Jewellery World Magazine - May 2021

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

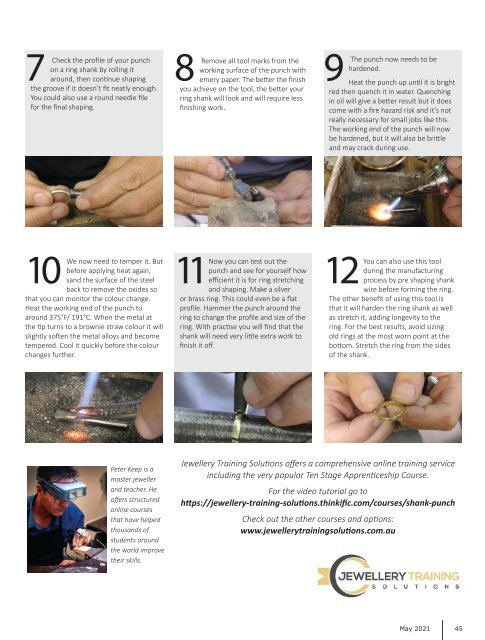

7<br />

Check the profile of your punch<br />

on a ring shank by rolling it<br />

around, then continue shaping<br />

the groove if it doesn’t fit neatly enough.<br />

You could also use a round needle file<br />

for the final shaping.<br />

8<br />

Remove all tool marks from the<br />

working surface of the punch with<br />

emery paper. The better the finish<br />

you achieve on the tool, the better your<br />

ring shank will look and will require less<br />

finishing work.<br />

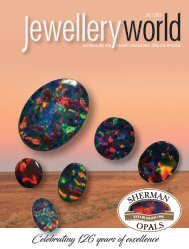

9<br />

The punch now needs to be<br />

hardened.<br />

Heat the punch up until it is bright<br />

red then quench it in water. Quenching<br />

in oil will give a better result but it does<br />

come with a fire hazard risk and it’s not<br />

really necessary for small jobs like this.<br />

The working end of the punch will now<br />

be hardened, but it will also be brittle<br />

and may crack during use.<br />

10<br />

We now need to temper it. But<br />

before applying heat again,<br />

sand the surface of the steel<br />

back to remove the oxides so<br />

that you can monitor the colour change.<br />

Heat the working end of the punch to<br />

around 375°F/ 191°C. When the metal at<br />

the tip turns to a brownie straw colour it will<br />

slightly soften the metal alloys and become<br />

tempered. Cool it quickly before the colour<br />

changes further.<br />

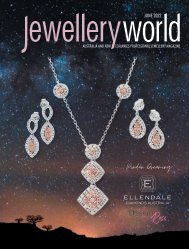

11efficient it is for ring stretching<br />

Now you can test out the<br />

punch and see for yourself how<br />

and shaping. Make a silver<br />

or brass ring. This could even be a flat<br />

profile. Hammer the punch around the<br />

ring to change the profile and size of the<br />

ring. With practise you will find that the<br />

shank will need very little extra work to<br />

finish it off.<br />

12<br />

You can also use this tool<br />

during the manufacturing<br />

process by pre shaping shank<br />

wire before forming the ring.<br />

The other benefit of using this tool is<br />

that it will harden the ring shank as well<br />

as stretch it, adding longevity to the<br />

ring. For the best results, avoid sizing<br />

old rings at the most worn point at the<br />

bottom. Stretch the ring from the sides<br />

of the shank.<br />

Peter Keep is a<br />

master jeweller<br />

and teacher. He<br />

offers structured<br />

online courses<br />

that have helped<br />

thousands of<br />

students around<br />

the world improve<br />

their skills.<br />

<strong>Jewellery</strong> Training Solutions offers a comprehensive online training service<br />

including the very popular Ten Stage Apprenticeship Course.<br />

For the video tutorial go to<br />

https://jewellery-training-solutions.thinkific.com/courses/shank-punch<br />

Check out the other courses and options:<br />

www.jewellerytrainingsolutions.com.au<br />

<strong>May</strong> <strong>2021</strong> 45