R TraceTek Leak Detection Product Selection Guide for Water

R TraceTek Leak Detection Product Selection Guide for Water

R TraceTek Leak Detection Product Selection Guide for Water

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

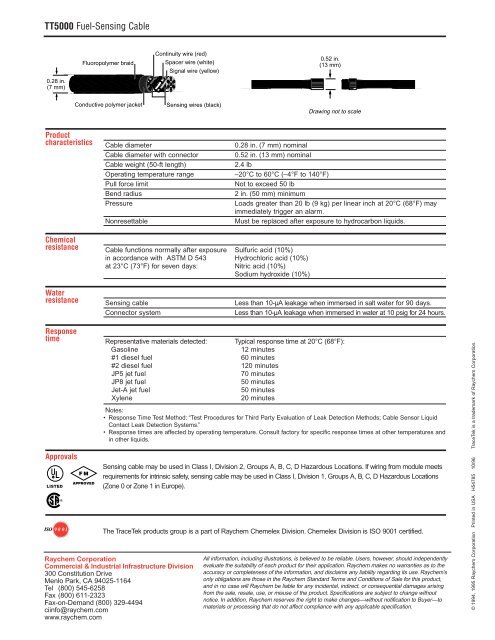

RTT5000 Fuel-Sensing Cable0.28 in.(7 mm)Fluoropolymer braidContinuity wire (red)Spacer wire (white)Signal wire (yellow)0.52 in.(13 mm)Conductive polymer jacketSensing wires (black)Drawing not to scale<strong>Product</strong>characteristics Cable diameter 0.28 in. (7 mm) nominalCable diameter with connector0.52 in. (13 mm) nominalCable weight (50-ft length)2.4 lbOperating temperature range–20°C to 60°C (–4°F to 140°F)Pull <strong>for</strong>ce limitNot to exceed 50 lbBend radius2 in. (50 mm) minimumPressureLoads greater than 20 lb (9 kg) per linear inch at 20°C (68°F) mayimmediately trigger an alarm.NonresettableMust be replaced after exposure to hydrocarbon liquids.Chemicalresistance Cable functions normally after exposure Sulfuric acid (10%)in accordance with ASTM D 543 Hydrochloric acid (10%)at 23°C (73°F) <strong>for</strong> seven days: Nitric acid (10%)Sodium hydroxide (10%)<strong>Water</strong>resistance Sensing cable Less than 10-µA leakage when immersed in salt water <strong>for</strong> 90 days.Connector systemLess than 10-µA leakage when immersed in water at 10 psig <strong>for</strong> 24 hours.Responsetime Representative materials detected: Typical response time at 20°C (68°F):Gasoline12 minutes#1 diesel fuel 60 minutes#2 diesel fuel 120 minutesJP5 jet fuel70 minutesJP8 jet fuel50 minutesJet-A jet fuel50 minutesXylene20 minutesApprovalsLISTED®ISO 9001F MAPPROVEDNotes:• Response Time Test Method: “Test Procedures <strong>for</strong> Third Party Evaluation of <strong>Leak</strong> <strong>Detection</strong> Methods; Cable Sensor LiquidContact <strong>Leak</strong> <strong>Detection</strong> Systems.”• Response times are affected by operating temperature. Consult factory <strong>for</strong> specific response times at other temperatures andin other liquids.Sensing cable may be used in Class I, Division 2, Groups A, B, C, D Hazardous Locations. If wiring from module meetsrequirements <strong>for</strong> intrinsic safety, sensing cable may be used in Class I, Division 1, Groups A, B, C, D Hazardous Locations(Zone 0 or Zone 1 in Europe).The <strong>TraceTek</strong> products group is a part of Raychem Chemelex Division. Chemelex Division is ISO 9001 certified.Raychem CorporationCommercial & Industrial Infrastructure Division300 Constitution DriveMenlo Park, CA 94025-1164Tel (800) 545-6258Fax (800) 611-2323Fax-on-Demand (800) 329-4494ciinfo@raychem.comwww.raychem.comAll in<strong>for</strong>mation, including illustrations, is believed to be reliable. Users, however, should independentlyevaluate the suitability of each product <strong>for</strong> their application. Raychem makes no warranties as to theaccuracy or completeness of the in<strong>for</strong>mation, and disclaims any liability regarding its use. Raychem’sonly obligations are those in the Raychem Standard Terms and Conditions of Sale <strong>for</strong> this product,and in no case will Raychem be liable <strong>for</strong> any incidental, indirect, or consequential damages arisingfrom the sale, resale, use, or misuse of the product. Specifications are subject to change withoutnotice. In addition, Raychem reserves the right to make changes—without notification to Buyer—tomaterials or processing that do not affect compliance with any applicable specification.© 1994, 1995 Raychem Corporation Printed in USA H54785 10/96 <strong>TraceTek</strong> is a trademark of Raychem Corporation.