Jewellery World Magazine - May 2021

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

KEEPING SKILLS ALIVE<br />

How To Make A Shank Punch<br />

Jewellers will often have to make specialised tools for certain<br />

tasks. For sizing stone set rings up, you can solder a piece into the<br />

shank or if it’s only one or two sizes and the shank isn’t too worn,<br />

you can stretch it to size.<br />

In this tutorial you will learn how to make a specially shaped<br />

punch for sizing rings.<br />

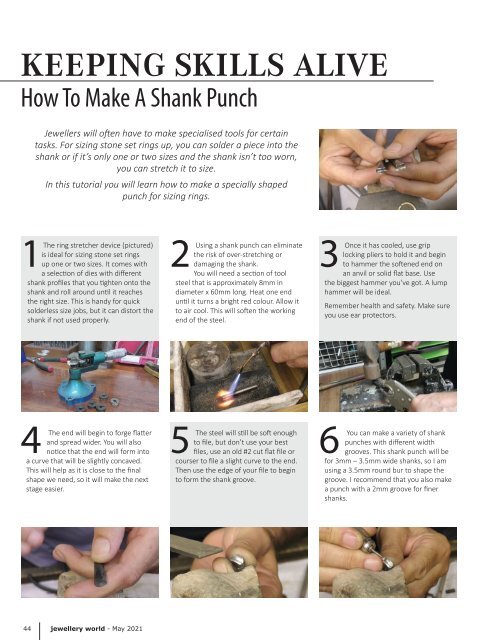

1The ring stretcher device (pictured)<br />

is ideal for sizing stone set rings<br />

up one or two sizes. It comes with<br />

a selection of dies with different<br />

shank profiles that you tighten onto the<br />

shank and roll around until it reaches<br />

the right size. This is handy for quick<br />

solderless size jobs, but it can distort the<br />

shank if not used properly.<br />

2<br />

Using a shank punch can eliminate<br />

the risk of over-stretching or<br />

damaging the shank.<br />

You will need a section of tool<br />

steel that is approximately 8mm in<br />

diameter x 60mm long. Heat one end<br />

until it turns a bright red colour. Allow it<br />

to air cool. This will soften the working<br />

end of the steel.<br />

3<br />

Once it has cooled, use grip<br />

locking pliers to hold it and begin<br />

to hammer the softened end on<br />

an anvil or solid flat base. Use<br />

the biggest hammer you’ve got. A lump<br />

hammer will be ideal.<br />

Remember health and safety. Make sure<br />

you use ear protectors.<br />

4<br />

The end will begin to forge flatter<br />

and spread wider. You will also<br />

notice that the end will form into<br />

a curve that will be slightly concaved.<br />

This will help as it is close to the final<br />

shape we need, so it will make the next<br />

stage easier.<br />

5<br />

The steel will still be soft enough<br />

to file, but don’t use your best<br />

files, use an old #2 cut flat file or<br />

courser to file a slight curve to the end.<br />

Then use the edge of your file to begin<br />

to form the shank groove.<br />

6<br />

You can make a variety of shank<br />

punches with different width<br />

grooves. This shank punch will be<br />

for 3mm – 3.5mm wide shanks, so I am<br />

using a 3.5mm round bur to shape the<br />

groove. I recommend that you also make<br />

a punch with a 2mm groove for finer<br />

shanks.<br />

44<br />

jewellery world - <strong>May</strong> <strong>2021</strong>