Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HEATING FILTER BALL VALVES<br />

BRASS NICKEL PLATED<br />

TECHNICAL DATA SPECIFICATION u 2-piece medium weight model<br />

Body: Brass CW617N nickel plated u Threaded ends acc. to DIN <strong>EN</strong> ISO 228-1<br />

Body cap: Brass CW617N nickel plated u Integrated dirt strainer AISI304-MW 0,5 mm<br />

Ball: Brass CW614N chrome plated u Dirt strainer can be cleaned during the operation<br />

Ball seat:<br />

PTFE<br />

Stem: Brass CW614N nickel plated APPLICATION Water (not according to DVGW DIN 1988),<br />

Stem packing: PTFE | O-Ring FKM with packing gland heating, greases, diesel, lubricating oils, fuels,<br />

Medium temperature: -20°C up to +150°C pressure dependent solvents, alkalis, weak alkalis and acids,<br />

Pressure rating: Max. 40 bar temperature dependent heating water mixture with glycol.<br />

Accessories and spare handles can be found from page 166 onwards.<br />

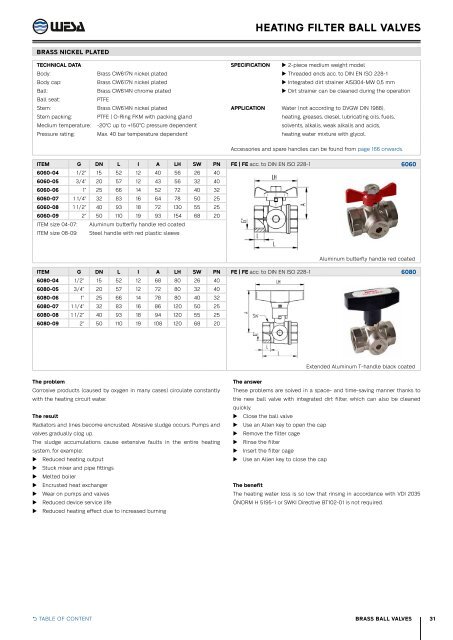

ITEM G DN L I A LH SW PN FE | FE acc. to DIN <strong>EN</strong> ISO 228-1 6060<br />

6060-04 1/2" 15 52 12 40 56 26 40<br />

6060-05 3/4" 20 57 12 43 56 32 40<br />

6060-06 1" 25 66 14 52 72 40 32<br />

6060-07 1 1/4" 32 83 16 64 78 50 25<br />

6060-08 1 1/2" 40 93 18 72 130 55 25<br />

6060-09 2" 50 110 19 93 154 68 20<br />

ITEM size 04-07: Aluminum butterfly handle red coated<br />

ITEM size 08-09: Steel handle with red plastic sleeve<br />

Aluminum butterfly handle red coated<br />

ITEM G DN L I A LH SW PN FE | FE acc. to DIN <strong>EN</strong> ISO 228-1 6080<br />

6080-04 1/2" 15 52 12 68 80 26 40<br />

6080-05 3/4" 20 57 12 72 80 32 40<br />

6080-06 1" 25 66 14 78 80 40 32<br />

6080-07 1 1/4" 32 83 16 86 120 50 25<br />

6080-08 1 1/2" 40 93 18 94 120 55 25<br />

6080-09 2" 50 110 19 108 120 68 20<br />

Extended Aluminum T-handle black coated<br />

The problem<br />

Corrosive products (caused by oxygen in many cases) circulate constantly<br />

with the heating circuit water.<br />

The result<br />

Radiators and lines become encrusted. Abrasive sludge occurs. Pumps and<br />

valves gradually clog up.<br />

The sludge accumulations cause extensive faults in the entire heating<br />

system, for example:<br />

u Reduced heating output<br />

u Stuck mixer and pipe fittings<br />

u Melted boiler<br />

u Encrusted heat exchanger<br />

u Wear on pumps and valves<br />

u Reduced device service life<br />

u Reduced heating effect due to increased burning<br />

The answer<br />

These problems are solved in a space- and time-saving manner thanks to<br />

the new ball valve with integrated dirt filter, which can also be cleaned<br />

quickly.<br />

u Close the ball valve<br />

u Use an Allen key to open the cap<br />

u Remove the filter cage<br />

u Rinse the filter<br />

u Insert the filter cage<br />

u Use an Allen key to close the cap<br />

The benefit<br />

The heating water loss is so low that rinsing in accordance with VDI 2035<br />

ÖNORM H 5195-1 or SWKI Directive BT102-01 is not required.<br />

O TABLE OF CONT<strong>EN</strong>T<br />

BRASS BALL VALVES<br />

31