Climate Action 2009-2010

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

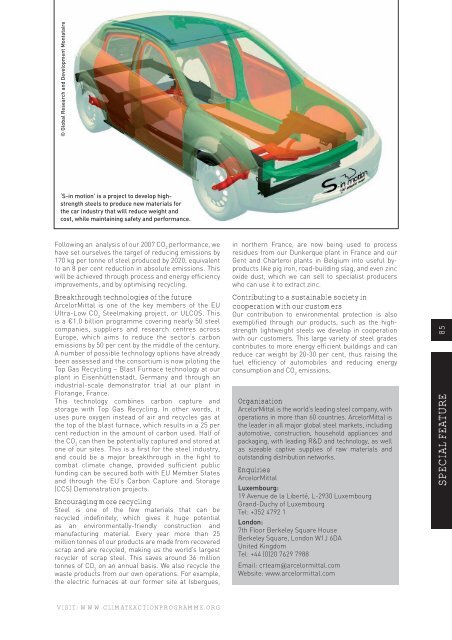

© Global Research and Development Montataire<br />

‘S-in motion’ is a project to develop highstrength<br />

steels to produce new materials for<br />

the car industry that will reduce weight and<br />

cost, while maintaining safety and performance.<br />

Following an analysis of our 2007 CO 2<br />

performance, we<br />

have set ourselves the target of reducing emissions by<br />

170 kg per tonne of steel produced by 2020, equivalent<br />

to an 8 per cent reduction in absolute emissions. This<br />

will be achieved through process and energy efficiency<br />

improvements, and by optimising recycling.<br />

Breakthrough technologies of the future<br />

ArcelorMittal is one of the key members of the EU<br />

Ultra-Low CO 2<br />

Steelmaking project, or ULCOS. This<br />

is a €1.0 billion programme covering nearly 50 steel<br />

companies, suppliers and research centres across<br />

Europe, which aims to reduce the sector’s carbon<br />

emissions by 50 per cent by the middle of the century.<br />

A number of possible technology options have already<br />

been assessed and the consortium is now piloting the<br />

Top Gas Recycling – Blast Furnace technology at our<br />

plant in Eisenhüttenstadt, Germany and through an<br />

industrial-scale demonstrator trial at our plant in<br />

Florange, France.<br />

This technology combines carbon capture and<br />

storage with Top Gas Recycling. In other words, it<br />

uses pure oxygen instead of air and recycles gas at<br />

the top of the blast furnace, which results in a 25 per<br />

cent reduction in the amount of carbon used. Half of<br />

the CO 2<br />

can then be potentially captured and stored at<br />

one of our sites. This is a first for the steel industry,<br />

and could be a major breakthrough in the fight to<br />

combat climate change, provided sufficient public<br />

funding can be secured both with EU Member States<br />

and through the EU’s Carbon Capture and Storage<br />

(CCS) Demonstration projects.<br />

Encouraging more recycling<br />

Steel is one of the few materials that can be<br />

recycled indefinitely, which gives it huge potential<br />

as an environmentally-friendly construction and<br />

manufacturing material. Every year more than 25<br />

million tonnes of our products are made from recovered<br />

scrap and are recycled, making us the world’s largest<br />

recycler of scrap steel. This saves around 36 million<br />

tonnes of CO 2<br />

on an annual basis. We also recycle the<br />

waste products from our own operations. For example,<br />

the electric furnaces at our former site at Isbergues,<br />

in northern France, are now being used to process<br />

residues from our Dunkerque plant in France and our<br />

Gent and Charleroi plants in Belgium into useful byproducts<br />

like pig iron, road-building slag, and even zinc<br />

oxide dust, which we can sell to specialist producers<br />

who can use it to extract zinc.<br />

Contributing to a sustainable society in<br />

cooperation with our customers<br />

Our contribution to environmental protection is also<br />

exemplified through our products, such as the highstrength<br />

lightweight steels we develop in cooperation<br />

with our customers. This large variety of steel grades<br />

contributes to more energy efficient buildings and can<br />

reduce car weight by 20-30 per cent, thus raising the<br />

fuel efficiency of automobiles and reducing energy<br />

consumption and CO 2<br />

emissions.<br />

Organisation<br />

ArcelorMittal is the world’s leading steel company, with<br />

operations in more than 60 countries. ArcelorMittal is<br />

the leader in all major global steel markets, including<br />

automotive, construction, household appliances and<br />

packaging, with leading R&D and technology, as well<br />

as sizeable captive supplies of raw materials and<br />

outstanding distribution networks.<br />

Enquiries<br />

ArcelorMittal<br />

Luxembourg:<br />

19 Avenue de la Liberté, L-2930 Luxembourg<br />

Grand-Duchy of Luxembourg<br />

Tel: +352 4792 1<br />

London:<br />

7th Floor Berkeley Square House<br />

Berkeley Square, London W1J 6DA<br />

United Kingdom<br />

Tel: +44 (0)20 7629 7988<br />

Email: crteam@arcelormittal.com<br />

Website: www.arcelormittal.com<br />

SPECIAL FEATURE 85<br />

VISIT: WWW.CLIMATEACTIONPROGRAMME.ORG