Liebert Mini-Mate2, 8 Ton - Emerson Network Power

Liebert Mini-Mate2, 8 Ton - Emerson Network Power

Liebert Mini-Mate2, 8 Ton - Emerson Network Power

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

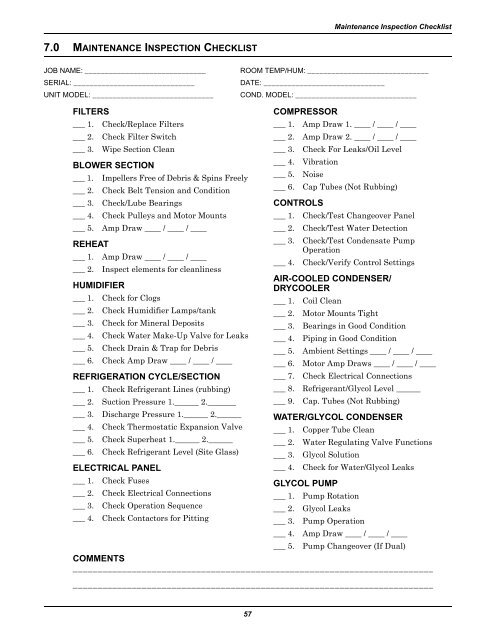

7.0 MAINTENANCE INSPECTION CHECKLIST<br />

57<br />

Maintenance Inspection Checklist<br />

JOB NAME: ______________________________ ROOM TEMP/HUM: ______________________________<br />

SERIAL: ______________________________ DATE: ______________________________<br />

UNIT MODEL: ______________________________ COND. MODEL: ______________________________<br />

FILTERS<br />

COMPRESSOR<br />

___ 1. Check/Replace Filters<br />

___ 1. Amp Draw 1. ____ / ____ / ____<br />

___ 2. Check Filter Switch<br />

___ 2. Amp Draw 2. ____ / ____ / ____<br />

___ 3. Wipe Section Clean<br />

___ 3. Check For Leaks/Oil Level<br />

BLOWER SECTION<br />

___ 4. Vibration<br />

___ 1. Impellers Free of Debris & Spins Freely<br />

___ 5. Noise<br />

___ 2. Check Belt Tension and Condition<br />

___ 6. Cap Tubes (Not Rubbing)<br />

___ 3. Check/Lube Bearings<br />

CONTROLS<br />

___ 4. Check Pulleys and Motor Mounts<br />

___ 1. Check/Test Changeover Panel<br />

___ 5. Amp Draw ____ / ____ / ____<br />

___ 2. Check/Test Water Detection<br />

REHEAT<br />

___ 1. Amp Draw ____ / ____ / ____<br />

___ 2. Inspect elements for cleanliness<br />

___ 3.<br />

___ 4.<br />

Check/Test Condensate Pump<br />

Operation<br />

Check/Verify Control Settings<br />

HUMIDIFIER<br />

AIR-COOLED CONDENSER/<br />

DRYCOOLER<br />

___ 1. Check for Clogs<br />

___ 1. Coil Clean<br />

___ 2. Check Humidifier Lamps/tank<br />

___ 2. Motor Mounts Tight<br />

___ 3. Check for Mineral Deposits<br />

___ 3. Bearings in Good Condition<br />

___ 4. Check Water Make-Up Valve for Leaks ___ 4. Piping in Good Condition<br />

___ 5. Check Drain & Trap for Debris<br />

___ 5. Ambient Settings ____ / ____ / ____<br />

___ 6. Check Amp Draw ____ / ____ / ____<br />

___ 6. Motor Amp Draws ____ / ____ / ____<br />

REFRIGERATION CYCLE/SECTION<br />

___ 7. Check Electrical Connections<br />

___ 1. Check Refrigerant Lines (rubbing)<br />

___ 8. Refrigerant/Glycol Level ______<br />

___ 2. Suction Pressure 1.______ 2._______ ___ 9. Cap. Tubes (Not Rubbing)<br />

___ 3. Discharge Pressure 1.______ 2.______ WATER/GLYCOL CONDENSER<br />

___ 4. Check Thermostatic Expansion Valve ___ 1. Copper Tube Clean<br />

___ 5. Check Superheat 1.______ 2.______<br />

___ 2. Water Regulating Valve Functions<br />

___ 6. Check Refrigerant Level (Site Glass) ___ 3. Glycol Solution<br />

ELECTRICAL PANEL<br />

___ 4. Check for Water/Glycol Leaks<br />

___ 1. Check Fuses<br />

GLYCOL PUMP<br />

___ 2. Check Electrical Connections<br />

___ 1. Pump Rotation<br />

___ 3. Check Operation Sequence<br />

___ 2. Glycol Leaks<br />

___ 4. Check Contactors for Pitting<br />

___ 3. Pump Operation<br />

___ 4. Amp Draw ____ / ____ / ____<br />

___ 5. Pump Changeover (If Dual)<br />

COMMENTS<br />

_________________________________________________________________________<br />

_________________________________________________________________________