplications in feeds, soil enhancers or as a source of nutrients for the cultivation of microalgein mixotrophic culture, can considerably increase the commercial value of microalgalbiomass.This paper focuses on the development of a process for enzymatic hydrolysis of cell proteinsin green microalga Desmodesmus communis. Enzymatic hydrolysis is selected insteadchemical hydrolysis to produce a high quality product, rich in essential amino acids, free oftoxic degradation products because the process is carried out under mild conditionsThe influence of reaction parameters on hydrolysis of extracted biomass with differentproteases such as Alcalase 2.5L, Flavorzyme 1000L and Savinase 8.0T was considered, bothalone or as a cocktail of enzymes. Significant changes in the degree of hydrolysis (from 30%until more than 70%), were observed which varied by using up to 4% (w/w) units of enzymeon suspension of the treated algae (20%).The process enlarges the portfolio of products that can be obtained from microalgal biomassand it is a new possibility to enhance the economic viability of microalgae based biofuelsproduction processes.