CPT International 4/2019

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PRESSURE DIE CASTING<br />

a<br />

c<br />

b<br />

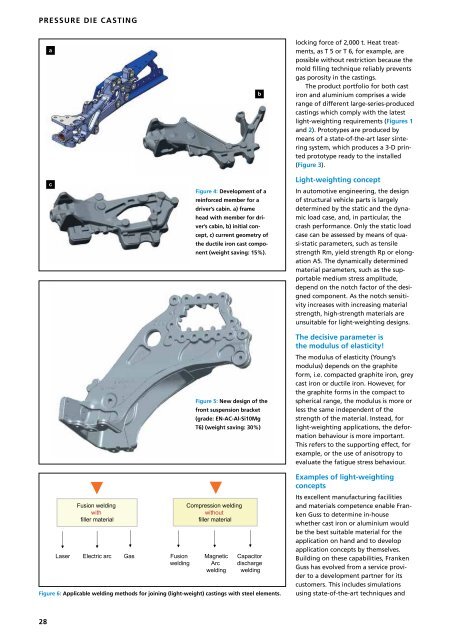

Figure 4: Development of a<br />

reinforced member for a<br />

driver’s cabin. a) frame<br />

head with member for driver’s<br />

cabin, b) initial concept,<br />

c) current geometry of<br />

the ductile iron cast component<br />

(weight saving: 15%).<br />

Figure 5: New design of the<br />

front suspension bracket<br />

(grade: EN-AC-Al-Si10Mg<br />

T6) (weight saving: 30%)<br />

locking force of 2,000 t. Heat treatments,<br />

as T 5 or T 6, for example, are<br />

possible without restriction because the<br />

mold filling technique reliably prevents<br />

gas porosity in the castings.<br />

The product portfolio for both cast<br />

iron and aluminium comprises a wide<br />

range of different large-series-produced<br />

castings which comply with the latest<br />

light-weighting requirements (Figures 1<br />

and 2). Prototypes are produced by<br />

means of a state-of-the-art laser sintering<br />

system, which produces a 3-D printed<br />

prototype ready to the installed<br />

(Figure 3).<br />

Light-weighting concept<br />

In automotive engineering, the design<br />

of structural vehicle parts is largely<br />

determined by the static and the dynamic<br />

load case, and, in particular, the<br />

crash performance. Only the static load<br />

case can be assessed by means of quasi-static<br />

parameters, such as tensile<br />

strength Rm, yield strength Rp or elongation<br />

A5. The dynamically determined<br />

material parameters, such as the supportable<br />

medium stress amplitude,<br />

depend on the notch factor of the designed<br />

component. As the notch sensitivity<br />

increases with increasing material<br />

strength, high-strength materials are<br />

unsuitable for light-weighting designs.<br />

The decisive parameter is<br />

the modulus of elasticity!<br />

The modulus of elasticity (Young’s<br />

modulus) depends on the graphite<br />

form, i.e. compacted graphite iron, grey<br />

cast iron or ductile iron. However, for<br />

the graphite forms in the compact to<br />

spherical range, the modulus is more or<br />

less the same independent of the<br />

strength of the material. Instead, for<br />

light-weighting applications, the deformation<br />

behaviour is more important.<br />

This refers to the supporting effect, for<br />

example, or the use of anisotropy to<br />

evaluate the fatigue stress behaviour.<br />

Fusion welding<br />

with<br />

filler material<br />

Laser Electric arc Gas Fusion<br />

welding<br />

Compression welding<br />

without<br />

filler material<br />

Magnetic<br />

Arc<br />

welding<br />

Capacitor<br />

discharge<br />

welding<br />

Figure 6: Applicable welding methods for joining (light-weight) castings with steel elements.<br />

Examples of light-weighting<br />

concepts<br />

Its excellent manufacturing facilities<br />

and materials competence enable Franken<br />

Guss to determine in-house<br />

whether cast iron or aluminium would<br />

be the best suitable material for the<br />

application on hand and to develop<br />

application concepts by themselves.<br />

Building on these capabilities, Franken<br />

Guss has evolved from a service provider<br />

to a development partner for its<br />

customers. This includes simulations<br />

using state-of-the-art techniques and<br />

28