Atlas Copco 2008 â tough ending to a record year Annual Report ...

Atlas Copco 2008 â tough ending to a record year Annual Report ...

Atlas Copco 2008 â tough ending to a record year Annual Report ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

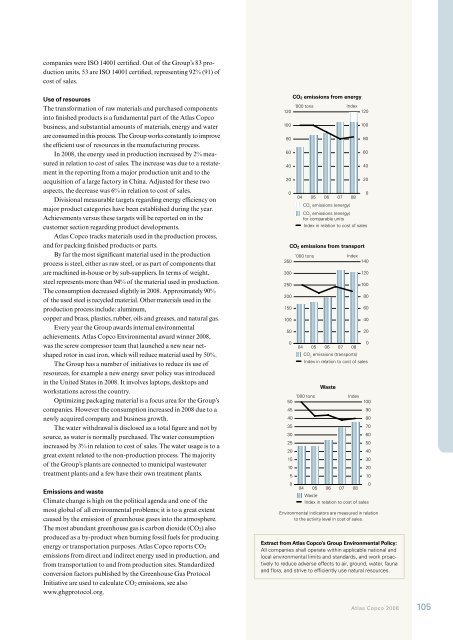

companies were ISO 14001 certified. Out of the Group’s 83 productionunits, 53 are ISO 14001 certified, representing 92% (91) ofcost of sales.Use of resourcesThe transformation of raw materials and purchased componentsin<strong>to</strong> finished products is a fundamental part of the <strong>Atlas</strong> <strong>Copco</strong>business, and substantial amounts of materials, energy and waterare consumed in this process. The Group works constantly <strong>to</strong> improvethe efficient use of resources in the manufacturing process.In <strong>2008</strong>, the energy used in production increased by 2% measuredin relation <strong>to</strong> cost of sales. The increase was due <strong>to</strong> a restatementin the reporting from a major production unit and <strong>to</strong> theacquisition of a large fac<strong>to</strong>ry in China. Adjusted for these twoaspects, the decrease was 6% in relation <strong>to</strong> cost of sales.Divisional measurable targets regarding energy efficiency onmajor product categories have been established during the <strong>year</strong>.Achievements versus these targets will be reported on in thecus<strong>to</strong>mer section regarding product developments.<strong>Atlas</strong> <strong>Copco</strong> tracks materials used in the production process,and for packing finished products or parts.By far the most significant material used in the productionprocess is steel, either as raw steel, or as part of components thatare machined in-house or by sub-suppliers. In terms of weight,steel represents more than 94% of the material used in production.The consumption decreased slightly in <strong>2008</strong>. Approximately 90%of the used steel is recycled material. Other materials used in theproduction process include: aluminum,copper and brass, plastics, rubber, oils and greases, and natural gas.Every <strong>year</strong> the Group awards internal environmentalachievements. <strong>Atlas</strong> <strong>Copco</strong> Environmental award winner <strong>2008</strong>,was the screw compressor team that launched a new near netshapedro<strong>to</strong>r in cast iron, which will reduce material used by 50%.The Group has a number of initiatives <strong>to</strong> reduce its use ofresources, for example a new energy saver policy was introducedin the United States in <strong>2008</strong>. It involves lap<strong>to</strong>ps, desk<strong>to</strong>ps andworkstations across the country.Optimizing packaging material is a focus area for the Group’scompanies. However the consumption increased in <strong>2008</strong> due <strong>to</strong> anewly acquired company and business growth.The water withdrawal is disclosed as a <strong>to</strong>tal figure and not bysource, as water is normally purchased. The water consumptionincreased by 3% in relation <strong>to</strong> cost of sales. The water usage is <strong>to</strong> agreat extent related <strong>to</strong> the non-production process. The majorityof the Group’s plants are connected <strong>to</strong> municipal wastewatertreatment plants and a few have their own treatment plants.Emissions and wasteClimate change is high on the political agenda and one of themost global of all environmental problems; it is <strong>to</strong> a great extentcaused by the emission of greenhouse gases in<strong>to</strong> the atmosphere.The most abundant greenhouse gas is carbon dioxide (CO 2) alsoproduced as a by-product when burning fossil fuels for producingenergy or transportation purposes. <strong>Atlas</strong> <strong>Copco</strong> reports CO 2emissions from direct and indirect energy used in production, andfrom transportation <strong>to</strong> and from production sites. Standardizedconversion fac<strong>to</strong>rs published by the Greenhouse Gas Pro<strong>to</strong>colInitiative are used <strong>to</strong> calculate CO 2 emissions, see alsowww.ghgpro<strong>to</strong>col.org.’000 <strong>to</strong>ns120100806040200300250200150100500’000 <strong>to</strong>ns50454035302520151050CO 2 emissions from energy0404050506Waste0607CO 2emissions (energy)CO 2emissions (energy)for comparable units07Index08Index0812010080604020Index in relation <strong>to</strong> cost of salesCO 2 emissions from transport’000 <strong>to</strong>ns3500405060708CO 2emissions (transports)100908070605040302010WasteIndex in relation <strong>to</strong> cost of sales0Index14012010080604020Index in relation <strong>to</strong> cost of salesEnvironmental indica<strong>to</strong>rs are measured in relation<strong>to</strong> the activity level in cost of sales.Extract from <strong>Atlas</strong> <strong>Copco</strong>’s Group Environmental Policy:All companies shall operate within applicable national andlocal environmental limits and standards, and work proactively<strong>to</strong> reduce adverse effects <strong>to</strong> air, ground, water, faunaand flora, and strive <strong>to</strong> efficiently use natural resources.00<strong>Atlas</strong> <strong>Copco</strong> <strong>2008</strong> 105