CPT International 4/2019

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

a<br />

Nuremberg, Germany<br />

14 –16.1.2020<br />

b<br />

<strong>International</strong> Trade Fair for Die Casting:<br />

Technology, Processes, Products<br />

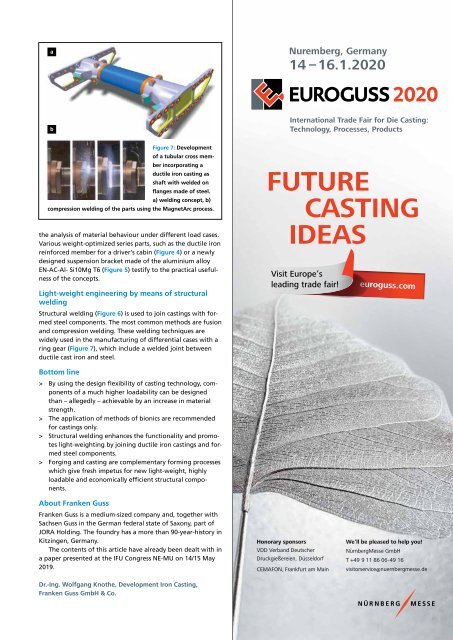

Figure 7: Development<br />

of a tubular cross member<br />

incorporating a<br />

ductile iron casting as<br />

shaft with welded on<br />

flanges made of steel.<br />

a) welding concept, b)<br />

compression welding of the parts using the MagnetArc process.<br />

the analysis of material behaviour under different load cases.<br />

Various weight-optimized series parts, such as the ductile iron<br />

reinforced member for a driver‘s cabin (Figure 4) or a newly<br />

designed suspension bracket made of the aluminium alloy<br />

EN-AC-Al- Si10Mg T6 (Figure 5) testify to the practical usefulness<br />

of the concepts.<br />

Light-weight engineering by means of structural<br />

welding<br />

Structural welding (Figure 6) is used to join castings with formed<br />

steel components. The most common methods are fusion<br />

and compression welding. These welding techniques are<br />

widely used in the manufacturing of differential cases with a<br />

ring gear (Figure 7), which include a welded joint between<br />

ductile cast iron and steel.<br />

FUTURE<br />

CASTING<br />

IDEAS<br />

Visit Europe’s<br />

leading trade fair!<br />

euroguss.com<br />

Bottom line<br />

> By using the design flexibility of casting technology, components<br />

of a much higher loadability can be designed<br />

than – allegedly – achievable by an increase in material<br />

strength.<br />

> The application of methods of bionics are recommended<br />

for castings only.<br />

> Structural welding enhances the functionality and promotes<br />

light-weighting by joining ductile iron castings and formed<br />

steel components.<br />

> Forging and casting are complementary forming processes<br />

which give fresh impetus for new light-weight, highly<br />

loadable and economically efficient structural components.<br />

About Franken Guss<br />

Franken Guss is a medium-sized company and, together with<br />

Sachsen Guss in the German federal state of Saxony, part of<br />

JORA Holding. The foundry has a more than 90-year-history in<br />

Kitzingen, Germany.<br />

The contents of this article have already been dealt with in<br />

a paper presented at the IFU Congress NE-MU on 14/15 May<br />

<strong>2019</strong>.<br />

Dr.-Ing. Wolfgang Knothe, Development Iron Casting,<br />

Franken Guss GmbH & Co.<br />

Honorary sponsors<br />

VDD Verband Deutscher<br />

Druckgießereien, Düsseldorf<br />

CEMAFON, Frankfurt am Main<br />

We’ll be pleased to help you!<br />

NürnbergMesse GmbH<br />

T +49 9 11 86 06-49 16<br />

visitorservice@nuernbergmesse.de<br />

CASTING PLANT & TECHNOLOGY 4/<strong>2019</strong> 29