Smart Industry 1/2016

Smart Industry 1/2016 - The IoT Business Magazine - powered by Avnet Silica

Smart Industry 1/2016 - The IoT Business Magazine - powered by Avnet Silica

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Setting Standards<br />

for <strong>Smart</strong> Chips<br />

■ Industrie 4.0<br />

The German industry is getting serious<br />

about “Industrie 4.0”, as the Industrial<br />

Internet is called in that country. At<br />

the recent Hanover Industrial Fair, a<br />

group consisting of virtually all the<br />

major industry associations involved<br />

in manufacture and electronics got<br />

together to found the “Standardization<br />

Council Industrie 4.0” which will be<br />

tasked with helping to create national<br />

and international standards and reference<br />

architectures for IoT applications.<br />

Recognizing that Germany lags behind<br />

others in IoT readiness, the Council will<br />

seek to establish working groups with<br />

associations in other European countries<br />

to create a counterbalance to U.S. domination<br />

in this fi eld. Members include the<br />

Society of German Engineers (VDE), the<br />

IT industry association Bitkom, as well as<br />

the Electronics <strong>Industry</strong> Association ZVEI<br />

and the standards body DIN.<br />

Michael Scholles, who also works for<br />

Fraunhofer’s IPMS. According to him,<br />

the high cost of more powerful <strong>Smart</strong><br />

Sensors is still prohibitive in many<br />

cases, but they are necessary for most<br />

high-value projects in the realm of<br />

IoT. “We need to see a substantial reduction<br />

in sensors’ prices sometime<br />

soon”, he believes. Since wafer space<br />

in semiconductor manufacturing is<br />

limited, the best way to make sensors<br />

cheaper, he believes, is to reduce their<br />

size so you can fit more them on each<br />

substrate. Adding extra technology<br />

to the silicon is not the best idea, he<br />

thinks; a better way would be to try<br />

and combine existing chips in order<br />

to avoid the high costs of developing<br />

new ones.<br />

Dr. Gunther Kegel, the vice president<br />

of the German Engineering Society<br />

(VDE) and CEO of Peperl+Fuchs, an<br />

SME specializing in factory automation<br />

systems, agrees. “The large investment<br />

necessary to create more highly<br />

integrated chips is self-defeating”, he<br />

believes. His solution is to “borrow”<br />

existing technology from other fields.<br />

“Sensors can be made universally<br />

adaptable”, says KIT’s Prof. Beigl, “the<br />

subsequent production steps can’t.”<br />

In order to be integrated into complex<br />

manufacturing processes, systems<br />

need to be easily customized. And in<br />

order to keep the number-crunching<br />

costs as low as possible, reference<br />

architectures and know-how transfer<br />

will be necessary, he believes, if SMEs<br />

are to be able to become the future<br />

champions in a world of IoT. If not,<br />

they will be priced out of the market.<br />

Security is the other big issue companies<br />

worry about when considering<br />

whether to move to <strong>Smart</strong> Sensors.<br />

This is especially true for smaller companies,<br />

especially since most sensors<br />

are manufactured in the Far East or in<br />

America where data protection and<br />

privacy rules are perceived as less<br />

strict than in Europe. They fear that<br />

the quality of their products could sink<br />

and they themselves be swamped by<br />

legal suits brought against them by<br />

irate customers.<br />

“IoT must be fully protected against<br />

shoddy sensors and manipulated<br />

data”, says Oliver Winzenried, CEO of<br />

Wibu Systems, a cybersecurity company.<br />

Sensors should be able to au-<br />

In order to be<br />

integrated into<br />

complex manufacturing<br />

processes,<br />

smart<br />

sensors need<br />

to be easily<br />

customized.<br />

Prof. Michael Beigl<br />

Karlsruhe Institute of<br />

Technology (KIT)<br />

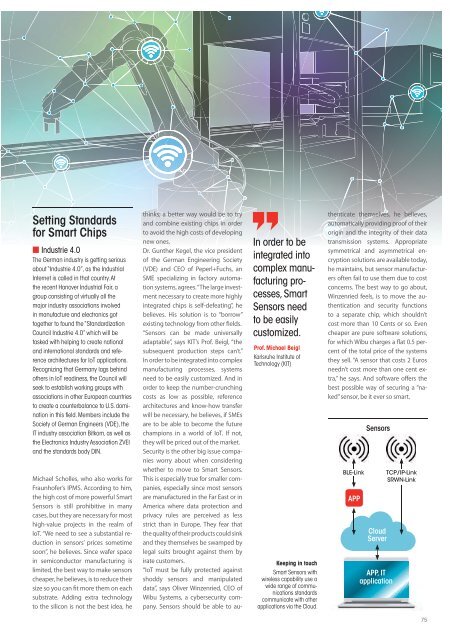

Keeping in touch<br />

<strong>Smart</strong> Sensors with<br />

wireless capability use a<br />

wide range of communications<br />

standards<br />

communicate with other<br />

applications via the Cloud.<br />

thenticate themselves, he believes,<br />

automatically providing proof of their<br />

origin and the integrity of their data<br />

transmission systems. Appropriate<br />

symmetrical and asymmetrical encryption<br />

solutions are available today,<br />

he maintains, but sensor manufacturers<br />

often fail to use them due to cost<br />

concerns. The best way to go about,<br />

Winzenried feels, is to move the authentication<br />

and security functions<br />

to a separate chip, which shouldn’t<br />

cost more than 10 Cents or so. Even<br />

cheaper are pure software solutions,<br />

for which Wibu charges a flat 0.5 percent<br />

of the total price of the systems<br />

they sell. “A sensor that costs 2 Euros<br />

needn’t cost more than one cent extra,”<br />

he says. And software offers the<br />

best possible way of securing a “naked”<br />

sensor, be it ever so smart.<br />

BLE-Link<br />

APP<br />

Sensors<br />

Cloud<br />

Server<br />

APP, IT<br />

application<br />

TCP/IP-Link<br />

SRWN-Link<br />

75