Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

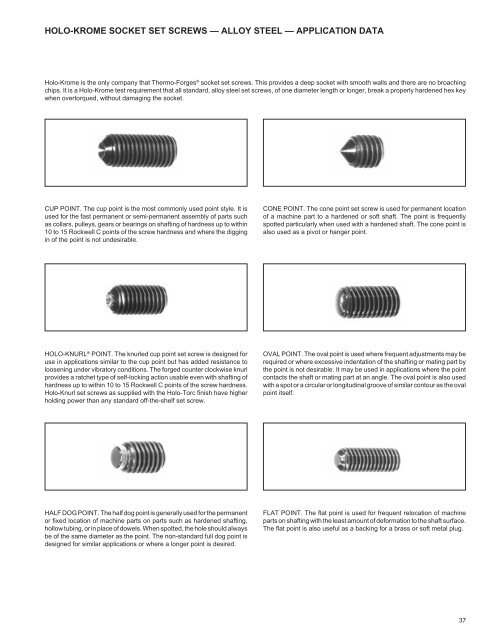

HOLO-KROME SOCKET SET SCREWS — ALLOY STEEL — APPLICATION DATA<br />

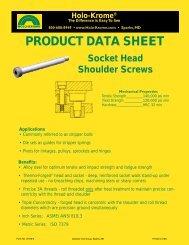

<strong>Holo</strong>-<strong>Krome</strong> is the only company that Thermo-Forges ® socket set screws. This provides a deep socket with smooth walls and there are no broaching<br />

chips. It is a <strong>Holo</strong>-<strong>Krome</strong> test requirement that all standard, alloy steel set screws, of one diameter length or longer, break a properly hardened hex key<br />

when overtorqued, without damaging the socket.<br />

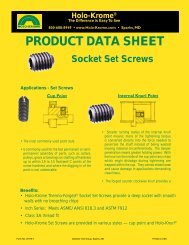

CUP POINT. The cup point is the most commonly used point style. It is<br />

used for the fast permanent or semi-permanent assembly of parts such<br />

as collars, pulleys, gears or bearings on shafting of hardness up to within<br />

10 to 15 Rockwell C points of the screw hardness and where the digging<br />

in of the point is not undesirable.<br />

HOLO-KNURL ® POINT. The knurled cup point set screw is designed for<br />

use in applications similar to the cup point but has added resistance to<br />

loosening under vibratory conditions. The forged counter clockwise knurl<br />

provides a ratchet type of self-locking action usable even with shafting of<br />

hardness up to within 10 to 15 Rockwell C points of the screw hardness.<br />

<strong>Holo</strong>-Knurl set screws as supplied with the <strong>Holo</strong>-Torc finish have higher<br />

holding power than any standard off-the-shelf set screw.<br />

HALF DOG POINT. The half dog point is generally used for the permanent<br />

or fixed location of machine parts on parts such as hardened shafting,<br />

hollow tubing, or in place of dowels. When spotted, the hole should always<br />

be of the same diameter as the point. The non-standard full dog point is<br />

designed for similar applications or where a longer point is desired.<br />

CONE POINT. The cone point set screw is used for permanent location<br />

of a machine part to a hardened or soft shaft. The point is frequently<br />

spotted particularly when used with a hardened shaft. The cone point is<br />

also used as a pivot or hanger point.<br />

OVAL POINT. The oval point is used where frequent adjustments may be<br />

required or where excessive indentation of the shafting or mating part by<br />

the point is not desirable. It may be used in applications where the point<br />

contacts the shaft or mating part at an angle. The oval point is also used<br />

with a spot or a circular or longitudinal groove of similar contour as the oval<br />

point itself.<br />

FLAT POINT. The flat point is used for frequent relocation of machine<br />

parts on shafting with the least amount of deformation to the shaft surface.<br />

The flat point is also useful as a backing for a brass or soft metal plug.<br />

37