- Page 1:

- ISO 9001 CATALOG 13 ~1 SPAENAUR A

- Page 4 and 5:

, ' '· I . ~ I l " .•. 4 .... ,

- Page 6 and 7:

Nous sommes pret a vous servir •

- Page 8 and 9:

It's Easy to Buy from Spaenaur How

- Page 10 and 11:

Assortments and Storage Products As

- Page 12 and 13:

Inch Pouces LARGE SIZE Assortments

- Page 14 and 15:

Inch Pouces EMPTY PLASTIKITS 176-E

- Page 16 and 17:

Inch and Metric Pouces et Métrique

- Page 18 and 19:

Inch and Metric Pouces et Métrique

- Page 20 and 21:

Inch and Metric Pouces et Métrique

- Page 22 and 23:

Inch and Metric Pouces et Métrique

- Page 24 and 25:

Inch and Metric Pouces et Métrique

- Page 26 and 27:

Inch and Metric Pouces et Métrique

- Page 28 and 29:

Inch and Metric Pouces et Métrique

- Page 30 and 31:

Inch and Metric Pouces et Métrique

- Page 32 and 33:

Inch and Metric Pouces et Métrique

- Page 34 and 35:

Inch and Metric Pouces et Métrique

- Page 36 and 37:

Inch and Metric Pouces et Métrique

- Page 38 and 39:

Inch and Metric Pouces et Métrique

- Page 40 and 41:

(*814-498T) *Replacement Insert Tra

- Page 42 and 43:

(*814-698T) (*Replacement Insert Tr

- Page 44 and 45:

Plastic Compartment Boxes Boîtes p

- Page 46 and 47:

... DRAWER CABINETS continued Heavy

- Page 48 and 49:

... DRAWER CABINETS continued Heavy

- Page 50 and 51:

Heavy Duty Welded Steel STORAGE BIN

- Page 52 and 53:

Storage Units In addition to a wide

- Page 54 and 55:

Heavy Duty Welded Steel Storage Bin

- Page 56 and 57:

Durham Literature Racks provide a c

- Page 58 and 59:

Tool Storage Systems Système d'emm

- Page 60 and 61:

Storage/Assortment Cases Trousse d'

- Page 62 and 63:

Storage Cases Méthode d'emmagasina

- Page 64 and 65:

SCREWS & BOLTS (General Data) Donn

- Page 66 and 67:

B “LONG-LOK” «Long-Lok» LOCKI

- Page 68 and 69:

B Machine Screws - Slot Drive Vis m

- Page 70 and 71:

B Machine Screws - Slot Drive Vis m

- Page 72 and 73:

B Machine Screws - Slot Drive Vis m

- Page 74 and 75:

Assortments Assortiments Inch Pouce

- Page 76 and 77:

Assortments • Plastikits Plastiki

- Page 78 and 79:

Machine Screws - Slot Drive Vis mé

- Page 80 and 81:

B Machine Screws - Slot Drive Vis m

- Page 82 and 83:

Machine Screws - Slot Drive Vis mé

- Page 84 and 85:

B Machine Screws - Slot Drive Vis m

- Page 86 and 87:

B Machine Screws - Slot Drive Vis m

- Page 88 and 89:

B Machine Screws - Slot Drive Vis m

- Page 90 and 91:

Nylon Metal-Core Screws Vis en nylo

- Page 92 and 93:

B Machine Screws - Phillips Drive V

- Page 94 and 95:

B Assortments - Machine Screws Asso

- Page 96 and 97:

B Machine Screws - Phillips Drive V

- Page 98 and 99:

Machine Screws Square Socket Drive

- Page 100 and 101:

B Machine Screws Combination Sq. So

- Page 102 and 103:

B Machine Screws - Slot Drive Vis m

- Page 104 and 105:

B Machine Screws - Slot Drive Vis m

- Page 106 and 107:

B Machine Screws - Slot Drive Vis m

- Page 108 and 109:

B Machine Screws - Slot Drive Vis m

- Page 110 and 111:

Machine Screws - Slot Drive Vis mé

- Page 112 and 113:

B Machine Screws - Slot Drive Vis m

- Page 114 and 115:

Machine Screws - Slot Drive Vis mé

- Page 116 and 117:

Machine Screws - Slot Drive Vis mé

- Page 118 and 119:

B Machine Screws - Slot Drive Vis m

- Page 120 and 121:

B Machine Screws - Slot Drive Vis m

- Page 122 and 123:

B Machine Screws - Slot Drive Vis m

- Page 124 and 125:

B Machine Screws - Slot Drive Vis m

- Page 126 and 127:

B Regular Size ASSORTMENTS ASSORTIM

- Page 128 and 129:

B Machine Screws - Phillips Drive V

- Page 130 and 131:

B Machine Screws - Phillips Drive V

- Page 132 and 133:

B Threaded Inserts for Wood Pièces

- Page 134 and 135:

• Joint Connector Nuts Écrous po

- Page 136 and 137:

Wood Screws - Slot Drive Vis à boi

- Page 138 and 139:

B Wood Screws - Slot Drive Vis à b

- Page 140 and 141:

Wood Screws - Square Socket Drive V

- Page 142 and 143:

B Wood Screws - Square Socket Drive

- Page 144 and 145:

B Wood Screws - Torx ® Drive Vis

- Page 146 and 147:

B Wood Screws - Square Socket Drive

- Page 148 and 149:

B Wood Screws - Square Socket Drive

- Page 150 and 151:

B Wood Screws - Square Socket Drive

- Page 152 and 153:

B Concrete Fastening System Inch Sy

- Page 154 and 155:

B Concrete Fastening System Systèm

- Page 156 and 157:

Inch Pouces SPECIAL ASSORTMENT ASSO

- Page 158 and 159:

Inch Pouces Hardened STEEL Inch Siz

- Page 160 and 161:

CATALOG 13 Inch Pouces Hardened STE

- Page 162 and 163:

CATALOG 13 Inch Pouces ASS'T. DIA.

- Page 164 and 165:

CATALOG 13 Inch Pouces INCH Sizes N

- Page 166 and 167:

Metric Métrique TORX ® DRIVE - Ta

- Page 168 and 169:

Inch Pouces SPECIAL ASSORTMENT - AS

- Page 170 and 171:

Inch Pouces Hardened STEEL ZINC PLA

- Page 172 and 173:

Inch Pouces 410 HEX WASHER HEAD L P

- Page 174 and 175:

Inch Pouces TEKS ® Self-Drilling S

- Page 176 and 177:

Inch Pouces STAINLESS STEEL TAPPING

- Page 178 and 179:

Inch Pouces Priced Singly ASSORTMEN

- Page 180 and 181:

Inch Pouces Thread-Cutting Screws V

- Page 182 and 183:

Inch Pouces RECOMMENDED PILOT HOLE

- Page 184 and 185:

CATALOG 13 Inch Pouces FLORTORX SCR

- Page 186 and 187:

CATALOG 13 Inch Pouces STEEL SPAENA

- Page 188 and 189:

CATALOG 13 Inch and Metric Pouces e

- Page 190 and 191:

CATALOG 13 Inch Pouces SECURITY HEX

- Page 192 and 193:

Inch Pouces SECURITY PHILLIPS DRIVE

- Page 194 and 195:

Inch Pouces TORX ® TAMPER-RESISTAN

- Page 196 and 197:

CATALOG 13 Inch Pouces Machine Scre

- Page 198 and 199:

Inch and Metric Pouces et Métrique

- Page 200 and 201:

Inch Pouces STEEL PHILLIPS DRIVE (C

- Page 202 and 203:

Inch Pouces STEEL “SEMS” Machin

- Page 204 and 205:

Inch Pouces STEEL Case-hardened to

- Page 206 and 207:

Metric Métrique STEEL “SEMS” A

- Page 208 and 209:

Metric Métrique Automotive and Spe

- Page 210 and 211:

B Bumper-Bar Bolts Boulons de barre

- Page 212 and 213:

Self-Clinching Fasteners Attaches a

- Page 214 and 215:

B Self-Clinching Studs Goujons auto

- Page 216 and 217:

B Weld Screws Vis à souder E G 120

- Page 218 and 219:

B Weld Screws Vis à souder 120° R

- Page 220 and 221:

Weld Pins Goupille à souder ® Inc

- Page 222 and 223:

B Hexagon Cap Screws Boulons de pr

- Page 224 and 225:

B HEXAGON Cap Screws Boulons de pr

- Page 226 and 227:

B HEXAGON Cap Screws Boulons de pr

- Page 228 and 229:

B HEXAGON Cap Screws Boulons de pr

- Page 230 and 231:

Heavy Hex Structural Bolts Boulons

- Page 232 and 233:

B HEXAGON Cap Screws Boulons de pr

- Page 234 and 235:

B HEXAGON Cap Screws Boulons de pr

- Page 236 and 237:

B L • 9 ® Fastening System Syst

- Page 238 and 239:

B HEXAGON Bolts Boulons HEXAGONAUX

- Page 240 and 241:

B L • 9 ® Fastening System Syst

- Page 242 and 243:

L • 9 ® Fastening System Systèm

- Page 244 and 245:

B HEXAGON Cap Screws Boulons de pr

- Page 246 and 247:

B HEXAGON Cap Screws Boulons de pr

- Page 248 and 249:

HEXAGON Cap Screws Boulons de préc

- Page 250 and 251:

B HEXAGON Cap Screws Boulons de pr

- Page 252 and 253:

B HEXAGON Cap Screws Boulons de pr

- Page 254 and 255:

B HEXAGON Cap Screws Boulons de pr

- Page 256 and 257:

B HEXAGON Cap Screws Boulons de pr

- Page 258 and 259:

HEXAGON Cap Screws Boulons de préc

- Page 260 and 261:

HEXAGON Cap Screws Boulons de préc

- Page 262 and 263:

B HEXAGON Cap Screws Boulons de pr

- Page 264 and 265:

B HEXAGON Cap Screws Boulons de pr

- Page 266 and 267:

HEXAGON Cap Screws Boulons de préc

- Page 268 and 269:

B HEXAGON Cap Screws Boulons de pr

- Page 270 and 271:

Torque Data - 1960 Series ® Donné

- Page 272 and 273:

CATALOG 13 Inch ® Pouces continued

- Page 274 and 275:

Inch Pouces ® Assortments Assortim

- Page 276 and 277:

B Hex Socket Cap Screws Vis à têt

- Page 278 and 279:

Hex Socket Cap Screws Vis à tête

- Page 280 and 281:

Hex Socket Cap Screws Boulons de pr

- Page 282 and 283:

Hex Socket Cap Screws Boulons de pr

- Page 284 and 285:

B Hex Socket Cap Screws Boulons de

- Page 286 and 287:

Hex Socket Cap Screws Boulons de pr

- Page 288 and 289:

A B Hex Socket Set Screws Vis de pr

- Page 290 and 291:

A B Hex Socket Set Screws Vis de pr

- Page 292 and 293:

A B Hex Socket Set Screws Vis de pr

- Page 294 and 295:

B Hex Socket Cap Screws Vis à têt

- Page 296 and 297:

B Hex Socket Cap Screws Vis à têt

- Page 298 and 299:

B Hex Socket Cap Screws Boulons de

- Page 300 and 301:

B Hex Socket Cap Screws Vis à têt

- Page 302 and 303:

B “PELLETIZED” Hex Socket Cap S

- Page 304 and 305:

B Hex Socket Cap Screws Vis à têt

- Page 306 and 307:

Hex Socket Shoulder Screws Vis à

- Page 308 and 309:

B Countr-Bor Screws Vis «Countr-Bo

- Page 310 and 311:

Hex Socket Cap Screws Vis à tête

- Page 312 and 313:

Hex Socket Cap Screws Vis à tête

- Page 314 and 315:

B Hex Socket Cap Screws Vis à têt

- Page 316 and 317:

B Hex Socket Cap Screws Vis à têt

- Page 318 and 319:

Hex Socket Cap Screws Vis à tête

- Page 320 and 321:

Metric Métrique Hex Socket Cap Scr

- Page 322 and 323:

Metric Métrique Hex Socket Cap Scr

- Page 324 and 325:

Metric Métrique Hex Socket Cap Scr

- Page 326 and 327:

Metric Métrique Hex Socket Cap Scr

- Page 328 and 329:

Metric Métrique Hex Socket Cap Scr

- Page 330 and 331:

Metric Métrique DIN 7991 Fully Thr

- Page 332 and 333:

Hex Socket Cap Screws Vis à 6 pans

- Page 334 and 335:

CATALOG 13 Metric Métrique ALLOY S

- Page 336 and 337:

Metric Métrique METRIC BLUE ® HIG

- Page 338 and 339:

Metric Métrique Cross-Drilled Hex

- Page 340 and 341:

Metric Métrique Hex Nuts Écrous h

- Page 342 and 343:

Metric Métrique METRIC BLUE ® HIG

- Page 344 and 345:

Inch Pouces ALLOY STEEL DIA. THD. L

- Page 346 and 347:

Inch Pouces STEEL Not Plated CUP PO

- Page 348 and 349:

Inch Pouces Hex Socket Set Screws V

- Page 350 and 351:

Inch Pouces NYLON TIP - BOUT DE NYL

- Page 352 and 353:

Inch Pouces HEX SOCKET SET SCREWS w

- Page 354 and 355:

CATALOG 13 Inch Pouces NYLON (Natur

- Page 356 and 357:

Metric Métrique METRIC SLOTTED GRU

- Page 358 and 359:

Metric Métrique CUP POINT A2 STAIN

- Page 360 and 361:

Metric Métrique FLAT POINT DIAMETE

- Page 362 and 363:

Metric Métrique STEEL Not Plated P

- Page 364 and 365:

Inch Pouces Threads BA - British As

- Page 366 and 367:

CATALOG 13 Inch Pouces See page B89

- Page 368 and 369:

Inch Pouces STEEL GRADE 5 NOT PLATE

- Page 370 and 371:

CATALOG 13 Metric Métrique METRIC

- Page 372 and 373:

Inch Pouce Steel ELEVATOR BOLTS Not

- Page 374 and 375:

Inch Pouce STEEL Plow Bolts No. 3 R

- Page 376 and 377:

Inch Pouce U-Bolts Boulons en U CAT

- Page 378 and 379:

Inch Pouce 304 STAINLESS STEEL EYE

- Page 380 and 381:

CATALOG 13 Metric Métrique Regular

- Page 382 and 383:

Inch Pouces Rod Ends with Bearings

- Page 384 and 385:

Inch Pouces STAINLESS STEEL WROUGHT

- Page 386 and 387:

Inch Pouces STAINLESS STEEL Type 30

- Page 388 and 389:

Inch Pouces HOOK Fitting Drop Forge

- Page 390 and 391:

Inch Pouces 18-8 STAINLESS STEEL TH

- Page 392 and 393:

Metric Métrique MALLEABLE IRON WIN

- Page 394 and 395:

CATALOG 13 Inch and Metric Pouces e

- Page 396 and 397:

B Threaded Rods Tiges filetées STE

- Page 398 and 399:

Threaded Rods Tiges filetées Inch

- Page 400 and 401:

Non-ferrousThreaded Rods Tiges file

- Page 402 and 403:

Threaded Rod Tiges filetées Metric

- Page 404 and 405:

Threaded Studs Goujons filetées In

- Page 406 and 407:

Tool Post Screws Vis pour étrier I

- Page 408 and 409:

B T-Slot & Flange Nuts Écrous et

- Page 410 and 411:

T-Slot Bolts & Nuts Boulons et écr

- Page 412 and 413:

Washers Rondelles Metric Métrique

- Page 414 and 415:

Nuts, Inserts & Internally Threaded

- Page 416 and 417:

Inch Pouces INCH CAP SCREW SIZES ST

- Page 418 and 419:

CATALOG 13 Inch Pouces COUPLING NUT

- Page 420 and 421:

Inch Pouces ASME/ANSI B18.2.2 CORRO

- Page 422 and 423:

Metric Métrique ISO Metric Propert

- Page 424 and 425:

Metric Métrique 10 ISO Metric Prop

- Page 426 and 427:

Metric Métrique HEXAGON LOW NUTS C

- Page 428 and 429:

Metric Métrique HEXAGON LOW NUTS C

- Page 430 and 431:

Metric Métrique Slotted Hexagon Nu

- Page 432 and 433:

Inch Pouces Slip-on ® Lock Nut Uni

- Page 434 and 435:

Metric Métrique Hexagon Nuts Écro

- Page 436 and 437:

Metric Métrique STEEL Metric Sizes

- Page 438 and 439:

Inch Pouces STEEL Cadmium Plated HU

- Page 440 and 441:

Inch and Metric Pouces et Métrique

- Page 442 and 443:

Inch Pouces Nylon Insert Hex Locknu

- Page 444 and 445:

Inch Pouces Hexagon Nuts Écrous he

- Page 446 and 447:

Metric Métrique NYLON INSERT HEX L

- Page 448 and 449:

Metric Métrique Nylon Insert Lockn

- Page 450 and 451:

Inch Pouces STEEL TOP DISTORTION, P

- Page 452 and 453:

Inch Pouces STEEL REGULAR FLANGE SI

- Page 454 and 455:

CATALOG 13 Inch and Metric Pouces e

- Page 456 and 457:

Inch Pouces LOCKING FEATURE F 45°

- Page 458 and 459:

Inch and Metric Pouces et Métrique

- Page 460 and 461:

Inch Pouces ®˜ Locknuts Écrous i

- Page 462 and 463:

Inch Pouces ® Weld Nuts Écrous à

- Page 464 and 465:

Inch and Metric Pouces et Métrique

- Page 466 and 467:

CATALOG 13 Inch and Metric Pouces e

- Page 468 and 469:

Inch Pouces Wing Nuts Écrous à or

- Page 470 and 471:

Metric Métrique Wing Nuts Écrous

- Page 472 and 473:

Inch and Metric Pouces et Métrique

- Page 474 and 475:

Metric Métrique METRIC - CAP and D

- Page 476 and 477:

Inch Pouces T-NUTS PLAIN STEEL Roun

- Page 478 and 479:

Inch and Metric Pouces et Métrique

- Page 480 and 481:

Inch Pouces CAPPED and SOLID ONE PI

- Page 482 and 483:

Inch Pouces ® Security Hardware Qu

- Page 484 and 485:

Inch Pouces Rapid Assembly Post and

- Page 486 and 487:

Tinnerman ® Section Index Index po

- Page 488 and 489:

CATALOG 13 Tel: 1-800-265-8772 Fax:

- Page 490 and 491:

Tinnerman ® brand fasteners Attach

- Page 492 and 493:

Inch Pouces Tinnerman ® brand fast

- Page 494 and 495:

Inch Pouces FLAT-TYPE and Zip-on Fi

- Page 496 and 497:

Inch Pouces J-TYPE Fasteners C X P

- Page 498 and 499:

Inch Pouces J-TYPE Fasteners C X P

- Page 500 and 501:

Inch Pouces U-TYPE Fasteners C X P

- Page 502 and 503:

Inch Pouces U-TYPE Fasteners C X P

- Page 504 and 505:

Inch Pouces U-TYPE Fasteners C X P

- Page 506 and 507:

Inch Pouces U-TYPE Fasteners C X P

- Page 508 and 509:

Inch Pouces U-TYPE Fasteners C X P

- Page 510 and 511:

Inch Pouces U-TYPE Fasteners (Speci

- Page 512 and 513:

Inch Pouces U-TYPE Fasteners (Speci

- Page 514 and 515:

Inch Pouces STANDARD NUT RETAINERS

- Page 516 and 517:

Inch Pouces STANDARD NUT RETAINERS

- Page 518 and 519:

Inch Pouces U-TYPE NUT RETAINERS A

- Page 520 and 521:

Inch Pouces PUSH-ON TYPE Fasteners

- Page 522 and 523:

Inch Pouces PUSH-ON TYPE Fasteners

- Page 524 and 525:

Inch Pouces PUSH-ON TYPE Fasteners

- Page 526 and 527:

Inch Pouces PUSH-ON TYPE Fasteners

- Page 528 and 529:

Inch Pouces PUSH-ON TYPE Fasteners

- Page 530 and 531:

Inch Pouces Tinnerman ® brand fast

- Page 532 and 533:

Inch Pouces TUBULAR TYPE Fasteners

- Page 534 and 535:

Inch Pouces TUBULAR TYPE Fasteners

- Page 536 and 537:

Inch Pouces DART TYPE Fasteners (Sp

- Page 538 and 539:

Inch Pouces U-TYPE Fasteners (Stand

- Page 540 and 541:

Inch Pouces SPECIAL PURPOSE Fastene

- Page 542 and 543:

Inch Pouces CABLE, WIRE, ROD & TUBE

- Page 544 and 545:

Inch Pouces CAP TYPE PUSH-ON Plasti

- Page 546 and 547:

Inch Pouces Tinnerman ® brand fast

- Page 548 and 549:

Metric Métrique Tinnerman ® brand

- Page 550 and 551:

Inch Pouces Spring Nuts Écrous à

- Page 552 and 553:

Inch and Metric Pouces et Métrique

- Page 554 and 555:

Push-On Hex Nuts Écrous hexagonale

- Page 556 and 557:

Inch and Metric Pouces et Métrique

- Page 558 and 559:

CATALOG 13 Inch Pouces Design 1 Des

- Page 560 and 561:

Inch and Metric Pouces et Métrique

- Page 562 and 563:

Inch Pouces Screw Anchors (Winged)

- Page 564 and 565:

Inch Pouces NYLON ANCHORS Use with

- Page 566 and 567:

CATALOG 13 Inch Pouces 1. Place #2

- Page 568 and 569:

CATALOG 13 Inch Pouces EXPANDET ®

- Page 570 and 571:

Inch Pouces RED HEAD WEDGE ANCHORS

- Page 572 and 573:

Metric Métrique Projection Bolt Ty

- Page 574 and 575:

Inch Pouce Bolt not included. ALLOY

- Page 576 and 577:

CATALOG 13 Inch Pouces ••• ad

- Page 578 and 579:

Inch Pouces Self-Clinching Nuts Sel

- Page 580 and 581:

Metric Métrique PEM ® Self-Clinch

- Page 582 and 583:

Inch and Metric Pouces et Métrique

- Page 584 and 585:

CATALOG 13 Inch and Metric Pouces e

- Page 586 and 587:

CATALOG 13 Inch and Metric Pouces e

- Page 588 and 589:

Inch and Metric Pouces et Métrique

- Page 590 and 591:

Inch and Metric Pouces et Métrique

- Page 592 and 593:

Inch and Metric Pouces et Métrique

- Page 594 and 595:

Inch and Metric Pouces et Métrique

- Page 596 and 597:

Inch and Metric AVK Industrial Prod

- Page 598 and 599:

Inch and Metric Pouces et Métrique

- Page 600 and 601:

Inch and Metric Pouces et Métrique

- Page 602 and 603:

CATALOG 13 Inch Pouces See chart on

- Page 604 and 605:

CATALOG 13 Inch Pouces See chart on

- Page 606 and 607:

CATALOG 13 Inch and Metric Pouces e

- Page 608 and 609:

Inch and Metric Pouces et Métrique

- Page 610 and 611:

Rivet Nut/Stud Power Tools Outils p

- Page 612 and 613:

C Fasteners Attaches Design 1 Screw

- Page 614 and 615:

Dodge ® Inserts Piéces filetées

- Page 616 and 617:

Barb-Sert ® «Barb-Sert ® » Inch

- Page 618 and 619:

C "E-Z Lok" Press Inserts Douilles

- Page 620 and 621:

C Rivet Nuts Écrous à Rivets Blin

- Page 622 and 623:

C Rivet Nut Header Tools Écrous Ri

- Page 624 and 625:

Rivet Nuts Écrous à Rivets Metric

- Page 626 and 627:

C Rivet Nut Header Tools Écrous no

- Page 628 and 629:

Inch and Metric Pouces et Métrique

- Page 630 and 631:

General Application Procedures Mode

- Page 632 and 633:

C Thread Repair Inserts Pièces fil

- Page 634 and 635:

C Thread Repair Inserts Pièces fil

- Page 636 and 637:

C Thread Repair Inserts Pièces fil

- Page 638 and 639:

C Thread Repair Inserts Pièces fil

- Page 640 and 641:

Thread Repair Inserts Pièces filet

- Page 642 and 643:

Washers Rondelles Flat Washers Rond

- Page 644 and 645:

Inch Pouces Steel Fender Washers Lo

- Page 646 and 647:

Inch Pouces cont'd. Additional Stee

- Page 648 and 649:

Inch Pouces “STANDARD” 316 Stai

- Page 650 and 651:

“STANDARD” SPAENAUR No. BOLT SI

- Page 652 and 653:

CATALOG 13 Inch Pouces SPAENAUR No.

- Page 654 and 655:

Metric Métrique ~DIN 125B ~ ISO 70

- Page 656 and 657:

CATALOG 13 Metric Métrique Metric

- Page 658 and 659:

Metric Métrique Metric Flat Washer

- Page 660 and 661:

Metric Métrique DIN 1440 ~ DIN EN

- Page 662 and 663:

Metric Métrique Sealing Rings Anne

- Page 664 and 665:

Inch Pouces Stainless - Aluminum -

- Page 666 and 667:

Metric Métrique Spring (Split) Loc

- Page 668 and 669:

Metric Métrique Spring (Split) Loc

- Page 670 and 671:

Metric Métrique Spring (Split) Loc

- Page 672 and 673:

Inch Pouces ASSORTMENT ASSORTIMENT

- Page 674 and 675:

Metric Métrique METRIC STYLES DIN

- Page 676 and 677:

Metric Métrique Tooth Lockwasher A

- Page 678 and 679:

VIBRATION PROOF FASTENERS R Data Sh

- Page 680 and 681:

Inch and Metric Pouces et Métrique

- Page 682 and 683:

Predictable performance for rated l

- Page 684 and 685:

INTRODUCTION TO COST-SAVING, SPACE-

- Page 686 and 687:

Dynamic Loading & Fatigue Life Dyna

- Page 688 and 689:

CATALOG 13 The tolerances shown on

- Page 690 and 691:

CATALOG 13 Nominal Dia. Bolt stress

- Page 692 and 693:

CATALOG 13 Inch Pouces …Continued

- Page 694 and 695:

CATALOG 13 Inch Pouces AK Series FO

- Page 696 and 697:

CATALOG 13 Metric Métrique Priced

- Page 698 and 699:

Metric Métrique NOMENCLATURE P = l

- Page 700 and 701:

Metric Métrique NOMENCLATURE P = l

- Page 702 and 703:

Metric Métrique NOMENCLATURE P = l

- Page 704 and 705:

Metric Métrique NOMENCLATURE P = l

- Page 706 and 707:

Inch Pouces LIVE LOAD FLANGE AND GA

- Page 708 and 709:

Inch Pouces WAVE SPRING TENSION WAS

- Page 710 and 711:

Metric Métrique Spring Tension Was

- Page 712 and 713:

Inch Pouce Rubber Washers Rondelles

- Page 714 and 715:

CATALOG 13 Inch Pouce NYLTITE ROLLE

- Page 716 and 717:

CATALOG 13 Inch Pouce Material: 6/6

- Page 718 and 719:

Inch and Metric Pouce et Métrique

- Page 720 and 721:

Inch Pouce SHIM RINGS WITH KEYWAY S

- Page 722 and 723:

CATALOG 13 Inch Pouce BLUE TEMPERED

- Page 724 and 725:

Inch Pouce Steel - Zinc Plated Unit

- Page 726 and 727:

Inch Pouce Steel - Zinc Plated Unit

- Page 728 and 729:

Inch Pouce ALIGNING SHIMS FOR START

- Page 730 and 731:

Solid Steel Rivets Rivets pleins en

- Page 732 and 733:

Solid Aluminum Rivets Rivets solide

- Page 734 and 735:

Solid Tinners’ Rivets Rivets soli

- Page 736 and 737:

Steel Shallow Tubular Rivets Rivets

- Page 738 and 739:

Steel Tubular Rivets Rivets tubulai

- Page 740 and 741:

E Steel Tubular Rivets Rivets tubul

- Page 742 and 743:

E Split Rivets Rivets fendu Split R

- Page 744 and 745:

Shallow Tubular Rivets Rivets tubul

- Page 746 and 747:

Pop ® Rivets Rivets «Pop ® » AL

- Page 748 and 749:

Pop ® Rivets Rivets «Pop ® » AL

- Page 750 and 751:

E Pop ® Rivets Rivets «Pop ® »

- Page 752 and 753:

Inch Pouces STEEL Dome Head Open-en

- Page 754 and 755:

Inch Pouces Pop ® Rivets Rivets «

- Page 756 and 757:

Inch Pouces Priced Singly ASSORTMEN

- Page 758 and 759:

CATALOG 13 Inch Pouces POP ® 5000

- Page 760 and 761:

Inch Pouces 'POP' PowerLink 30 A Re

- Page 762 and 763:

Inch Pouces 360° Swivel Head SPAEN

- Page 764 and 765:

Inch Pouces Structural — Self-plu

- Page 766 and 767:

Inch Pouces “Cherry” Rivet Pull

- Page 768 and 769:

CATALOG 13 Inch Pouces Nominal SPAE

- Page 770 and 771:

Inch Pouces ALUMINUM UNIT G L PACKA

- Page 772 and 773:

Inch Pouces UNIT PACKAGE 500 RIVETS

- Page 774 and 775:

Inch Pouces Nylon Drive Rivets High

- Page 776 and 777:

Inch Pouces Cotter Pins Goupilles f

- Page 778 and 779:

We source from 1,200 domestic and i

- Page 780 and 781:

Metric Métrique Metric Cotter Pins

- Page 782 and 783:

Metric Métrique Metric Cotter Pins

- Page 784 and 785:

Inch Pouces Hitch Pin Clips Agrafes

- Page 786 and 787:

Inch Pouces Hitch Pin Clips Agrafes

- Page 788 and 789:

Metric Métrique Hitch Pin Clips Ag

- Page 790 and 791:

Metric Métrique 301/302 Stainless

- Page 792 and 793:

Metric Métrique Metric Type B Spri

- Page 794 and 795:

Inch Pouces Hair Pin Cotters Goupil

- Page 796 and 797:

Inch Pouces Hitch Pin Clips Agrafes

- Page 798 and 799:

Inch Pouces FAST-POSITIVE SAFETY LO

- Page 800 and 801:

Inch and Metric Pouces et Métrique

- Page 802 and 803:

Metric Métrique Safety Lynch Pins

- Page 804 and 805:

CATALOG 13 Metric Métrique Lynch P

- Page 806 and 807:

Inch Pouces C D B E STYLE A to 7/16

- Page 808 and 809:

CATALOG 13 Inch Pouces STEEL Materi

- Page 810 and 811:

Inch Pouces Quick Release Pins Quic

- Page 812 and 813:

Inch Pouces C-1008/C-1018 Grade STE

- Page 814 and 815:

Inch Pouces 300 Series STAINLESS ST

- Page 816 and 817:

Inch Pouces P.C. 699 STEEL DROP FOR

- Page 818 and 819:

Inch and Metric Pouces et Métrique

- Page 820 and 821:

Metric Métrique Dowel Pins Goupill

- Page 822 and 823:

Metric Métrique Dowel Pins Goupill

- Page 824 and 825:

Inch Pouces Taper Pins Goupilles co

- Page 826 and 827:

Taper Pins Goupilles coniques Metri

- Page 828 and 829:

Taper Pins Goupilles coniques Metri

- Page 830 and 831:

Dowel Pins Goupilles cylindriques M

- Page 832 and 833:

Spring Tension Pins Goupilles tende

- Page 834 and 835:

Spring Tension Pins Goupilles tende

- Page 836 and 837:

Spring Tension Pins Goupilles tende

- Page 838 and 839:

Coiled Spring Pins Goupilles à res

- Page 840 and 841:

Coiled Spring Pins Goupilles à res

- Page 842 and 843:

Coiled Spring Pins Goupilles à res

- Page 844 and 845:

E Woodruff Keys Clavettes «Woodruf

- Page 846 and 847:

E Shaft Keys Clés d’arbre SHAFT

- Page 848 and 849:

Machine Key Stock Barres à clés R

- Page 850 and 851:

E Drill Rod Rounds Acier en rondin

- Page 852 and 853:

Steel Rounds Barres rondes STEEL CO

- Page 854 and 855:

E Shaft Collars and Couplings Annea

- Page 856 and 857:

Internal - Retaining Rings - Extern

- Page 858 and 859:

Internal - Retaining Rings - Extern

- Page 860 and 861:

E Retaining Rings - External Bagues

- Page 862 and 863:

E Retaining Rings - Internal Bagues

- Page 864 and 865:

E Retaining Rings - External Bagues

- Page 866 and 867:

E Retaining Rings - External Bagues

- Page 868 and 869:

E Retaining Rings - Internal Bagues

- Page 870 and 871:

Internal - Retaining Rings - Extern

- Page 872 and 873:

Inch Pouces Crimp-on Retainers Bagu

- Page 874 and 875:

Metric Métrique DIN 6799 Retaining

- Page 876 and 877:

CATALOG 13 Inch Pouces PLIERS for I

- Page 878 and 879:

Inch Pouces Retaining Ring Tools Ou

- Page 880 and 881:

F Furniture Glides Patins pour pied

- Page 882 and 883:

Furniture Glides Patins pour pieds

- Page 884 and 885:

Leg Levelers Patins pour pieds de m

- Page 886 and 887:

Furniture Glides Patins pour pieds

- Page 888 and 889:

Thread Adapters Adaptateurs de file

- Page 890 and 891:

F Furniture Glides Patins pour pied

- Page 892 and 893:

Corrugated Fasteners / Mending Plat

- Page 894 and 895:

F Catches / Swivel Plates Fermeture

- Page 896 and 897:

Clips & Hangers, Etc. Pinces & croc

- Page 898 and 899:

Hose, Tube and Wiring Components Co

- Page 900 and 901:

Inch Pouces LS: 9/16" (14 mm) wide

- Page 902 and 903:

Metric Métrique ® Heavy Duty Hose

- Page 904 and 905:

Metric Métrique Hose Clamps Collie

- Page 906 and 907:

Inch Pouces ASSORTMENT ASSORTIMENT

- Page 908 and 909:

Inch Pouces 2-EAR CLAMP ASSORTMENTS

- Page 910 and 911:

Inch Pouces SPRING-GRIP HOSE CLAMPS

- Page 912 and 913:

Inch Pouces Colour: Natural, Clear

- Page 914 and 915:

Inch Pouces Miniature Nylon Fitting

- Page 916 and 917:

Inch Pouces Miniature Barbed Tees D

- Page 918 and 919:

Inch Pouces QUICK DISCONNECT LUER F

- Page 920 and 921:

Inch Pouces C-973 White Nylon HOSE

- Page 922 and 923:

Inch Pouces Locking Cable Ties Coll

- Page 924 and 925:

Inch Pouces Tubing & Wiring Fastene

- Page 926 and 927:

Inch Pouces Tubing & Wiring Fastene

- Page 928 and 929:

Inch Pouces Lightweight - Insulated

- Page 930 and 931:

Inch Pouces “HALF” CLIPS W Tubi

- Page 932 and 933:

Inch Pouces T-CLIPS Fastening Syste

- Page 934 and 935:

Inch Pouces TM Braided Expandable S

- Page 936 and 937:

CATALOG 13 Metric Métrique ASSORTM

- Page 938 and 939:

Inch Pouces Steel ROUND STEEL SPACE

- Page 940 and 941:

Inch Pouces NYLON 6/6 Printed Circu

- Page 942 and 943:

Metric Métrique METRIC Threaded He

- Page 944 and 945:

CATALOG 13 Metric Métrique Steel /

- Page 946 and 947:

Solderless and Soldering Terminals

- Page 948 and 949:

Insulated Solderless Terminals Born

- Page 950 and 951:

Insulated Solderless Terminals Coss

- Page 952 and 953:

Solderless Terminals Cosses sans so

- Page 954 and 955:

Assortments / Tools Assortiments /

- Page 956 and 957:

G Heat Shrink Connectors Connecteur

- Page 958 and 959:

Battery Terminals Terminaux de Batt

- Page 960 and 961:

Wiring Lugs & Splices Ergots et Ép

- Page 962 and 963:

G Connector Housings .093"/.062" Lo

- Page 964 and 965:

.062" (1,58 mm) Connector Housings

- Page 966 and 967:

.093" 2,36 mm Connector Housings Lo

- Page 968 and 969:

KK ® Modular Interconnecting Syste

- Page 970 and 971:

For the Electronics Engineer! Pour

- Page 972 and 973:

For the Electronics Engineer! Pour

- Page 974 and 975:

Fittings, Springs and Auto Trim Har

- Page 976 and 977:

Inch Pouces Plug Buttons Bouchons F

- Page 978 and 979:

Inch Pouces High Thrust Air Nozzles

- Page 980 and 981:

Inch Pouces STRAIGHT THREAD MAGNETI

- Page 982 and 983:

Metric Métrique DIN 906 Hexagon So

- Page 984 and 985:

Inch Pouces HEX. 5/8" 1/4" All Fitt

- Page 986 and 987:

Inch Pouces STAINLESS STEEL INCH Gr

- Page 988 and 989:

Metric Métrique M1 LUBRICATING NIP

- Page 990 and 991:

Inch Pouces STEEL INCH Sizes See Pa

- Page 992 and 993:

Inch Pouces Utility Spring Assortme

- Page 994 and 995:

CATALOG 13 Inch Pouces *Sizes avail

- Page 996 and 997:

Inch Pouces Moulding Fasteners Atta

- Page 998 and 999:

Inch Pouces Moulding Fasteners Atta

- Page 1000 and 1001:

Inch Pouces " MB-81 (4728594) 1 "

- Page 1002 and 1003:

Inch Pouces Clips & Fasteners Pince

- Page 1004 and 1005:

Inch Pouces THROTTLE ROD CLIPS Clip

- Page 1006 and 1007:

Inch Pouces Auto Glass Shop Items A

- Page 1008 and 1009:

Inch Pouces C-1089 Windshield Revea

- Page 1010 and 1011:

Inch Pouces Headlight Adjusting Scr

- Page 1012 and 1013:

Inch Pouces Headlamp Screws, etc. -

- Page 1014 and 1015:

Inch Pouces NYLON - License Fastene

- Page 1016 and 1017:

Inch Pouces FLEXIBLE CLEAR “VINYL

- Page 1018 and 1019:

Nylon 6/6 Hole Plugs Bouchons insta

- Page 1020 and 1021:

Anti-Vibration Mounts Amortisseurs

- Page 1022 and 1023:

J Anti-Vibration Mounts Amortisseur

- Page 1024 and 1025:

Bolt-on Vibration Mounts and Bumper

- Page 1026 and 1027:

Anti-Vibration Mounts Amortisseurs

- Page 1028 and 1029:

J Anti-Vibration Mounts Amortisseur

- Page 1030 and 1031:

Anti-Vibration Mounts Amortisseurs

- Page 1032 and 1033:

Anti-Vibration Mounts Amortisseurs

- Page 1034 and 1035:

Anti-vibration Leveling Mounts Amor

- Page 1036 and 1037:

Anti-vibration Leveling Mounts Amor

- Page 1038 and 1039:

Anti-Vibration Mounts Amortisseurs

- Page 1040 and 1041:

Anti-Vibration Mounts Amortisseurs

- Page 1042 and 1043:

Anti-Vibration Mounts Amortisseurs

- Page 1044 and 1045:

Tube Caps Chapeaux de tubes Inch Po

- Page 1046 and 1047:

Tube Caps Chapeaux de tubes Inch Po

- Page 1048 and 1049:

J Tapered Caps & Plugs Chapeaux et

- Page 1050 and 1051:

Pull Plugs Bouchons à tirette Inch

- Page 1052 and 1053:

Snap-In Plugs Type 1 & 2 Bouchons i

- Page 1054 and 1055:

J Nylon Plug Buttons Bouchons en ny

- Page 1056 and 1057:

Standard Threaded Caps Capuchons no

- Page 1058 and 1059:

Threaded Pipe Plugs Bouchons filet

- Page 1060 and 1061:

J Decorative Screw Cover Caps Capuc

- Page 1062 and 1063:

Mushroom and Stem Bumpers Butoirs t

- Page 1064 and 1065:

Rubber Bumpers — General Purpose

- Page 1066 and 1067:

Plug Bumpers Butoirs bouchons Mater

- Page 1068 and 1069:

Plug Bumpers Butoirs bouchons Inch

- Page 1070 and 1071:

Rubber Bumpers Boutoirs en caoutcho

- Page 1072 and 1073:

J Crutch, Stool and Furniture Tips

- Page 1074 and 1075:

Rubber Washers Rondelles en Caoutch

- Page 1076 and 1077:

Inch Pouces Material: Hardness: Col

- Page 1078 and 1079:

CATALOG 13 Inch Pouces " " " " C B

- Page 1080 and 1081:

Inch Pouces Bell-Mouth Nylon Strain

- Page 1082 and 1083:

Inch and Metric Pouces et Métrique

- Page 1084 and 1085:

Inch Pouces Material: SBR unless ot

- Page 1086 and 1087:

CATALOG 13 Inch Pouces …Continued

- Page 1088 and 1089:

Inch Pouces Miscellaneous Rubber It

- Page 1090 and 1091:

Inch Pouces Plastic Knobs Boutons e

- Page 1092 and 1093:

Inch Pouces Plastic Knobs Boutons e

- Page 1094 and 1095:

Inch Pouces Plastic Knobs Boutons e

- Page 1096 and 1097:

Inch Pouces Plastic Handles Poigné

- Page 1098 and 1099:

Inch Pouces Plastic Handles Poingé

- Page 1100 and 1101:

a C L H Inch Pouces CRANK HANDLE Fe

- Page 1102 and 1103:

J Plastic Knobs Boutons en plastiqu

- Page 1104 and 1105:

O-Ring Seals Joints toriques «O-Ri

- Page 1106 and 1107:

O-Ring Seals Joints toriques «O-Ri

- Page 1108 and 1109:

O-Ring Seals of Viton Joints toriqu

- Page 1110 and 1111:

J O-Ring Seals Joints toriques «O-

- Page 1112 and 1113:

O-Ring Seals Joints toriques «O-Ri

- Page 1114 and 1115:

Rubber and Plastic Extrusions Extru

- Page 1116 and 1117:

Inch Pouce Extruded Channels Canaux

- Page 1118 and 1119:

Inch Pouce "WEDGE-TITE" WEDGE INSER

- Page 1120 and 1121:

Inch Pouce Extruded Special Shapes

- Page 1122 and 1123:

Inch Pouce Extruded Special Shapes

- Page 1124 and 1125:

Inch Pouce Door Seals Collants (por

- Page 1126 and 1127:

Inch Pouce DUAL DUROMETER SPONGE AN

- Page 1128 and 1129:

Inch Pouce Trim Bordures QUICKEDGE

- Page 1130 and 1131:

Inch Pouce Flexible Weatherstrips B

- Page 1132 and 1133: Inch Pouce Channel Lining and Weath

- Page 1134 and 1135: Inch Pouce Substance & Structure Th

- Page 1136 and 1137: Inch Pouce STICKER-TITE Self-Sealin

- Page 1138 and 1139: Inch Pouce P.V.C. “SEAL-KING” (

- Page 1140 and 1141: Inch Pouces Wrap ® ’n Seal Indus

- Page 1142 and 1143: Inch Pouces Auto Glass Shop Items A

- Page 1144 and 1145: Inch Pouces Auto Glass Shop Items A

- Page 1146 and 1147: Inch Pouces VINYL SOFT-FOOT ANTI-F

- Page 1148 and 1149: Inch Pouces L U X U R F O A M “LU

- Page 1150 and 1151: Multi-Purpose Handles & Locks Poign

- Page 1152 and 1153: Multi-Purpose Handles & Locks Poign

- Page 1154 and 1155: L Multi-Purpose Handles & Locks Poi

- Page 1156 and 1157: Universal Door Handles Poignées de

- Page 1158 and 1159: Multi-Purpose Handles & Locks Poign

- Page 1160 and 1161: Multi-Purpose Handles & Locks Poign

- Page 1162 and 1163: Quarter-Turn Cabinet Latches Poign

- Page 1164 and 1165: Multi-Purpose Handles and Locks Poi

- Page 1166 and 1167: Catches Loquets MAGNETIC CATCH and

- Page 1168 and 1169: Clamp Fasteners Agrafes à bascule

- Page 1170 and 1171: Clamp Fasteners Agrafes à bascule

- Page 1172 and 1173: Clamp Fasteners Agrafes à bascule

- Page 1174 and 1175: Clamp Fasteners Agrafes à bascule

- Page 1176 and 1177: Clamp Fasteners Agrafes à bascule

- Page 1178 and 1179: Clamp Fasteners Agrafes à bascule

- Page 1180 and 1181: Clamp Fasteners Agrafes à bascule

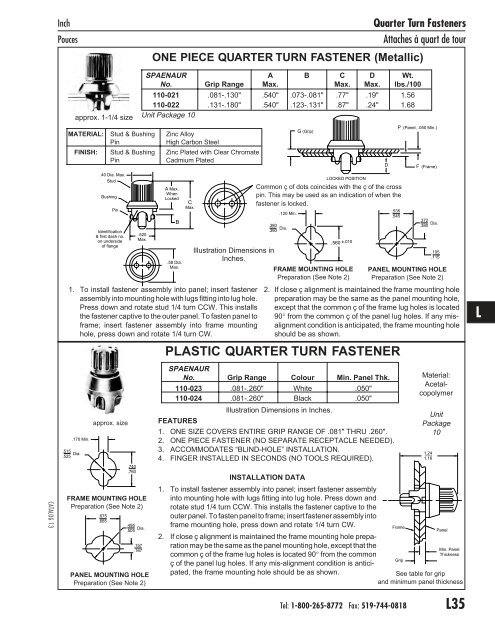

- Page 1184 and 1185: 50F Quarter Turn Fastener Attache

- Page 1186 and 1187: L Quarter Turn Fasteners Attaches

- Page 1188 and 1189: Quarter Turn Fasteners Attaches à

- Page 1190 and 1191: Door Hardware Items Articles de qui

- Page 1192 and 1193: Door Hardware Items Articles de qui

- Page 1194 and 1195: Door Hardware Items Articles de qui

- Page 1196 and 1197: L Multi-Purpose Handles & Cams Poig

- Page 1198 and 1199: Padlockable Handle Poignée verroui

- Page 1200 and 1201: Door Hardware Quincaillerie pour le

- Page 1202 and 1203: L Door Hardware Items Articles de q

- Page 1204 and 1205: Latches Loquets ® Inch Pouces SLEE

- Page 1206 and 1207: Latches Loquets Push Latch ® Inch

- Page 1208 and 1209: Latches Loquets Inch Pouces This st

- Page 1210 and 1211: Slam Latches Cliquets à claquer Fl

- Page 1212 and 1213: Slam Latches Cliquets à claquer In

- Page 1214 and 1215: Slam Latches Cliquets à claquer Ba

- Page 1216 and 1217: Slam Latches Cliquets à claquer Th

- Page 1218 and 1219: Cab Door Hardware Quincaillerie pou

- Page 1220 and 1221: Cab Door Hardware Quincaillerie pou

- Page 1222 and 1223: Flush-Mounted Paddle Handle Latches

- Page 1224 and 1225: L Van Door Hardware Quincaillerie p

- Page 1226 and 1227: Van Door Hardware Quincaillerie pou

- Page 1228 and 1229: L Van Door Hardware Quincaillerie p

- Page 1230 and 1231: Door Hardware Items Articles de qui

- Page 1232 and 1233:

Door Hardware Items Articles de qui

- Page 1234 and 1235:

Van Door Hardware Quincaillerie pou

- Page 1236 and 1237:

Van Hardware Quincaillerie pour fou

- Page 1238 and 1239:

Folding Seat Brackets and Step Appu

- Page 1240 and 1241:

Van Hardware Qunicaillerie pour fou

- Page 1242 and 1243:

"Reach-in" Refrigerator Locks Serru

- Page 1244 and 1245:

Van Door Hardware Quincaillerie pou

- Page 1246 and 1247:

L Van Door Hardware Quincaillerie p

- Page 1248 and 1249:

Cam Lift Hinges Pentures de relevag

- Page 1250 and 1251:

Strap Hinges Pentures en acier HEAV

- Page 1252 and 1253:

Steel Strap Hinges Pentures en acie

- Page 1254 and 1255:

Steel Hinges Charnières en acier I

- Page 1256 and 1257:

Steel Hinges Charnières en acier D

- Page 1258 and 1259:

Plastic Hinges Charnières en plast

- Page 1260 and 1261:

Hinges Charnières 2-29/32" (74 mm)

- Page 1262 and 1263:

L Continuous Hinges Charnières con

- Page 1264 and 1265:

Hinges Charnières Inch Pouces Hing

- Page 1266 and 1267:

Hood Clamps Attache-capots NOTE: De

- Page 1268 and 1269:

Hood Fastener Straps Attaches à sa

- Page 1270 and 1271:

We Are Proud To Represent …the Le

- Page 1272 and 1273:

Adjustable Grip Latches Cliquets à

- Page 1274 and 1275:

T-handle Latch Mid-size series 10

- Page 1276 and 1277:

INSTALLATION FOR SPRING COMPRESSION

- Page 1278 and 1279:

CATALOG 13 Single-hole Mount Large

- Page 1280 and 1281:

Lift and Turn ® Latches Cliquets

- Page 1282 and 1283:

Flush Sealed Latch • Use in NEMA-

- Page 1284 and 1285:

Grabber Door Catch Mounts inside yo

- Page 1286 and 1287:

CATALOG 13 Slam-action Keylatch-in

- Page 1288 and 1289:

Paddle Latches Miniature Size • I

- Page 1290 and 1291:

; ; ;;; CATALOG 13 Pocket Pull ® F

- Page 1292 and 1293:

CATALOG 13 Concealed Pulls • A pu

- Page 1294 and 1295:

Dual Lock ® Butt-Joint Panel Latch

- Page 1296 and 1297:

;;; Soft Latch ® Draw Latch • Al

- Page 1298 and 1299:

Over-centre Draw Latch Assembly - S

- Page 1300 and 1301:

Versa Latch ® Tension Latch Small

- Page 1302 and 1303:

Adjustable Draw Latch Multiple size

- Page 1304 and 1305:

~~UTHCd Designer Series Draw Latch

- Page 1306 and 1307:

Draw Latches Cliquets d'attelage 10

- Page 1308 and 1309:

Link Lock ® Rotary Action Latch La

- Page 1310 and 1311:

Link Lock ® Rotary Action Latch Sm

- Page 1312 and 1313:

Concealed Hinges… Provide good lo

- Page 1314 and 1315:

CATALOG 13 Metal Lift-Off Hinges

- Page 1316 and 1317:

Friction Adjustable Hinges For free

- Page 1318 and 1319:

Swell Latches Heavy Duty Version

- Page 1320 and 1321:

Swell Action Latches • Latches in

- Page 1322 and 1323:

Series 82 Selection Guide To select

- Page 1324 and 1325:

Series 82 Sealing Washer Cupped Qua

- Page 1326 and 1327:

Quarter Turn Fasteners Attaches à

- Page 1328 and 1329:

Spring Loaded Plunger • Provides

- Page 1330 and 1331:

VELCRO ® Fasteners Attaches «VELC

- Page 1332 and 1333:

VELCRO ® Fasteners Attaches «VELC

- Page 1334 and 1335:

VELCRO ® Fasteners Attaches «VELC

- Page 1336 and 1337:

VELCRO ® Buckles and Hardware Bouc

- Page 1338 and 1339:

VELCRO ® Buckles and Hardware Bouc

- Page 1340 and 1341:

M Slide Fasteners Fermetures à gli

- Page 1342 and 1343:

Bungee Cords Corde élastique Inch

- Page 1344 and 1345:

Elastic Cable / TowStraps and Rope

- Page 1346 and 1347:

M Hardware - for Shockcord, etc. Qu

- Page 1348 and 1349:

Rubber Tie-downs Fixations en caout

- Page 1350 and 1351:

Tie-Downs Fixations PROTECT YOUR IN

- Page 1352 and 1353:

Inch Pouces SYNTHETIC ROPE IN HANDY

- Page 1354 and 1355:

Inch Pouces Needles, etc. Aiguilles

- Page 1356 and 1357:

Inch and Metric Pouces et Métrique

- Page 1358 and 1359:

Metric Métrique Delrin 500 Strap B

- Page 1360 and 1361:

Metric Métrique Metric Self-lockin

- Page 1362 and 1363:

Metric Métrique Metric SNAP CATCH

- Page 1364 and 1365:

Inch Pouces Plastic Buckles & Faste

- Page 1366 and 1367:

Inch Pouces SNAP FASTENERS Flanged

- Page 1368 and 1369:

Inch Pouces Fastener Tools Outils d

- Page 1370 and 1371:

Inch Pouce Fabric & Leather Fastene

- Page 1372 and 1373:

CATALOG 13 Inch Pouce SHEET BRASS G

- Page 1374 and 1375:

M Standardized Brass Eyelets Oeille

- Page 1376 and 1377:

Upholsterers’ Tools Outils de tap

- Page 1378 and 1379:

Upholsters’ Tools Outils de tapis

- Page 1380 and 1381:

Upholstery Tufting Buttons Boutons,

- Page 1382 and 1383:

Cushion Springs and Clips Ressorts

- Page 1384 and 1385:

Decorative Upholstery Nails Clous d

- Page 1386 and 1387:

Stainless Steel Nails Clous en acie

- Page 1388 and 1389:

Metal Rings Anneaux métalliques SP

- Page 1390 and 1391:

M Metal “Dee” Rings and Clips A

- Page 1392 and 1393:

M Hardware Miscellaneous Quincaille

- Page 1394 and 1395:

Snaps, Hooks, etc. Mousquetons, cro

- Page 1396 and 1397:

Buckles, Snaps, Hooks, etc. Boucles

- Page 1398 and 1399:

Wire Rope Clips, Clamps, Thimbles a

- Page 1400 and 1401:

Wire Rope Câble métallique Inch P

- Page 1402 and 1403:

Inch Pouces Grade 30 Clevis Slip Ho

- Page 1404 and 1405:

Quick Connecting Links Maillon à b

- Page 1406 and 1407:

Plastic Chain and Attachments Chaî

- Page 1408 and 1409:

Hazet ® Tools Outils Hazet ® Nut

- Page 1410 and 1411:

® Hex Nut-Drivers Functional dimen

- Page 1412 and 1413:

® Double Open-End Wrenches ISO 108

- Page 1414 and 1415:

® Combination Box and Open-End Wre

- Page 1416 and 1417:

® Double-Hex Box Wrenches DIN 897,

- Page 1418 and 1419:

® Flat Chisels Chrome-Vanadium Mat

- Page 1420 and 1421:

® Grip Pliers Especially designed

- Page 1422 and 1423:

® Pullers Special Steel Galvanized

- Page 1424 and 1425:

® Offset Screwdrivers DIN 5200 Chr

- Page 1426 and 1427:

® Screwdrivers For Slotted Screws

- Page 1428 and 1429:

® Stud Extractors Chrome-Vanadium

- Page 1430 and 1431:

® Hex Socket Chrome-Vanadium 1/4"

- Page 1432 and 1433:

® 167 x 97 x 37 mm 1/4" Socket Set

- Page 1434 and 1435:

® 6 Point Sockets 3/8 inch 6 Point

- Page 1436 and 1437:

® Phillips Socket Sockets Chrome-V

- Page 1438 and 1439:

® 3/8 inch 344 x 188 x 56 mm 6 Poi

- Page 1440 and 1441:

® 6 Point Sockets DIN 3124, ISO 27

- Page 1442 and 1443:

® Speeder DIN 3122, ISO 3315 Chrom

- Page 1444 and 1445:

® Spark Plug Socket with Universal

- Page 1446 and 1447:

® XZN Sockets 1/2 inch Sockets Chr

- Page 1448 and 1449:

® 320 x 128 x 58 mm Hex Sockets 1/

- Page 1450 and 1451:

® Ratchet Head Chrome-Vanadium 3/4

- Page 1452 and 1453:

® Extensions DIN 3123, ISO 3316 Ch

- Page 1454 and 1455:

® Diagonal Cutters Special Steel F

- Page 1456 and 1457:

® Lockring Pliers Spring Steel Rev

- Page 1458 and 1459:

® Automatic Wire Stripper For soli

- Page 1460 and 1461:

® Ball Peen Hammers Chrome-Vanadiu

- Page 1462 and 1463:

® Hex Head Wrench Set DIN 911, ISO

- Page 1464 and 1465:

® Screwdriver Bits Screwdriver Bit

- Page 1466 and 1467:

® CATALOG 13 Adapters Chrome-Vanad

- Page 1468 and 1469:

® Standard Torque Wrench SYSTEM 50

- Page 1470 and 1471:

® Trimming Knife (protected by des

- Page 1472 and 1473:

Hand Tools Outils portatifs Allen

- Page 1474 and 1475:

Inch and Metric Pouces et Métrique

- Page 1476 and 1477:

Inch and Metric Pouces et Métrique

- Page 1478 and 1479:

CATALOG 13 Inch Pouces KEY FIT TABL

- Page 1480 and 1481:

Metric Métrique HEX KEYS Metric DI

- Page 1482 and 1483:

Metric Métrique DIN 911 METRIC HEX

- Page 1484 and 1485:

Inch Pouces Key Wrenches of ALLOY S

- Page 1486 and 1487:

Eliminator Socket Sets «Eliminator

- Page 1488 and 1489:

Eliminator Socket Sets «Eliminator

- Page 1490 and 1491:

Eliminator Socket Sets «Eliminator

- Page 1492 and 1493:

Torque Wrenchs Clefs á torsion Inc

- Page 1494 and 1495:

Socket Sets Ensembles de douilles S

- Page 1496 and 1497:

Socket Sets Ensembles de douilles M

- Page 1498 and 1499:

Socket Sets Ensembles de douilles S

- Page 1500 and 1501:

Super Palmster «Super Palmster» S

- Page 1502 and 1503:

P Hex Bits Mèches hexagonales Inse

- Page 1504 and 1505:

TORX ® DRIVE Bits Mèches «TORX

- Page 1506 and 1507:

Screwdrivers Tournevis Inch Pouces

- Page 1508 and 1509:

Insert Bit Kit Trousse d'embouts In

- Page 1510 and 1511:

Screwdrivers Tournevis A wide range

- Page 1512 and 1513:

Screwdrivers Tournevis Screwdriver

- Page 1514 and 1515:

Uni-Driver ® «Uni-Driver ® » RA

- Page 1516 and 1517:

P Straight Shank Jobbers’ Drills

- Page 1518 and 1519:

High Speed Drills Forets rapides en

- Page 1520 and 1521:

P Rotary Masonry Drill Forets rotat

- Page 1522 and 1523:

Countersinks Fraises Countersinks y

- Page 1524 and 1525:

High Speed Straight Shank Jobbers

- Page 1526 and 1527:

Jobbers’ Straight Shank Twist Dri

- Page 1528 and 1529:

Twist Drills For Wood Forets hélic

- Page 1530 and 1531:

Extra Long Twist Drills Forets extr

- Page 1532 and 1533:

Twist Drills With Morse Taper Shank

- Page 1534 and 1535:

Masonry Drills Forets pour maçonne

- Page 1536 and 1537:

Precisions - Countersinks Fraise de

- Page 1538 and 1539:

Milling Cutters Fraises Metric Mét

- Page 1540 and 1541:

Reamers Alésoirs Metric Métrique

- Page 1542 and 1543:

Reamers Alésoirs Metric Métrique

- Page 1544 and 1545:

Reamers Alésoirs METRIC QUICK ACTI

- Page 1546 and 1547:

CATALOG 13 STD. SET TYPE 0420 Taper

- Page 1548 and 1549:

Inch Pouces Tap Terminology Termino

- Page 1550 and 1551:

CATALOG 13 Inch Pouces TAPS HIGH SP

- Page 1552 and 1553:

Inch and Metric Pouces et Métrique

- Page 1554 and 1555:

Metric Métrique STRAIGHT FLUTE MET

- Page 1556 and 1557:

Metric Métrique STRAIGHT FLUTE MET

- Page 1558 and 1559:

Metric Métrique Hand or Machine Ta

- Page 1560 and 1561:

Inch Pouces Pipe Taps and Dies Tara

- Page 1562 and 1563:

Metric Métrique Round Dies Écrous

- Page 1564 and 1565:

Metric Métrique METRIC FINE THREAD

- Page 1566 and 1567:

CATALOG 13 Metric Métrique METRIC

- Page 1568 and 1569:

Inch and Metric Pouce et Métrique

- Page 1570 and 1571:

Inch and Metric Pouce et Métrique

- Page 1572 and 1573:

Inch and Metric Pouce et Métrique

- Page 1574 and 1575:

Inch Pouce Feeler Gauges Jauges d'

- Page 1576 and 1577:

Inch and Metric Pouce et Métrique

- Page 1578 and 1579:

Inch Pouce Measuring Devices Dispos

- Page 1580 and 1581:

Inch and Metric Pouces et Métrique

- Page 1582 and 1583:

Inch and Metric Pouces et Métrique

- Page 1584 and 1585:

Metric Métrique Adjustable Spanner

- Page 1586 and 1587:

CATALOG 13 Metric Métrique DIN 181

- Page 1588 and 1589:

CATALOG 13 Metric Métrique A/F SPA

- Page 1590 and 1591:

Inch Pouces Box Wrenches 12 Point,

- Page 1592 and 1593:

CATALOG 13 Inch and Metric Pouces e

- Page 1594 and 1595:

Inch Pouces Identification Tools Ou

- Page 1596 and 1597:

CATALOG 13 Inch Pouces A WHOLE TOOL

- Page 1598 and 1599:

Inch Pouces Locking "C" Clamps Brid

- Page 1600 and 1601:

Inch Pouce SPAENAUR No. 876-381 Hea

- Page 1602 and 1603:

Inch Pouces Toggle Action Clamps Ag

- Page 1604 and 1605:

Inch Pouces RED HEAD PUSH-PULL TYPE

- Page 1606 and 1607:

Inch Pouces Professional Hacksaw St

- Page 1608 and 1609:

Inch Pouces NEEDLE FILE SET File se

- Page 1610 and 1611:

TYPE 1 For Use with METAL, STAINLES

- Page 1612 and 1613:

Wire Wheel Brushes Use on Angle Gri

- Page 1614 and 1615:

Hammers Marteaux Ballpeen Hammer St

- Page 1616 and 1617:

Hammers Marteaux Round Face Bumping

- Page 1618 and 1619:

Body Shop Tools Outils pour atelier

- Page 1620 and 1621:

Body Shop Tools Outils pour atelier

- Page 1622 and 1623:

Body Shop Tools Outils pour atelier

- Page 1624 and 1625:

® P reverse action joint rivet for

- Page 1626 and 1627:

High Performance Plier for the Prof

- Page 1628 and 1629:

High Performance Plier for the Prof

- Page 1630 and 1631:

High Performance Plier for the Prof

- Page 1632 and 1633:

High Performance Plier for the Prof

- Page 1634 and 1635:

High Performance Plier for the Prof

- Page 1636 and 1637:

High Performance Plier for the Prof

- Page 1638 and 1639:

High Performance Plier for the Prof

- Page 1640 and 1641:

Special Selection for the Electroni

- Page 1642 and 1643:

High Performance Plier for the Prof

- Page 1644 and 1645:

High Performance Plier for the Prof

- Page 1646 and 1647:

High Performance Plier for the Prof

- Page 1648 and 1649:

ULLMAN DEVICES ® Magnet Pick-up To

- Page 1650 and 1651:

ULLMAN DEVICES ® UTILITY PACKING H

- Page 1652 and 1653:

ULLMAN DEVICES ® Inch Pouces MAGNE

- Page 1654 and 1655:

Loctite ® Products Produits Loctit

- Page 1656 and 1657:

Cyanoacrylate Adhesives Adhésifs d

- Page 1658 and 1659:

CATALOG 13 Loctite offers a complet

- Page 1660 and 1661:

Thread Sealing Scellage des filets

- Page 1662 and 1663:

Threadlocking Blocage de filets CAT

- Page 1664 and 1665:

Coatings Revêtements CATALOG 13 CO

- Page 1666 and 1667:

CATALOG 13 Spaenaur Mfg. Product No

- Page 1668 and 1669:

CATALOG 13 Spaenaur Mfg. Product No

- Page 1670 and 1671:

CATALOG 13 Spaenaur Mfg. Product No

- Page 1672 and 1673:

Flooring & Grout Couvre-sols & coul

- Page 1674 and 1675:

Gasketing and Sealing Matériaux d'

- Page 1676 and 1677:

CATALOG 13 Spaenaur Mfr. Temp. Prod

- Page 1678 and 1679:

Wearing Compounds Composés d'usure

- Page 1680 and 1681:

Cleaners Agents de nettoyage CLEANE

- Page 1682 and 1683:

CATALOG 13 PRISM Surface Insensitiv

- Page 1684 and 1685:

Comparative Charts Tableau de compa

- Page 1686 and 1687:

Metric System of Measurements Syst

- Page 1688 and 1689:

Torque Conversion Chart Tableau de

- Page 1690 and 1691:

R Thread Size Comparison Chart Tabl

- Page 1692 and 1693:

Inch Series Head Dimension Chart Di

- Page 1694 and 1695:

TAPPING SCREWS Selector Guide Guide

- Page 1696 and 1697:

R Approximate Hole Sizes in Sheet M

- Page 1698 and 1699:

Corrosion Guide Guide de corrosion

- Page 1700 and 1701:

Corrosion Guide Guide de corrosion

- Page 1702 and 1703:

Plastics Properties Chart Tableau d

- Page 1704 and 1705:

DIN/ISO Illustrated Index Index ill

- Page 1706 and 1707:

DIN/ISO Illustrated Index Index ill

- Page 1708 and 1709:

DIN/ISO Illustrated Index Index ill

- Page 1710 and 1711:

DIN/ISO Illustrated Index Index ill

- Page 1712 and 1713:

DIN/ISO Illustrated Index Index ill

- Page 1714 and 1715:

Standard Terms and Conditions of Sa

- Page 1716 and 1717:

APPLICATION FOR CREDIT FAX FORM TO

- Page 1718 and 1719:

Version 1.5 April 2, 2015 RAMPA ©

- Page 1720 and 1721:

Version 1.5 April 2, 2015 INSERTS L

- Page 1722 and 1723:

Version 1.5 April 2, 2015 RAMPA-INS

- Page 1724 and 1725:

Version 1.5 April 2, 2015 RAMPA-INS

- Page 1726 and 1727:

Version 1.5 April 2, 2015 RAMPA-INS

- Page 1728 and 1729:

Version 1.5 April 2, 2015 RAMPA-REP

- Page 1730 and 1731:

Version 1.5 April 2, 2015 RAMPA-CON

- Page 1732 and 1733:

Version 1.5 April 2, 2015 VX SELECT

- Page 1734 and 1735:

Version 1.5 April 2, 2015 RAMPA-FLA

- Page 1736 and 1737:

Version 1.5 April 2, 2015 CAP NUTS

- Page 1738 and 1739:

Version 1.5 April 2, 2015 CROSS DOW

- Page 1740 and 1741:

Version 1.5 April 2, 2015 TOOLS RAM

- Page 1742 and 1743:

Version 1.5 April 2, 2015 RAMPA-ALL

- Page 1744 and 1745:

Version 1.5 April 2, 2015 7 8 9 10

- Page 1746 and 1747:

Version 1.5 April 2, 2015 ABOUT US

- Page 1748 and 1749:

Inch Pouce U-Bolt with Nuts Low Car

- Page 1750 and 1751:

RoHS Compliant and Legacy Part Numb

- Page 1752 and 1753:

RoHS Compliant and Legacy Part Numb

- Page 1754 and 1755:

RoHS Compliant and Legacy Part Numb

- Page 1756 and 1757:

RoHS Compliant and Legacy Part Numb

- Page 1758 and 1759:

RoHS Compliant and Legacy Part Numb

- Page 1760 and 1761:

RoHS Compliant and Legacy Part Numb

- Page 1762 and 1763:

RoHS Compliant and Legacy Part Numb

- Page 1764 and 1765:

RoHS Compliant and Legacy Part Numb

- Page 1766 and 1767:

RoHS Compliant and Legacy Part Numb

- Page 1768 and 1769:

RoHS Compliant and Legacy Part Numb

- Page 1770 and 1771:

RoHS Compliant and Legacy Part Numb

- Page 1772 and 1773:

RoHS Compliant and Legacy Part Numb

- Page 1774 and 1775:

RoHS Compliant and Legacy Part Numb

- Page 1776 and 1777:

RoHS Compliant and Legacy Part Numb

- Page 1778 and 1779:

RoHS Compliant and Legacy Part Numb

- Page 1780 and 1781:

RoHS Compliant and Legacy Part Numb

- Page 1782 and 1783:

RoHS Compliant and Legacy Part Numb

- Page 1784 and 1785:

RoHS Compliant and Legacy Part Numb

- Page 1786 and 1787:

RoHS Compliant and Legacy Part Numb

- Page 1788 and 1789:

RoHS Compliant and Legacy Part Numb

- Page 1790 and 1791:

RoHS Compliant and Legacy Part Numb

- Page 1792 and 1793:

RoHS Compliant and Legacy Part Numb

- Page 1794 and 1795:

RoHS Compliant and Legacy Part Numb

- Page 1796 and 1797:

RoHS Compliant and Legacy Part Numb

- Page 1798 and 1799:

RoHS Compliant and Legacy Part Numb

- Page 1800 and 1801:

RoHS Compliant and Legacy Part Numb

- Page 1802 and 1803:

RoHS Compliant and Legacy Part Numb

- Page 1804 and 1805:

RoHS Compliant and Legacy Part Numb

- Page 1806 and 1807:

RoHS Compliant and Legacy Part Numb

- Page 1808 and 1809:

RoHS Compliant and Legacy Part Numb

- Page 1810 and 1811:

RoHS Compliant and Legacy Part Numb

- Page 1812 and 1813:

RoHS Compliant and Legacy Part Numb

- Page 1814 and 1815:

RoHS Compliant and Legacy Part Numb

- Page 1816 and 1817:

RoHS Compliant and Legacy Part Numb

- Page 1818 and 1819:

RoHS Compliant and Legacy Part Numb

- Page 1820 and 1821:

RoHS Compliant and Legacy Part Numb

- Page 1822 and 1823:

RoHS Compliant and Legacy Part Numb

- Page 1824 and 1825:

RoHS Compliant and Legacy Part Numb

- Page 1826 and 1827:

RoHS Compliant and Legacy Part Numb

- Page 1828 and 1829:

RoHS Compliant and Legacy Part Numb

- Page 1830 and 1831:

RoHS Compliant and Legacy Part Numb

- Page 1832 and 1833:

RoHS Compliant and Legacy Part Numb

- Page 1834 and 1835:

RoHS Compliant and Legacy Part Numb

- Page 1836 and 1837:

RoHS Compliant and Legacy Part Numb

- Page 1838 and 1839:

RoHS Compliant and Legacy Part Numb

- Page 1840 and 1841:

RoHS Compliant and Legacy Part Numb

- Page 1842 and 1843:

RoHS Compliant and Legacy Part Numb

- Page 1844 and 1845:

RoHS Compliant and Legacy Part Numb

- Page 1846 and 1847:

RoHS Compliant and Legacy Part Numb

- Page 1848 and 1849:

RoHS Compliant and Legacy Part Numb

- Page 1850 and 1851:

RoHS Compliant and Legacy Part Numb

- Page 1852 and 1853:

RoHS Compliant and Legacy Part Numb

- Page 1854 and 1855:

RoHS Compliant and Legacy Part Numb

- Page 1856 and 1857:

RoHS Compliant and Legacy Part Numb

- Page 1858 and 1859:

RoHS Compliant and Legacy Part Numb

- Page 1860 and 1861:

RoHS Compliant and Legacy Part Numb

- Page 1862 and 1863:

RoHS Compliant and Legacy Part Numb

- Page 1864 and 1865:

RoHS Compliant and Legacy Part Numb

- Page 1866 and 1867:

RoHS Compliant and Legacy Part Numb

- Page 1868 and 1869:

RoHS Compliant and Legacy Part Numb

- Page 1870 and 1871:

RoHS Compliant and Legacy Part Numb

- Page 1872 and 1873:

RoHS Compliant and Legacy Part Numb

- Page 1874 and 1875:

RoHS Compliant and Legacy Part Numb

- Page 1876 and 1877:

RoHS Compliant and Legacy Part Numb

- Page 1878 and 1879:

RoHS Compliant and Legacy Part Numb

- Page 1880 and 1881:

RoHS Compliant and Legacy Part Numb

- Page 1882 and 1883:

RoHS Compliant and Legacy Part Numb

- Page 1884 and 1885:

RoHS Compliant and Legacy Part Numb

- Page 1886 and 1887:

RoHS Compliant and Legacy Part Numb

- Page 1888 and 1889:

RoHS Compliant and Legacy Part Numb

- Page 1890 and 1891:

RoHS Compliant and Legacy Part Numb

- Page 1892 and 1893:

RoHS Compliant and Legacy Part Numb

- Page 1894 and 1895:

RoHS Compliant and Legacy Part Numb

- Page 1896 and 1897:

RoHS Compliant and Legacy Part Numb

- Page 1898 and 1899:

RoHS Compliant and Legacy Part Numb

- Page 1900 and 1901:

RoHS Compliant and Legacy Part Numb

- Page 1902 and 1903:

RoHS Compliant and Legacy Part Numb

- Page 1904 and 1905:

RoHS Compliant and Legacy Part Numb

- Page 1906 and 1907:

RoHS Compliant and Legacy Part Numb

- Page 1908 and 1909:

RoHS Compliant and Legacy Part Numb

- Page 1910 and 1911:

RoHS Compliant and Legacy Part Numb

- Page 1912 and 1913:

RoHS Compliant and Legacy Part Numb

- Page 1914 and 1915:

RoHS Compliant and Legacy Part Numb

- Page 1916 and 1917:

RoHS Compliant and Legacy Part Numb

- Page 1918 and 1919:

RoHS Compliant and Legacy Part Numb

- Page 1920 and 1921:

RoHS Compliant and Legacy Part Numb

- Page 1922 and 1923:

RoHS Compliant and Legacy Part Numb

- Page 1924 and 1925:

RoHS Compliant and Legacy Part Numb

- Page 1926 and 1927:

RoHS Compliant and Legacy Part Numb

- Page 1928 and 1929:

RoHS Compliant and Legacy Part Numb

- Page 1930 and 1931:

RoHS Compliant and Legacy Part Numb

- Page 1932 and 1933:

RoHS Compliant and Legacy Part Numb

- Page 1934 and 1935:

RoHS Compliant and Legacy Part Numb

- Page 1936 and 1937:

RoHS Compliant and Legacy Part Numb

- Page 1938 and 1939:

RoHS Compliant and Legacy Part Numb

- Page 1940 and 1941:

RoHS Compliant and Legacy Part Numb

- Page 1942 and 1943:

RoHS Compliant and Legacy Part Numb

- Page 1944 and 1945:

RoHS Compliant and Legacy Part Numb

- Page 1946 and 1947:

RoHS Compliant and Legacy Part Numb

- Page 1948 and 1949:

RoHS Compliant and Legacy Part Numb

- Page 1950 and 1951:

RoHS Compliant and Legacy Part Numb

- Page 1952 and 1953:

RoHS Compliant and Legacy Part Numb

- Page 1954 and 1955:

RoHS Compliant and Legacy Part Numb

- Page 1956 and 1957:

RoHS Compliant and Legacy Part Numb

- Page 1958 and 1959:

RoHS Compliant and Legacy Part Numb

- Page 1960 and 1961:

RoHS Compliant and Legacy Part Numb

- Page 1962 and 1963:

RoHS Compliant and Legacy Part Numb

- Page 1964 and 1965:

RoHS Compliant and Legacy Part Numb

- Page 1966 and 1967:

RoHS Compliant and Legacy Part Numb

- Page 1968 and 1969:

RoHS Compliant and Legacy Part Numb

- Page 1970 and 1971:

RoHS Compliant and Legacy Part Numb

- Page 1972 and 1973:

RoHS Compliant and Legacy Part Numb

- Page 1974 and 1975:

RoHS Compliant and Legacy Part Numb

- Page 1976 and 1977:

RoHS Compliant and Legacy Part Numb

- Page 1978 and 1979:

RoHS Compliant and Legacy Part Numb

- Page 1980 and 1981:

RoHS Compliant and Legacy Part Numb

- Page 1982 and 1983:

RoHS Compliant and Legacy Part Numb

- Page 1984 and 1985:

RoHS Compliant and Legacy Part Numb

- Page 1986 and 1987:

RoHS Compliant and Legacy Part Numb

- Page 1988 and 1989:

RoHS Compliant and Legacy Part Numb

- Page 1990 and 1991:

RoHS Compliant and Legacy Part Numb

- Page 1992 and 1993:

RoHS Compliant and Legacy Part Numb

- Page 1994 and 1995:

RoHS Compliant and Legacy Part Numb

- Page 1996 and 1997:

RoHS Compliant and Legacy Part Numb

- Page 1998 and 1999:

RoHS Compliant and Legacy Part Numb

- Page 2000 and 2001:

RoHS Compliant and Legacy Part Numb

- Page 2002 and 2003:

RoHS Compliant and Legacy Part Numb

- Page 2004 and 2005:

RoHS Compliant and Legacy Part Numb

- Page 2006 and 2007:

RoHS Compliant and Legacy Part Numb

- Page 2008 and 2009:

RoHS Compliant and Legacy Part Numb

- Page 2010 and 2011:

RoHS Compliant and Legacy Part Numb

- Page 2012 and 2013:

RoHS Compliant and Legacy Part Numb

- Page 2014 and 2015:

RoHS Compliant and Legacy Part Numb

- Page 2016 and 2017:

RoHS Compliant and Legacy Part Numb

- Page 2018 and 2019:

RoHS Compliant and Legacy Part Numb

- Page 2020 and 2021:

Inch Pouce cedar deck screws - squa

- Page 2022 and 2023:

SAVE big over LOCTITE ® , with VIB

- Page 2024:

~~ SPAENAUR Head Office & Main Dist