STEEL + TECHNOLOGY 01/2019

- STEEL COMPANIES: Implementation of the new continuous casting plant at Saarstahl is on track - STEEL TECHNOLOGY: Ultra-thin hot rolled strip with only 0.6 mm thickness produced on Arvedi ESP line - ADDITIVE MANUFACTURING. 3D spray head for forging presses wins German Design Award

- STEEL COMPANIES: Implementation of the new continuous casting plant at Saarstahl

is on track

- STEEL TECHNOLOGY: Ultra-thin hot rolled strip with only 0.6 mm thickness produced on Arvedi ESP line

- ADDITIVE MANUFACTURING. 3D spray head for forging presses wins German Design Award

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

48 | <strong>STEEL</strong> <strong>TECHNOLOGY</strong><br />

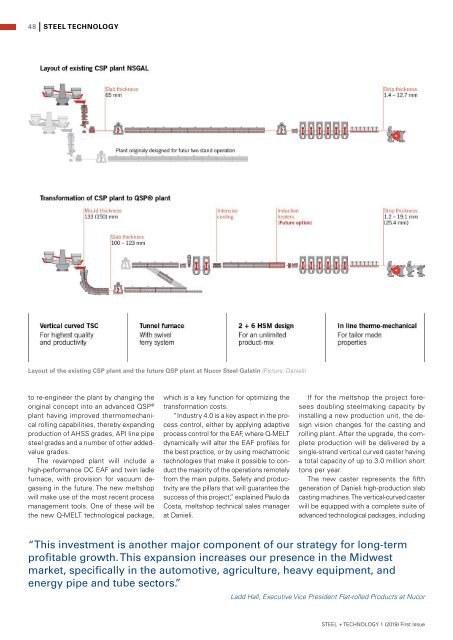

Layout of the existing CSP plant and the future QSP plant at Nucor Steel Galatin (Picture: Danieli)<br />

to re-engineer the plant by changing the<br />

original concept into an advanced QSP ®<br />

plant having improved thermomechanical<br />

rolling capabilities, thereby expanding<br />

production of AHSS grades, API line pipe<br />

steel grades and a number of other addedvalue<br />

grades.<br />

The revamped plant will include a<br />

high-performance DC EAF and twin ladle<br />

furnace, with provision for vacuum degassing<br />

in the future. The new meltshop<br />

will make use of the most recent process<br />

management tools. One of these will be<br />

the new Q-MELT technological package,<br />

which is a key function for optimizing the<br />

transformation costs.<br />

“Industry 4.0 is a key aspect in the process<br />

control, either by applying adaptive<br />

process control for the EAF, where Q-MELT<br />

dynamically will alter the EAF profiles for<br />

the best practice, or by using mechatronic<br />

technologies that make it possible to conduct<br />

the majority of the operations remotely<br />

from the main pulpits. Safety and productivity<br />

are the pillars that will guarantee the<br />

success of this project,” explained Paulo da<br />

Costa, meltshop technical sales manager<br />

at Danieli.<br />

If for the meltshop the project foresees<br />

doubling steelmaking capacity by<br />

installing a new production unit, the design<br />

vision changes for the casting and<br />

rolling plant. After the upgrade, the complete<br />

production will be delivered by a<br />

single-strand vertical curved caster having<br />

a total capacity of up to 3.0 million short<br />

tons per year.<br />

The new caster represents the fifth<br />

generation of Danieli high-production slab<br />

casting machines. The vertical-curved caster<br />

will be equipped with a complete suite of<br />

advanced technological packages, including<br />

“This investment is another major component of our strategy for long-term<br />

profitable growth. This expansion increases our presence in the Midwest<br />

market, specifically in the automotive, agriculture, heavy equipment, and<br />

energy pipe and tube sectors.”<br />

Ladd Hall, Executive Vice President Flat-rolled Products at Nucor<br />

<strong>STEEL</strong> + <strong>TECHNOLOGY</strong> 1 (2<strong>01</strong>9) First Issue