CPT International 4/2019

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PRESSURE DIE CASTING<br />

Photo: ??<br />

Light-weight castings can be<br />

joined by means of latest laser<br />

welding methods to manufacture<br />

highly loadable and economically<br />

efficient structural components.<br />

Castings for lightweight<br />

engineering<br />

Cast iron and aluminium alloys as alternatives for<br />

thin-section steel castings.<br />

Wolfgang Knothe, Franken Guss, Kitzingen<br />

The urgent call for light-weighting<br />

solutions in automotive engineering<br />

entails two key requirements:<br />

reliable and consistent material properties<br />

of the component, and a design suitable<br />

for the expected in-service stress<br />

load of the component. In other words,<br />

the service life of a component depends<br />

to a large extent on the component<br />

design. This is where casting technology<br />

comes in because here both the geometry<br />

of a component and the material<br />

properties evolve in one and the same<br />

process. Additionally, thanks to the high<br />

degree of process automation, large<br />

series production is assured.<br />

Steel casting has its limits, above all<br />

for economic reasons. Steel‘s very high<br />

melting and casting temperatures, its<br />

high shrinkage rates and the complexity<br />

of steel heat treatments are the main<br />

causes for this. The development of<br />

advanced materials, such as ductile iron<br />

and T6 aluminium alloys, has overcome<br />

these constraints. This does not mean<br />

that the importance of aluminium as<br />

the classical light-weighting material<br />

has decreased. While ductile iron and<br />

steel alloys have similar properties, the<br />

melting temperature of ductile iron is<br />

lower by 400 K, giving it excellent teeming<br />

properties. Meanwhile, a number<br />

of highly loaded structural parts which<br />

used to be exclusively made of steel<br />

have been replaced by ductile iron castings.<br />

Ductile iron castings are characterized<br />

by the following features:<br />

a b c<br />

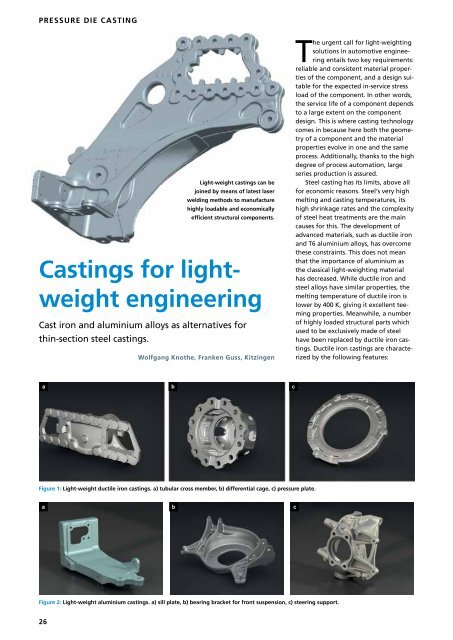

Figure 1: Light-weight ductile iron castings. a) tubular cross member, b) differential cage, c) pressure plate.<br />

a b c<br />

Figure 2: Light-weight aluminium castings. a) sill plate, b) bearing bracket for front suspension, c) steering support.<br />

26