- Page 1 and 2: This document was too large to scan

- Page 3 and 4: DMJM H&N AECQM RPP-24544 REV Id Pag

- Page 5 and 6: 0 DMJM H&N I AECOM Calculation No 1

- Page 7 and 8: DMJM H&N AECOM I Calculation No 145

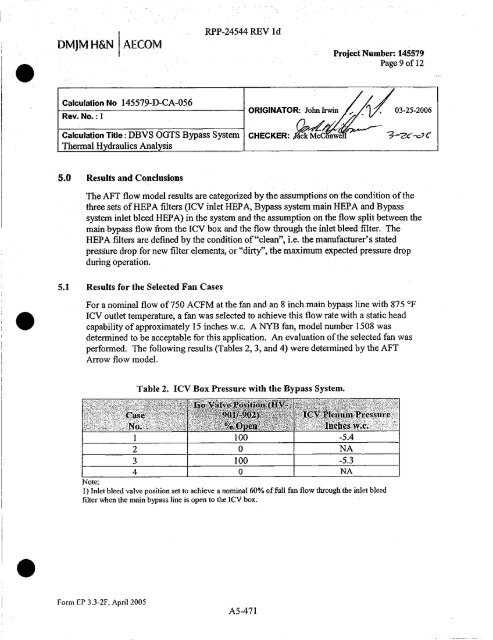

- Page 9: • DMJM H&N I AECOM Calculation No

- Page 13 and 14: I• • r1 LJ DM]M H&N AECOM I Cal

- Page 15 and 16: • • i DMJM H&N ( AECOM Calculat

- Page 17 and 18: • RPP-24544 REV id Calculation No

- Page 19 and 20: • LJ C', B A Ii wm" BOY NOTES, ©

- Page 21 and 22: • 0 0 . 78. 5. 4 3 RPP-24544 REV

- Page 23 and 24: • u ^I / s FI _- / I =I I 1 / 1 1

- Page 25 and 26: i RPP-24544 REV 1d Calculation No.

- Page 27 and 28: • • F E BI 6 A 8 7 6 a 8 SECTIO

- Page 29 and 30: 0 Q C e A 1 i e 13 7 6 5 4 3 2 1 wo

- Page 31 and 32: V m ` 1 1 y j9ppL{ bi N gp N ^ R\

- Page 33 and 34: • • • RPP-24544 REV Id Calcul

- Page 35 and 36: E 0 RPP-24544 REV 1d Calculation No

- Page 37 and 38: u E RPP-24544 RFV" a Calculation No

- Page 39 and 40: L 1 RPP-24544 REV Id Calculation No

- Page 41 and 42: • • • RPP-24544 REV ld Calcul

- Page 43 and 44: • E • RPP-24544 REV ld Calculat

- Page 45 and 46: • • RPP-24544 REV Id Calculatio

- Page 47 and 48: • • • RPP-24544 REV Id Calcul

- Page 49 and 50: • RPP-24544 REV Id Calculation No

- Page 51 and 52: 7 • • RPP-24544 REV let Calcula

- Page 53 and 54: • AFTAO 0 RPP-24544 REV Id Calcul

- Page 55 and 56: • • . RPP-24544 REV 18 alculati

- Page 57 and 58: 0 RPP-24544 REV Id Calculation No.

- Page 59 and 60: • RPP-24544 REV Id Calculation No

- Page 61 and 62:

• • RPP-24544 REV Id Calculatio

- Page 63 and 64:

• • RPP-24544 RFV Id Calculatio

- Page 65 and 66:

III • • E RPP-24544 REV id Calc

- Page 67 and 68:

0 • • RPP-24544 REV Id Calculat

- Page 69 and 70:

• I* RPP-24544 REV Id Calculation

- Page 71 and 72:

I • • • RPP-24544 REV Id Calc

- Page 73 and 74:

• • AFTAnmvw ooulglt (ids) 2!25

- Page 75 and 76:

• • AFT Anow 3.0 OUtpW - (3 01

- Page 77 and 78:

0 • • AFfA 3.00utput (So/5) 312

- Page 79 and 80:

• is This page intentionally left

- Page 81 and 82:

a A . • Calculation No. 145579-D-

- Page 83 and 84:

0 Y, inaw . • Calculation No. 145

- Page 85 and 86:

a Y, in A Calculation No. 145579-DA

- Page 87 and 88:

• • Calculation No. 145579-D-06

- Page 89 and 90:

v, A • • Calculation No. 145579

- Page 91 and 92:

• . Calculation No. 145579-D-606,

- Page 93 and 94:

a in w Calculation No. 145579-DA6,

- Page 95 and 96:

0 • RPP-24544 REV ld Calculation

- Page 97 and 98:

ON • • Calculation No. 145579-D

- Page 99 and 100:

h OGTS Bypass External Convection a

- Page 101 and 102:

• • RPP-24544'REV id This page

- Page 103 and 104:

f- - ANSI 816.1041976 Maximum Leaka

- Page 105 and 106:

Y, in rn Pressure Blower 1503 Steel

- Page 107 and 108:

RPP-24544 REV ld Calculation No. 14

- Page 109 and 110:

• • RPP`-24544 REV Id Calculati

- Page 111 and 112:

• • RPP-24544'REV id Calculatio

- Page 113 and 114:

1 1 ___ t-^q f ^ 1 v^ci-.- 1u o -^-

- Page 115 and 116:

. • RPP-24544 REV ld AJAR A4/A, 0

- Page 117 and 118:

I Eq. 9 •, 1 11 lwl 1111 'LL, , ,

- Page 119 and 120:

• • EA5-2^V}r, 45 Degree, Cotwe

- Page 121 and 122:

. • RPP-24544 REV Id CalculationN

- Page 123 and 124:

Dud Desiga EUS-31Yc,:Dr rlOin.. Com

- Page 125 and 126:

• • E DuctDesign EM-3 Tee,Dr >

- Page 127 and 128:

a Y, 00 -11 ^rnll P P 8 pp POP= L L

- Page 129 and 130:

. • 35.43 SD4.7. Tmsl tlon, Round

- Page 131 and 132:

Daet Design RPP-24544'REV 1'd CR3.9

- Page 133 and 134:

• I RPP-24544 REV Id Calculation

- Page 135 and 136:

• • • ERM Maw. 90 Degree, Var

- Page 137 and 138:

0 • Duct Design SR3-1 Elbow, 991)

- Page 139 and 140:

• • • RPP-24544 REV Id Calcul

- Page 141 and 142:

2. Spreadsheet Owner, Organization,

- Page 143 and 144:

DMJM H&N A3Ivi Calculation No 14557

- Page 145 and 146:

W RPP-24544 REV I Calculation No. 1

- Page 147 and 148:

.*I— RPP-24544 REV I d Calculatio

- Page 149 and 150:

3 lh all 0 ^t OGTS Bypass System Fl

- Page 151 and 152:

a OGTS Bypass System Fluid Flow Mod

- Page 153 and 154:

io. tj chi, I OGTS Bypass System Fl

- Page 155 and 156:

v, OGTS Bypass System Fluid Flow Mo

- Page 157 and 158:

v^ OGTS Bypass System Fluid Flow Mo

- Page 159 and 160:

a Y, OGTS Bypass System Fluid Flow

- Page 161 and 162:

• I Q • D A a RPP-24544 REV I C

- Page 163 and 164:

• 11 r1 LJ Tel: RPP-24544 REV id

- Page 165 and 166:

37th.. of C^ t 01G I'S Bypass Syste

- Page 167 and 168:

1) "I HEPA Fnhcr, 36-NO2-131 Flande

- Page 169 and 170:

i Y" c^ N j of OGTS Bypass External

- Page 171 and 172:

Y, w i Radiation component: I OGTS

- Page 173 and 174:

££9-Sd PI AgS tt5K-d" _ N, i— ^

- Page 175 and 176:

• • L J RPP-24544 REV Id This p

- Page 177 and 178:

• • CALCULATION SHEET M RPP-245

- Page 179 and 180:

CALCULATION SHEET CAM Nos 145579-V-

- Page 181 and 182:

• Calculation No. 145579-V-CA-004

- Page 184 and 185:

• is Calculation No. 145579-V-CA-

- Page 186 and 187:

0 \J • RPP-24544 REV Id - ^(q Pro

- Page 189:

7 0 RPP-24544 REV I 145579-V-CA-004

- Page 192 and 193:

• 11 0 ^ 3j o N^ '/ M.^^^9 RPP-24

- Page 194 and 195:

• i r RPP-24544 REV 1 d 145579-V-

- Page 196 and 197:

0 RPP-24544 REV I 145579-V-CA-004 A

- Page 198 and 199:

RPP-24544 REV 1 d 0 Nonresidgnt(al

- Page 200 and 201:

C g 41 N O 2 RPP-24544 REV Id 33.4

- Page 202 and 203:

11 0 RPP-24544 REV I 145579 -V-CA-0

- Page 204 and 205:

W • • 3. From the Ratings on pa

- Page 206 and 207:

E • Wafer Pressure Drop n 100.0 0

- Page 208:

0 RPP-24544 REV I 145579-V-CA-004 A

- Page 211 and 212:

0 0 Ln CAST BONNET Provides flu id

- Page 213 and 214:

STEP 4: Calculate the area required

- Page 215 and 216:

0 u • . . - I .E COMMON DIMENSION

- Page 217 and 218:

RPP-24544 REV )d CS & STC Series in

- Page 219 and 220:

• is RPP-24544 REV I d • Figure