Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

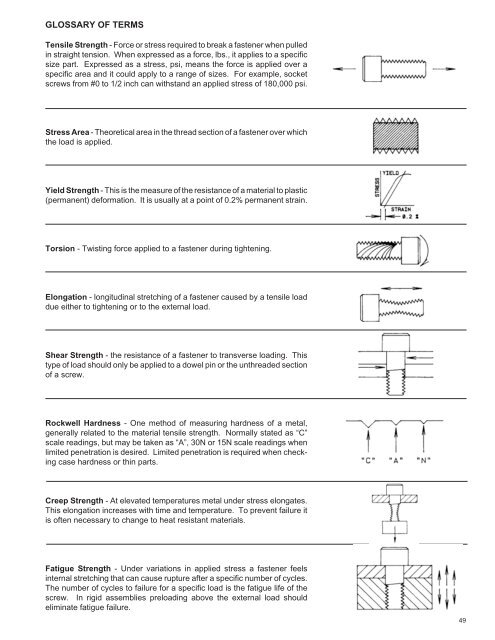

GLOSSARY OF TERMS<br />

Tensile Strength - Force or stress required to break a fastener when pulled<br />

in straight tension. When expressed as a force, lbs., it applies to a specific<br />

size part. Expressed as a stress, psi, means the force is applied over a<br />

specific area and it could apply to a range of sizes. For example, socket<br />

screws from #0 to 1/2 inch can withstand an applied stress of 180,000 psi.<br />

Stress Area - Theoretical area in the thread section of a fastener over which<br />

the load is applied.<br />

Yield Strength - This is the measure of the resistance of a material to plastic<br />

(permanent) deformation. It is usually at a point of 0.2% permanent strain.<br />

Torsion - Twisting force applied to a fastener during tightening.<br />

Elongation - longitudinal stretching of a fastener caused by a tensile load<br />

due either to tightening or to the external load.<br />

Shear Strength - the resistance of a fastener to transverse loading. This<br />

type of load should only be applied to a dowel pin or the unthreaded section<br />

of a screw.<br />

Rockwell Hardness - One method of measuring hardness of a metal,<br />

generally related to the material tensile strength. Normally stated as “C”<br />

scale readings, but may be taken as “A”, 30N or 15N scale readings when<br />

limited penetration is desired. Limited penetration is required when checking<br />

case hardness or thin parts.<br />

Creep Strength - At elevated temperatures metal under stress elongates.<br />

This elongation increases with time and temperature. To prevent failure it<br />

is often necessary to change to heat resistant materials.<br />

Fatigue Strength - Under variations in applied stress a fastener feels<br />

internal stretching that can cause rupture after a specific number of cycles.<br />

The number of cycles to failure for a specific load is the fatigue life of the<br />

screw. In rigid assemblies preloading above the external load should<br />

eliminate fatigue failure.<br />

49