0 - Hanford Site

0 - Hanford Site

0 - Hanford Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

RPP-24544 REV )d<br />

CS & STC Series installation & maintenance<br />

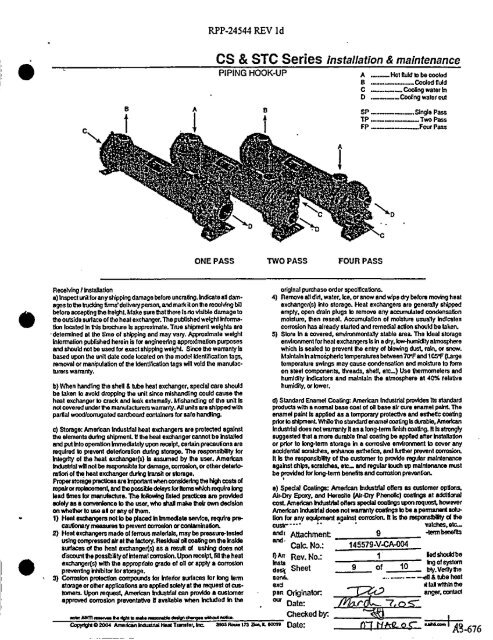

• PIPING HOOK-UP A ._..-_.Hot fluid to be cooled<br />

8 .__----Coded fl<br />

uid<br />

C .__.___._.. Cooling water In<br />

D ___-Coo lingwatorcut<br />

CJ<br />

0<br />

Receiving I hista llation<br />

a) Inspect unit forany shipping damage befo re uncrating.ln?icate ati dam.<br />

egos to the buc king fums'dot iveryperson, and mark iton the recoiving bV<br />

before accep ti ng the height. Make sure that there Is no vi sible damage to<br />

the outside s ur face of the heat exchanger. The published weight Infortmtlon<br />

located In t hi<br />

s b roch ur e Is approximate. True shipment weights are<br />

determined at the time of shipping and may va ry. Approximate weight<br />

Inforrnati on published herein is for engineering app ro ximation purposes<br />

and should rot be used for exact s hi<br />

pping weight. Vince the warran ty is<br />

based upon the unit date code located on the model iden tification tags,<br />

removal or manipula tion of the Iden tifica tion tags will void the manufacturers<br />

warranty.<br />

b) When handling the shell b vibe heat exchanger, spe ci al care should<br />

be taken to avoid dropping the unit since mishandling could cause the<br />

heat exchanger to crack and leak exte rna lly. Mishandling of the unit Is<br />

not covered under the manufac turers warranty. All units we shipped with<br />

par ti al woodreonugated cardboard containers for safe handling.<br />

c) Storage: American Indust rial heat exchange rs are p ro tected against<br />

the elements during shipment t the heat exchanger cannot be Installed<br />

and phi Into operators Immediately upon re ce ipt, certain precautions a re<br />

required to preve nt deterioration during storage. The respons ibil<br />

ity lot<br />

Integrity of the heat exc hanger(s) is assum ed by the user. Ame rican<br />

Industrial will not be resporrale for damage, co rr osion, or other deterioratiad<br />

of the heat exchanger during transit or sto rage.<br />

Proper storage practices are Important when considering the high coals of<br />

repair or replacement, and the possible delays for Henn width require long<br />

lead tines for manufacture. The following li<br />

sted practices are provided<br />

sdefy as a convenience to the user, who stint make the ir<br />

own decision<br />

on whether to use a ll or any of them.<br />

I) Heat exdrenge rs not to be placed In Immediate se rv ice, require precautionary<br />

to preve nt co rr osion orcontarninsdon.<br />

2) Heat exchange rs made of ferrous mate ri als, may be pressure-tested<br />

using compress ed air at the taciory. Residual off coa li<br />

ng on the Inside<br />

surfaces of the heat exchanger(s) as a resu lt of ushing does not<br />

the possibil ly of Internal m c orro sion. Upon receipt, fill<br />

the heat<br />

exc angier(s) w ith the app ro priate grade of oil or aptly a corrosion<br />

preven ting In hi<br />

bitor for storage.<br />

3) Corrosion protection compounds lot Inte ri or surfaces for lag tern<br />

storage or other applica tions are app lied solely at is request of aurom<br />

m Upon request, American Indus trial can p ro vide a customer<br />

approved corrosion preventative t ava il able when Included In the<br />

A SP -----Single Pass<br />

..^_^._..-Two Pass<br />

___.._...__Four Pass<br />

ONE PASS TWO PASS FOUR PASS<br />

o ri<br />

ginal purchase order specifications.<br />

4) Remove all did, water. Ice, or snow and wipe d ry before moving heat<br />

exchanger(s) Into storage. Heat exchange rs are generally s hipped<br />

empty, open drain plugs to remove any aocumufaled condensation<br />

moistu re, then reseal. Accumula ti on of moisture usua ll<br />

y Indicates<br />

corrosion has already sta rt ed and reme dial ac ti on should be taken.<br />

5) Store In a covered, envi ro nmentally stable area The Ideal sto rage<br />

environment for heat exchange rs Is In a dry, bw-Ixxddi ty abnosplhere<br />

which Is sealed to p revent the ent ry of blowing dust rain, or snow.<br />

Maintain In stmospfhedc tempe ratures between70`Fand 105°F (large<br />

temperature swings may cause condensation and m oisture to form<br />

on steel components, t hreads, shell, etc-) Use thermomete rs and<br />

humi dity Indicators and maintain the atmosphere at 40% relative<br />

humidity, or lower.<br />

d) Standard Emmet Coaling: American Indust ri al provides Its standard<br />

products with a normal base coal of oil base air cure anamel paint The<br />

enam el paint Is applied as a tempora ry protective and esthetic coaling<br />

prior to shipment. Wh il<br />

e the standard enamel coa ti ng Is du ra ble, American<br />

Indust ri al does riot warran ty fl as a long-term finish c oating. It Is strongly<br />

suggest ed that a more durable gnat coating be app li<br />

ed after Insta ll a ti on<br />

or prior to long-term storage In a corrosive envlrdnmM to cover any<br />

accidental scratches, enhance esthetics, and further prevent corrosion.<br />

It is the responsibility of the customer to provide regular mai ntenance<br />

against ch ip s. scratches, etc_ and regular touch up mainte nance must<br />

be p ro vided for long-tern benefits and co rrosion prevention.<br />

e) Special Coatings: American Indust ri al offe rs as customer options,<br />

Afr-Dry Epoxy, and Hereslte (Alt-Dry Phenol ic) coalings at addi ti on al<br />

cost. Ame ri can In dust ri al oilers special coa ti ngs teal request. however<br />

American Industrial does not wa rr anty coa ti ngs to be a pernenert solulion<br />

for any equipment against corosion. 0 is the responstb lity d Ina<br />

tusk-- ..,ratcthes.e1c.—<br />

and' Attachment 9 -turn benef it<br />

s<br />

and<br />

Cola No.:<br />

9Ar Rev.No.:<br />

Insta<br />

deal{ Sheet<br />

servk<br />

exd<br />

Pan Originator<br />

0w Date:<br />

^awn^r,." Wmke "w. Cheated by.<br />

Copy right O 2004 American kxknuW Heal Transfer, the 8903 Pe 173af Lwow Date'<br />

W'D<br />

145579 V-CA-004<br />

1 pedslouddbe<br />

9 of 10<br />

I g of system<br />

Oy.Verity lbe<br />

n AV- o r<br />

_. -- -eti a tube cheat<br />

it loo within the<br />

anger, contact<br />

-676