Liebert Mini-Mate2, 8 Ton - Emerson Network Power

Liebert Mini-Mate2, 8 Ton - Emerson Network Power

Liebert Mini-Mate2, 8 Ton - Emerson Network Power

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

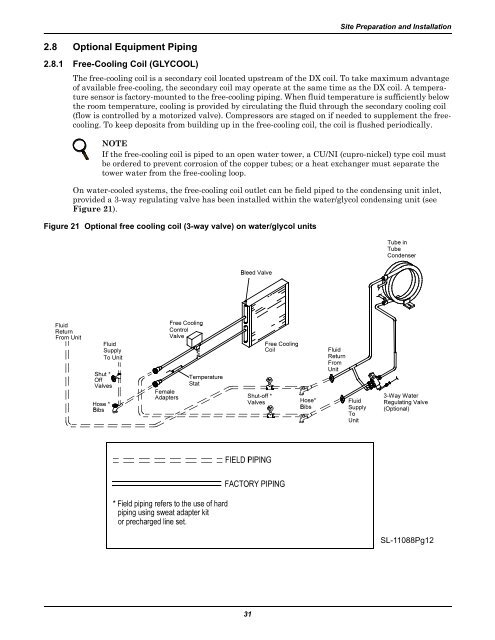

2.8 Optional Equipment Piping<br />

2.8.1 Free-Cooling Coil (GLYCOOL)<br />

31<br />

Site Preparation and Installation<br />

The free-cooling coil is a secondary coil located upstream of the DX coil. To take maximum advantage<br />

of available free-cooling, the secondary coil may operate at the same time as the DX coil. A temperature<br />

sensor is factory-mounted to the free-cooling piping. When fluid temperature is sufficiently below<br />

the room temperature, cooling is provided by circulating the fluid through the secondary cooling coil<br />

(flow is controlled by a motorized valve). Compressors are staged on if needed to supplement the freecooling.<br />

To keep deposits from building up in the free-cooling coil, the coil is flushed periodically.<br />

NOTE<br />

If the free-cooling coil is piped to an open water tower, a CU/NI (cupro-nickel) type coil must<br />

be ordered to prevent corrosion of the copper tubes; or a heat exchanger must separate the<br />

tower water from the free-cooling loop.<br />

On water-cooled systems, the free-cooling coil outlet can be field piped to the condensing unit inlet,<br />

provided a 3-way regulating valve has been installed within the water/glycol condensing unit (see<br />

Figure 21).<br />

Figure 21 Optional free cooling coil (3-way valve) on water/glycol units<br />

SL-11088Pg12