- Page 1:

NIST Technical Note 1455Performance

- Page 4 and 5:

Certain commercial entities, equipm

- Page 8 and 9:

2.5 Alarm Identification ..........

- Page 10 and 11:

7.5.3 Tell-tale Sprinklers ........

- Page 12 and 13:

Figure 37. Ion-1, six wicks 12 s de

- Page 14 and 15:

Figure 106. Gas temperatures from c

- Page 16 and 17:

Figure 161. Frying margarine scenar

- Page 18 and 19:

Figure 205. Bread in a toaster, fan

- Page 20 and 21:

xviii

- Page 22 and 23:

The fire emulator/detector evaluato

- Page 24 and 25:

installed close to cooking applianc

- Page 26 and 27:

xxiv

- Page 28 and 29:

Canada (NRCC), in conjunction with

- Page 30 and 31:

NIST, and others felt that it was t

- Page 32 and 33:

A second test site, obtained throug

- Page 34 and 35:

Thus typical residential sprinklers

- Page 37 and 38:

2 Residential Fire Alarms, Sensor R

- Page 39 and 40:

Figure 2. Schematic of the FE/DE (a

- Page 41 and 42:

urner fuel and air wereincremented

- Page 43 and 44:

Thus, within the range typical ofio

- Page 45 and 46:

k = ln( I / I ) L mextinction (m -1

- Page 47 and 48:

The test series are identified as S

- Page 49 and 50:

Detector Test Series a bm 0bm 1 R c

- Page 51 and 52:

87Obscuration (%/ft)654321Smolder s

- Page 53 and 54:

87Obscuration (%/ft)654321Smolder s

- Page 55 and 56:

Table 2. Listed unmodified alarm se

- Page 57 and 58:

1Laser Light Transmittance(1.52 m p

- Page 59 and 60:

1Laser Light Transmittance(1.52 m p

- Page 61 and 62:

Figures 28 - 37 show the results fo

- Page 63 and 64:

1Laser Light Transmittance(1.52 m p

- Page 65 and 66:

1Laser Light Transmittance(1.52 m p

- Page 67 and 68:

Laser Light Transmittance(1.52 m pa

- Page 69 and 70:

Laser Light Transmittance(1.52 m pa

- Page 71 and 72:

Laser Light Transmittance(1.52 m pa

- Page 73 and 74:

2.7 Effect of Sensor Board Location

- Page 75 and 76:

0.3Axial velocity 5 cm below ceilin

- Page 77 and 78:

0.7-5Laser Light Transmittance(1.52

- Page 79 and 80:

0.4-4Laser Light Transmittance(1.52

- Page 81 and 82:

0.5-5Laser Light Transmittance(1.52

- Page 83 and 84:

0.71Laser Light Transmittance(1.52m

- Page 85 and 86:

0.41Laser Light Transmittance(1.52m

- Page 87 and 88:

0.51Laser Light Transmittance(1.52m

- Page 89:

for all (modified) ionization alarm

- Page 92 and 93:

Table 6. Top fire scenarios ranked

- Page 94 and 95:

The flaming chair was chosen with a

- Page 96 and 97:

3.3 Ignition MethodologyThere were

- Page 98 and 99:

Figure 85 shows the smoldering rod

- Page 100 and 101:

20.12 m4.06 m2.34 m 1.68 m 2.59 m74

- Page 102 and 103:

3.34 m2.29 m 3.27 m0.53 mBath3.63 m

- Page 104 and 105:

temperature measurement in the diff

- Page 106 and 107:

1.04 m0.53 m0.80 m3.38 mTemperature

- Page 108 and 109:

4.2 Sample MassMass loss from the o

- Page 110 and 111:

With different line lengths, vacuum

- Page 112 and 113:

Table 9. Locations for primary opti

- Page 114 and 115:

Finally, a size distribution measur

- Page 116 and 117:

of the limited supply of analog-mod

- Page 119 and 120:

5 Fire Source Test Results and Calc

- Page 121 and 122: Table 12. Test Conditions for tests

- Page 123 and 124: Remote Bedroom45Temperature (°C)40

- Page 125 and 126: Hallway Outside Remote Bedroom70Tem

- Page 127 and 128: Living Room60Temperature (°C)50403

- Page 129 and 130: Closed Bedroom301520 mm25Temperatur

- Page 131 and 132: Remote Bedroom2.52.020 mm900 mmOpti

- Page 133 and 134: Hallway Outside Remote Bedroom1.41.

- Page 135 and 136: Living Room2.52.020 mm900 mmOptical

- Page 137 and 138: Closed Bedroom0.10Initiation of Sup

- Page 139 and 140: Carbon Dioxide2.01.5Remote BedroomM

- Page 141 and 142: Smoke Alarm Output10030Smoke Alarm

- Page 143 and 144: Heat Alarm-600Initiation of Suppres

- Page 145 and 146: • carbon monoxide alarms - 50 x 1

- Page 147 and 148: 5.4.2 Tenability TimesChapter 8 of

- Page 149 and 150: Alarm Code was revised to require s

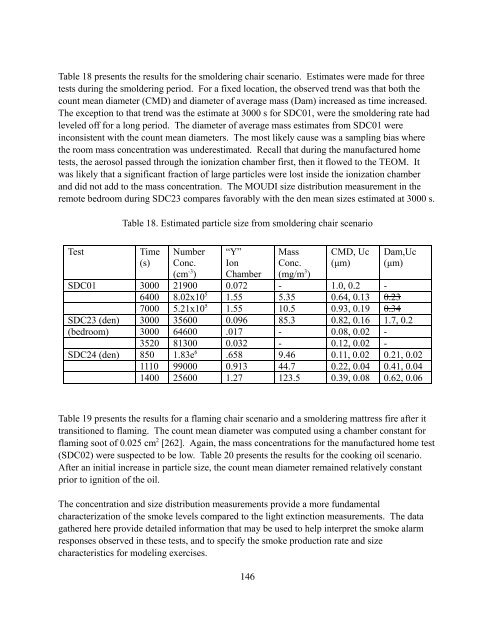

- Page 151 and 152: Measurements of the aerosol number

- Page 153 and 154: ANumber Concentration (particles/cm

- Page 155 and 156: Number Concentration (particles/cm3

- Page 157 and 158: ANumber Concentration (particles/cm

- Page 159 and 160: ANumber Concentration (particles/cm

- Page 161 and 162: 10 6 Number0.8Ion 110 5Ion 2Ion 3Io

- Page 163 and 164: SDC24 was a cooking oil fire in the

- Page 165 and 166: 5002Mass Concentration (mg/m3)37525

- Page 167 and 168: Table 17. Cascade impactor resultsT

- Page 169 and 170: 50 % cut-off Diameter(μm)1010.1MMA

- Page 171: 50 % cut-off Diameter(μm)1010.1MMA

- Page 175 and 176: 6 Residential Smoke Alarm Nuisance

- Page 177 and 178: A2ARHCBA1DEA3FGU+V+Figure 141. Sche

- Page 179 and 180: lags the MIC current due to the tim

- Page 181 and 182: On several occasions, the SBC data

- Page 183 and 184: 0.50.5Velocity or Speed (m/s)0.250-

- Page 185 and 186: One can still observe trends in the

- Page 187 and 188: Time to Alarm Threshold (s)A6005004

- Page 189 and 190: Time to Alarm Threshold (s)A4003503

- Page 191 and 192: • Photoelectric alarm thresholds

- Page 193 and 194: trend and both experience two peak

- Page 195 and 196: Figure 156 shows the results for ba

- Page 197 and 198: Time to Alarm Threshold (s)A6005004

- Page 199 and 200: Time to Alarm Threshold (s)A4003002

- Page 201 and 202: Figure 161 shows the results for ma

- Page 203 and 204: ose about 2 %. The mass concentrati

- Page 205 and 206: Time to Alarm Threshold (s)A7006005

- Page 207 and 208: photoelectric alarms; however one c

- Page 209 and 210: 6.3.6 Broiled and Baked/Broiled Piz

- Page 211 and 212: Time to Alarm Threshold (s)A1300120

- Page 213 and 214: 6.3.7 Broiling HamburgersFour 110 g

- Page 215 and 216: Time to Alarm Threshold (s)A1000800

- Page 217 and 218: Time to Alarm Threshold (s)A6005004

- Page 219 and 220: 6.3.9 Candle BurningFour scented te

- Page 221 and 222: Time to Alarm Threshold (s)A1008060

- Page 223 and 224:

ealizing the early peak, then climb

- Page 225 and 226:

• A somewhat counterintuitive obs

- Page 227 and 228:

Time to Alarm Threshold (s)A1300120

- Page 229 and 230:

Time to Alarm Threshold (s)A8006004

- Page 231 and 232:

Time to Alarm Threshold (s)A8007006

- Page 233 and 234:

6.5 FE/DE Emulation of Nuisance Sou

- Page 235 and 236:

10080MICD1D86050MIC Current (pA)604

- Page 237 and 238:

6.5.2 Cotton Smolder Smoke Fire Sce

- Page 239 and 240:

0.50.4ExtinctionMIC1008010080MICD1D

- Page 241 and 242:

0.250.2ExtinctionMIC1008010080MICD1

- Page 243 and 244:

0.80.70.6ExtinctionMIC1008010080MIC

- Page 245 and 246:

0.50.4ExtinctionMIC100908010080MICD

- Page 247 and 248:

6.5.5 Heated Margarine or Butter Nu

- Page 249 and 250:

Extinction (m -1 )A0.0350.030.0250.

- Page 251 and 252:

21.5ExtinctionMIC1008010080MICD1D86

- Page 253 and 254:

21.5ExtinctionMIC1008010080MICD1D86

- Page 255 and 256:

2.521008010080MICD1D86050Extinction

- Page 257 and 258:

7 DiscussionIn 1975, the Indiana Du

- Page 259 and 260:

one of the Dual Ion/Photo alarms in

- Page 261 and 262:

Table 24. Average time to alarm (in

- Page 263 and 264:

series of actions beginning with cu

- Page 265 and 266:

Distances are taken as straight lin

- Page 267 and 268:

On average, the photoelectric alarm

- Page 269 and 270:

Table 28. Available egress time (in

- Page 271 and 272:

800700600PhotoIonDual Ion/PhotoAspi

- Page 273 and 274:

protection against injury, life los

- Page 275 and 276:

ate of fire growth (table 32). Aver

- Page 277 and 278:

The FE/DE nuisance source tests cap

- Page 279 and 280:

8 SummaryThe data developed in this

- Page 281 and 282:

4. Develop standard nuisance alarm

- Page 283 and 284:

Finally, a press day was held that

- Page 285 and 286:

9 Conclusions1. The data developed

- Page 287 and 288:

10 References[1] Bukowski, R. W., W

- Page 289 and 290:

[23] The SFPE Handbook of Fire Prot

- Page 291 and 292:

[48] Bryan, J. L. “Project People

- Page 293 and 294:

Calculated Alarm Times

- Page 295 and 296:

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

- Page 297 and 298:

Test SDC03 Smoldering Mattress in B

- Page 299 and 300:

Test SDC05 Flaming Mattress in Bedr

- Page 301 and 302:

Test SDC07 Flaming Mattress in Bedr

- Page 303 and 304:

Test SDC09 Flaming Mattress in Bedr

- Page 305 and 306:

Test SDC11 Smoldering Chair in Livi

- Page 307 and 308:

Test SDC13 Vegetable Oil on Kitchen

- Page 309 and 310:

Test SDC15 Flaming Chair Living Roo

- Page 311 and 312:

Test SDC21 Smoldering Mattress in B

- Page 313 and 314:

Test SDC23 Smoldering Chair in Livi

- Page 315 and 316:

Test SDC25 Flaming Chair in Living

- Page 317 and 318:

Test SDC27 Smoldering Chair in Livi

- Page 319 and 320:

Series ..\Manufactured Home Series

- Page 321 and 322:

Test SDC32 Flaming Chair in Living

- Page 323 and 324:

Test SDC35 Flaming Chair in Living

- Page 325 and 326:

Test SDC37 Smoldering Mattress in B

- Page 327 and 328:

Test SDC39 Flaming Mattress in Bedr

- Page 329 and 330:

Test SDC41 Vegetable Oil on Kitchen

- Page 331 and 332:

12345678910111213141516171819202122

- Page 333 and 334:

81828384858687888990919293949596979

- Page 335 and 336:

15715815916016116216316416516616716

- Page 337 and 338:

23323423523623723823924024124224324

- Page 339 and 340:

30730830931031131231331431531631731

- Page 341 and 342:

38138238338438538638738838939039139

- Page 343 and 344:

45645745845946046146246346446546646

- Page 345 and 346:

52752852953053153253353453553653753

- Page 347 and 348:

60260360460560660760860961061161261

- Page 349 and 350:

67867968068168268368468568668768868

- Page 351 and 352:

75475575675775875976076176276376476

- Page 353 and 354:

83083183283383483583683783883984084

- Page 355 and 356:

90690790890991091191291391491591691

- Page 357 and 358:

98298398498598698798898999099199299

- Page 359 and 360:

10661067106810691070107110721073107

- Page 361 and 362:

11541155115611571158115911601161116

- Page 363 and 364:

12421243124412451246124712481249125

- Page 365 and 366:

13301331133213331334133513361337133

- Page 367 and 368:

Appendix BFTIR Gas Measurement in H

- Page 369 and 370:

FTIR GAS MEASUREMENT IN HOME SMOKE

- Page 371 and 372:

Figure 16. Average of spectra for t

- Page 373 and 374:

2.0 EXPERIMENTSExperimental details

- Page 375 and 376:

Figure 1. Manufactured home and FTI

- Page 377 and 378:

Figure 3. Upholstered chairs before

- Page 379 and 380:

3.0 RESULTS AND DISCUSSIONA total o

- Page 381 and 382:

and 500°C in Test 7. Figure 19 sho

- Page 383 and 384:

.05.04Absorbance.03.02CO2CO2.010H2O

- Page 385 and 386:

.05.04Absorbance.03.02H2OH2O.01CO20

- Page 387 and 388:

.2CO2CO2.15Absorbance.1.05H2OH2O0CO

- Page 389 and 390:

.1.08.050Absorbance.06.04CO2-.05720

- Page 391 and 392:

.14.12.1CO2CO2Absorbance.08.06.04.0

- Page 393 and 394:

1.41.2NDIRFTIR1.00.8CO 2[%]0.60.40.

- Page 395 and 396:

0.050.04NDIRFTIR0.03CO [%]0.020.010