The IT earthing system (unearthed neutral) in LV

The IT earthing system (unearthed neutral) in LV

The IT earthing system (unearthed neutral) in LV

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

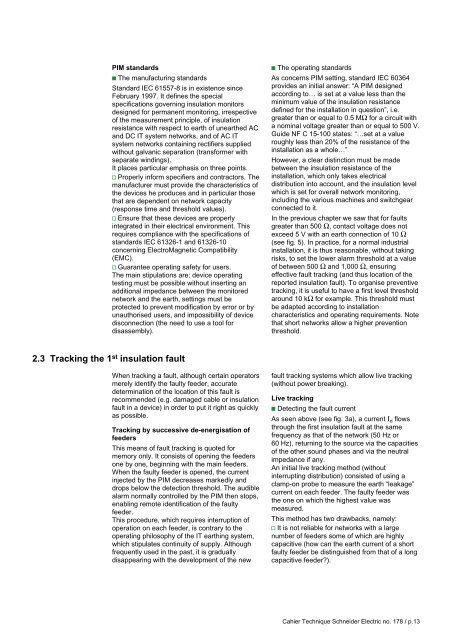

PIM standardsc <strong>The</strong> manufactur<strong>in</strong>g standardsStandard IEC 61557-8 is <strong>in</strong> existence s<strong>in</strong>ceFebruary 1997. It def<strong>in</strong>es the specialspecifications govern<strong>in</strong>g <strong>in</strong>sulation monitorsdesigned for permanent monitor<strong>in</strong>g, irrespectiveof the measurement pr<strong>in</strong>ciple, of <strong>in</strong>sulationresistance with respect to earth of <strong>unearthed</strong> ACand DC <strong>IT</strong> <strong>system</strong> networks, and of AC <strong>IT</strong><strong>system</strong> networks conta<strong>in</strong><strong>in</strong>g rectifiers suppliedwithout galvanic separation (transformer withseparate w<strong>in</strong>d<strong>in</strong>gs).It places particular emphasis on three po<strong>in</strong>ts.v Properly <strong>in</strong>form specifiers and contractors. <strong>The</strong>manufacturer must provide the characteristics ofthe devices he produces and <strong>in</strong> particular thosethat are dependent on network capacity(response time and threshold values).v Ensure that these devices are properly<strong>in</strong>tegrated <strong>in</strong> their electrical environment. Thisrequires compliance with the specifications ofstandards IEC 61326-1 and 61326-10concern<strong>in</strong>g ElectroMagnetic Compatibility(EMC).v Guarantee operat<strong>in</strong>g safety for users.<strong>The</strong> ma<strong>in</strong> stipulations are: device operat<strong>in</strong>gtest<strong>in</strong>g must be possible without <strong>in</strong>sert<strong>in</strong>g anadditional impedance between the monitorednetwork and the earth, sett<strong>in</strong>gs must beprotected to prevent modification by error or byunauthorised users, and impossibility of devicedisconnection (the need to use a tool fordisassembly).c <strong>The</strong> operat<strong>in</strong>g standardsAs concerns PIM sett<strong>in</strong>g, standard IEC 60364provides an <strong>in</strong>itial answer: “A PIM designedaccord<strong>in</strong>g to… is set at a value less than them<strong>in</strong>imum value of the <strong>in</strong>sulation resistancedef<strong>in</strong>ed for the <strong>in</strong>stallation <strong>in</strong> question”, i.e.greater than or equal to 0.5 MΩ for a circuit witha nom<strong>in</strong>al voltage greater than or equal to 500 V.Guide NF C 15-100 states: “…set at a valueroughly less than 20% of the resistance of the<strong>in</strong>stallation as a whole…”However, a clear dist<strong>in</strong>ction must be madebetween the <strong>in</strong>sulation resistance of the<strong>in</strong>stallation, which only takes electricaldistribution <strong>in</strong>to account, and the <strong>in</strong>sulation levelwhich is set for overall network monitor<strong>in</strong>g,<strong>in</strong>clud<strong>in</strong>g the various mach<strong>in</strong>es and switchgearconnected to it.In the previous chapter we saw that for faultsgreater than 500 Ω, contact voltage does notexceed 5 V with an earth connection of 10 Ω(see fig. 5). In practice, for a normal <strong>in</strong>dustrial<strong>in</strong>stallation, it is thus reasonable, without tak<strong>in</strong>grisks, to set the lower alarm threshold at a valueof between 500 Ω and 1,000 Ω, ensur<strong>in</strong>geffective fault track<strong>in</strong>g (and thus location of thereported <strong>in</strong>sulation fault). To organise preventivetrack<strong>in</strong>g, it is useful to have a first level thresholdaround 10 kΩ for example. This threshold mustbe adapted accord<strong>in</strong>g to <strong>in</strong>stallationcharacteristics and operat<strong>in</strong>g requirements. Notethat short networks allow a higher preventionthreshold.2.3 Track<strong>in</strong>g the 1 st <strong>in</strong>sulation faultWhen track<strong>in</strong>g a fault, although certa<strong>in</strong> operatorsmerely identify the faulty feeder, accuratedeterm<strong>in</strong>ation of the location of this fault isrecommended (e.g. damaged cable or <strong>in</strong>sulationfault <strong>in</strong> a device) <strong>in</strong> order to put it right as quicklyas possible.Track<strong>in</strong>g by successive de-energisation offeedersThis means of fault track<strong>in</strong>g is quoted formemory only. It consists of open<strong>in</strong>g the feedersone by one, beg<strong>in</strong>n<strong>in</strong>g with the ma<strong>in</strong> feeders.When the faulty feeder is opened, the current<strong>in</strong>jected by the PIM decreases markedly anddrops below the detection threshold. <strong>The</strong> audiblealarm normally controlled by the PIM then stops,enabl<strong>in</strong>g remote identification of the faultyfeeder.This procedure, which requires <strong>in</strong>terruption ofoperation on each feeder, is contrary to theoperat<strong>in</strong>g philosophy of the <strong>IT</strong> <strong>earth<strong>in</strong>g</strong> <strong>system</strong>,which stipulates cont<strong>in</strong>uity of supply. Althoughfrequently used <strong>in</strong> the past, it is graduallydisappear<strong>in</strong>g with the development of the newfault track<strong>in</strong>g <strong>system</strong>s which allow live track<strong>in</strong>g(without power break<strong>in</strong>g).Live track<strong>in</strong>gc Detect<strong>in</strong>g the fault currentAs seen above (see fig. 3a), a current I d flowsthrough the first <strong>in</strong>sulation fault at the samefrequency as that of the network (50 Hz or60 Hz), return<strong>in</strong>g to the source via the capacitiesof the other sound phases and via the neutralimpedance if any.An <strong>in</strong>itial live track<strong>in</strong>g method (without<strong>in</strong>terrupt<strong>in</strong>g distribution) consisted of us<strong>in</strong>g aclamp-on probe to measure the earth “leakage”current on each feeder. <strong>The</strong> faulty feeder wasthe one on which the highest value wasmeasured.This method has two drawbacks, namely:v It is not reliable for networks with a largenumber of feeders some of which are highlycapacitive (how can the earth current of a shortfaulty feeder be dist<strong>in</strong>guished from that of a longcapacitive feeder?).Cahier Technique Schneider Electric no. 178 / p.13