0 - Hanford Site

0 - Hanford Site

0 - Hanford Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

RPP-24544 REV ]d<br />

CS & STC Series installation & maintenance<br />

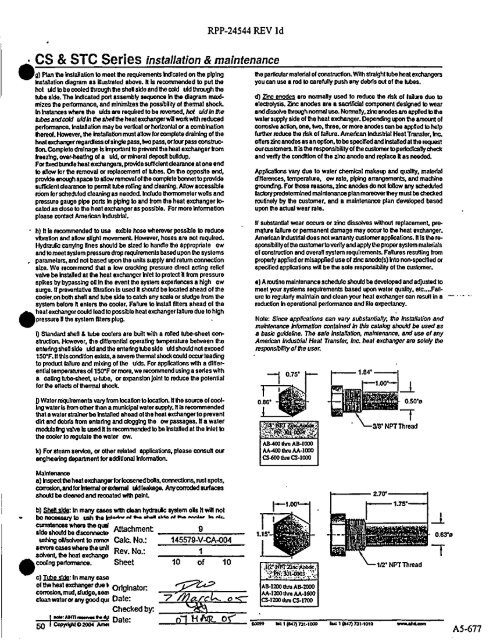

g) Flan the installation to meet the requirements Indicated on the piping<br />

Ins'allation diagram as i llustrated above. If Is recommended to put the<br />

tot uld b be cooled through the she lf side and the c old uld through the<br />

tube side. The Indicated port assembly sequence In the diagram max&<br />

mizes the performance. and moirrdzes the possib ility of thermal shock<br />

In instances where the uids we required to be reversed, trot ndd In the<br />

Mesandeold uldIn Oesheathe heat exchangerwll work with reduced<br />

pe rformance. Insta ll<br />

ation may be ver tical or ho rizontal or a combina tion<br />

thereat. However, the Installation must allow forcomplete draining of the<br />

heat exchanger regar dl<br />

ess at single pass. two pass, orIO rpass constru c.<br />

km Complete drainage Is Important to p re vent the heat exchanger from<br />

keezing, overheating at a old. or mineral deposit buildup.<br />

For fixed burde heat exchangers, provide sutaclentdearance atone end<br />

to allow or the removal or replacement of tu bes. On the opposite end,<br />

provide anaghapace to removal of the compote bo nn et to provide<br />

sufficient clearance to perm it<br />

bibs ro il<br />

ing and cleaning. Aloes accessible<br />

room for scheduled cleaning as needed. In cl<br />

ude thermometer wells and<br />

pressure gauge pipe pods in pip in g 10 and from the heat exchanger lo.<br />

catedas dose o the heat exchanger as possible. For more lnfonnaaon<br />

please contact American Industrial.<br />

• h) h is recommended to use exible hose whe rever poss ib<br />

le to reduce<br />

vbm0on and aloes slight movemen t. However, hoses are not re quired.<br />

Hydrau lic ca r rying Ines should be sized to handle the approp ri ate ow<br />

and o meetsyslem p ressu re drop requiremen ts based upon the systems<br />

paramete rs, and not based upon the units supply and return connec ti<br />

on<br />

size. We recommend th<br />

at a low cracking pressure direct a cting relief<br />

vain be Installed at the heat exchanger Wet to prote ct I kom pressure<br />

spikes by bypassing of In the event the system expe ri ences a high ow<br />

surge. It preventat iv e Duration Is used I should be located ahead of the<br />

cooler.on both then and tube side to catch any scale or sludge Imm the<br />

system before it<br />

the coder. Falum to inrstan l it<br />

ers ahead of the<br />

heat exchanger could lead to possible heat exchanger fa il u re due to high<br />

pressure I the system filters plug.<br />

g Standard shag b tube coolers are built wi th a mned tube-sheet corn<br />

struc tion However, the differential operating temperature between the<br />

en leringshelslde uldandtheenteringlubeslda uldshoutdnotexcoed<br />

1504F. It this condition exists, a seve re thermal shock could occ ur leading<br />

to product failure and mixng of the uids. For appl ic a tions with a differential<br />

temperatures of 150'F or more, we recoavnend using a sedes w ith<br />

a calling tube-sheet, u-tube, or expansion Joint to reduce the poten ti al<br />

for the e ffec ts of thermal shock<br />

0 Water requiremen ts vary from loca ti on to location. 0 the source of coalfrig<br />

waters from otter than a municipal water supply, It Is recomnended<br />

that a water "nor be insta ll ed ahead of the heal exchang er to p revent<br />

dirt and debds from entering and dogging the ow passages. I a water<br />

modtdallrg valve Is used it recommended to be Insta lled at the Inlet to<br />

the tooter to reg ulate the water ow.<br />

k) For steam ser vice, or other related applications, please consul our<br />

enginee ri<br />

ng depa rtment for additional Information<br />

Maintenance<br />

a) ktspedthe heats changerforloosenedbans, connections, rust spots,<br />

corradmandfor klemd orederrel uldleakage.A4ryconodedeu rtaces<br />

sho ul d be cleaned and recoated w it h palnL<br />

the panicutarmate rial of construction. With straight tube heat exchangers<br />

you can use a rod to ca refully push any deb ris out of the tubes.<br />

d) Zinc erodes am normally used to reduce the dsk of tallure due to<br />

electrolysis. Zinc anodes are a sac rificial component designed to we ar<br />

and dissohre through normal use. Nannaly, zinc anodes are applied to the<br />

water supply side of the heat exchanger. Depe nrIng upon the amount of<br />

corrosive action, one, two. three, or more anodes can be appled to<br />

fur th<br />

er re duce the risk of fa llure. American Industrial Heal Transfer, Inc.<br />

offers zinc anodes as an option, to specified and Installed at the request<br />

ourdrsromers. his the responsibil yof the cusloner to pedodlcaay deck<br />

and verify the condition of the zinc anode and replace It as needed.<br />

Applications va ry due to water chem ic al makeup and quality, material<br />

diffe rences. temperature. ow ra te, piping a rr angements, and machine<br />

grounding. For Rose reasons, zinc anodes do not billow arty scheduled<br />

tacbry predetermined maintenance plan moreover Ineymust be checked<br />

rou ti nely by the customer, and a maintenance plan deve loped based<br />

upon the actual wear rate.<br />

It substantial wear occurs or zinc dissolves without replacement, premature<br />

tailum or permane nt damage may o ccur to the heat exchanger.<br />

Ame ri can Indust ri al does riot warranty tustomerapp li<br />

cations. h is the responsib<br />

iliyof the customer to verify and apply the proper system mate rials<br />

of construction and overa ll system requiromens. Failures resulting from<br />

property app li<br />

ed or misapplied use of zinc anodes) Into non•specitied or<br />

specified app lic<br />

ations wi ll be the sole responsib il ity of the cusomer.<br />

e) A routine maintenance schedule sho ul d be developed and ad)usted to<br />

meet your systems requirements based upon water quality, etc .... Fail.<br />

ure to regula rly maintain end clean your heat exchanger can result In a —<br />

reduc ti on In operational pedomianee and lie expectancy.<br />

Note: Since applications can va ry subs tantially, the Installa tion and<br />

maintenance InlonnaOon contained In Mats catalog should be used as<br />

a basic guideline. The sate Insta ll<br />

ation, maintenan ce, and use of any<br />

American IndusMat Heat Transfer. Inc. beat exchanger are soley Me<br />

responslbdiry of the user.<br />

O.aG'<br />

•—'•^ 0.75'<br />

II +,_<br />

A9-a00 dxo AB-1000<br />

M