Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

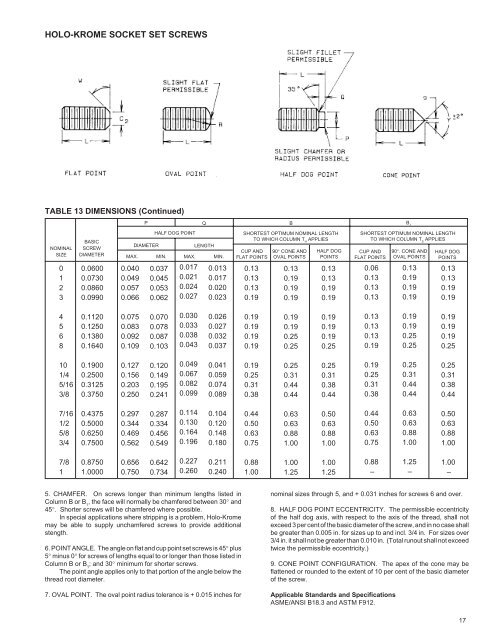

HOLO-KROME SOCKET SET SCREWS<br />

TABLE 13 DIMENSIONS (Continued)<br />

NOMINAL<br />

SIZE<br />

0<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

8<br />

10<br />

1/4<br />

5/16<br />

3/8<br />

7/16<br />

1/2<br />

5/8<br />

3/4<br />

7/8<br />

1<br />

BASIC<br />

SCREW<br />

DIAMETER<br />

0.0600<br />

0.0730<br />

0.0860<br />

0.0990<br />

0.1120<br />

0.1250<br />

0.1380<br />

0.1640<br />

0.1900<br />

0.2500<br />

0.3125<br />

0.3750<br />

0.4375<br />

0.5000<br />

0.6250<br />

0.7500<br />

0.8750<br />

1.0000<br />

P Q<br />

DIAMETER<br />

MAX. MIN.<br />

0.040<br />

0.049<br />

0.057<br />

0.066<br />

0.075<br />

0.083<br />

0.092<br />

0.109<br />

0.127<br />

0.156<br />

0.203<br />

0.250<br />

0.297<br />

0.344<br />

0.469<br />

0.562<br />

0.656<br />

0.750<br />

HALF DOG POINT<br />

0.037<br />

0.045<br />

0.053<br />

0.062<br />

0.070<br />

0.078<br />

0.087<br />

0.103<br />

0.120<br />

0.149<br />

0.195<br />

0.241<br />

0.287<br />

0.334<br />

0.456<br />

0.549<br />

0.642<br />

0.734<br />

LENGTH<br />

MAX. MIN.<br />

0.017<br />

0.021<br />

0.024<br />

0.027<br />

0.030<br />

0.033<br />

0.038<br />

0.043<br />

0.049<br />

0.067<br />

0.082<br />

0.099<br />

0.114<br />

0.130<br />

0.164<br />

0.196<br />

0.227<br />

0.260<br />

0.013<br />

0.017<br />

0.020<br />

0.023<br />

0.026<br />

0.027<br />

0.032<br />

0.037<br />

0.041<br />

0.059<br />

0.074<br />

0.089<br />

0.104<br />

0.120<br />

0.148<br />

0.180<br />

0.211<br />

0.240<br />

5. CHAMFER. On screws longer than minimum lengths listed in<br />

Column B or B 1 , the face will normally be chamfered between 30° and<br />

45°. Shorter screws will be chamfered where possible.<br />

In special applications where stripping is a problem, <strong>Holo</strong>-<strong>Krome</strong><br />

may be able to supply unchamfered screws to provide additional<br />

stength.<br />

6. POINT ANGLE. The angle on flat and cup point set screws is 45° plus<br />

5° minus 0° for screws of lengths equal to or longer than those listed in<br />

Column B or B 1 ; and 30° minimum for shorter screws.<br />

The point angle applies only to that portion of the angle below the<br />

thread root diameter.<br />

7. OVAL POINT. The oval point radius tolerance is + 0.015 inches for<br />

B<br />

SHORTEST OPTIMUM NOMINAL LENGTH<br />

TO WHICH COLUMN T APPLIES<br />

H<br />

CUP AND<br />

FLAT POINTS<br />

0.13<br />

0.13<br />

0.13<br />

0.19<br />

0.19<br />

0.19<br />

0.19<br />

0.19<br />

0.19<br />

0.25<br />

0.31<br />

0.38<br />

0.44<br />

0.50<br />

0.63<br />

0.75<br />

0.88<br />

1.00<br />

90° CONE AND<br />

OVAL POINTS<br />

0.13<br />

0.19<br />

0.19<br />

0.19<br />

0.19<br />

0.19<br />

0.25<br />

0.25<br />

0.25<br />

0.31<br />

0.44<br />

0.44<br />

0.63<br />

0.63<br />

0.88<br />

1.00<br />

1.00<br />

1.25<br />

HALF DOG<br />

POINTS<br />

0.13<br />

0.13<br />

0.19<br />

0.19<br />

0.19<br />

0.19<br />

0.19<br />

0.25<br />

0.25<br />

0.31<br />

0.38<br />

0.44<br />

0.50<br />

0.63<br />

0.88<br />

1.00<br />

1.00<br />

1.25<br />

CUP AND<br />

FLAT POINTS<br />

nominal sizes through 5, and + 0.031 inches for screws 6 and over.<br />

8. HALF DOG POINT ECCENTRICITY. The permissible eccentricity<br />

of the half dog axis, with respect to the axis of the thread, shall not<br />

exceed 3 per cent of the basic diameter of the screw, and in no case shall<br />

be greater than 0.005 in. for sizes up to and incl. 3/4 in. For sizes over<br />

3/4 in. it shall not be greater than 0.010 in. (Total runout shall not exceed<br />

twice the permissible eccentricity.)<br />

9. CONE POINT CONFIGURATION. The apex of the cone may be<br />

flattened or rounded to the extent of 10 per cent of the basic diameter<br />

of the screw.<br />

Applicable Standards and Specifications<br />

ASME/ANSI B18.3 and ASTM F912.<br />

B 1<br />

SHORTEST OPTIMUM NOMINAL LENGTH<br />

TO WHICH COLUMN T S APPLIES<br />

0.06<br />

0.13<br />

0.13<br />

0.13<br />

0.13<br />

0.13<br />

0.13<br />

0.19<br />

0.19<br />

0.25<br />

0.31<br />

0.38<br />

0.44<br />

0.50<br />

0.63<br />

0.75<br />

0.88<br />

–<br />

90°. CONE AND<br />

OVAL POINTS<br />

0.13<br />

0.19<br />

0.19<br />

0.19<br />

0.19<br />

0.19<br />

0.25<br />

0.25<br />

0.25<br />

0.31<br />

0.44<br />

0.44<br />

0.63<br />

0.63<br />

0.88<br />

1.00<br />

1.25<br />

–<br />

HALF DOG<br />

POINTS<br />

0.13<br />

0.13<br />

0.19<br />

0.19<br />

0.19<br />

0.19<br />

0.19<br />

0.25<br />

0.25<br />

0.31<br />

0.38<br />

0.44<br />

0.50<br />

0.63<br />

0.88<br />

1.00<br />

1.00<br />

–<br />

17