Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

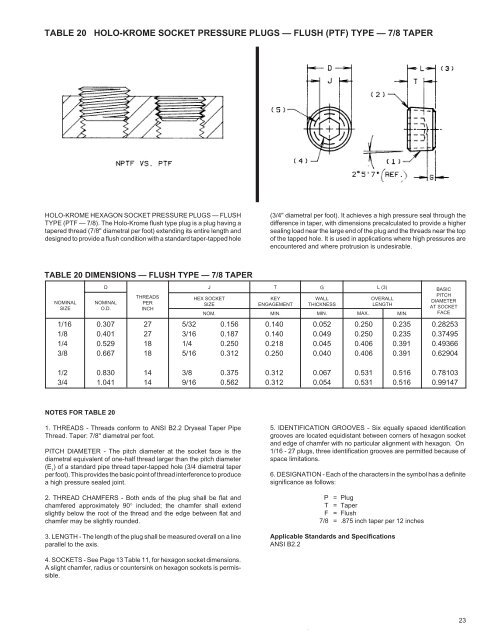

TABLE 20 HOLO-KROME SOCKET PRESSURE PLUGS — FLUSH (PTF) TYPE — 7/8 TAPER<br />

HOLO-KROME HEXAGON SOCKET PRESSURE PLUGS — FLUSH<br />

TYPE (PTF — 7/8). The <strong>Holo</strong>-<strong>Krome</strong> flush type plug is a plug having a<br />

tapered thread (7/8" diametral per foot) extending its entire length and<br />

designed to provide a flush condition with a standard taper-tapped hole<br />

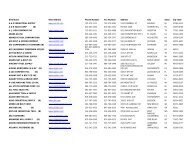

TABLE 20 DIMENSIONS — FLUSH TYPE — 7/8 TAPER<br />

NOMINAL<br />

SIZE<br />

1/16<br />

1/8<br />

1/4<br />

3/8<br />

1/2<br />

3/4<br />

NOTES FOR TABLE 20<br />

1. THREADS - Threads conform to ANSI B2.2 Dryseal Taper Pipe<br />

Thread. Taper: 7/8" diametral per foot.<br />

PITCH DIAMETER - The pitch diameter at the socket face is the<br />

diametral equivalent of one-half thread larger than the pitch diameter<br />

(E 1 ) of a standard pipe thread taper-tapped hole (3/4 diametral taper<br />

per foot). This provides the basic point of thread interference to produce<br />

a high pressure sealed joint.<br />

2. THREAD CHAMFERS - Both ends of the plug shall be flat and<br />

chamfered approximately 90° included; the chamfer shall extend<br />

slightly below the root of the thread and the edge between flat and<br />

chamfer may be slightly rounded.<br />

3. LENGTH - The length of the plug shall be measured overall on a line<br />

parallel to the axis.<br />

4. SOCKETS - See Page 13 Table 11, for hexagon socket dimensions.<br />

A slight chamfer, radius or countersink on hexagon sockets is permissible.<br />

(3/4" diametral per foot). It achieves a high pressure seal through the<br />

difference in taper, with dimensions precalculated to provide a higher<br />

sealing load near the large end of the plug and the threads near the top<br />

of the tapped hole. It is used in applications where high pressures are<br />

encountered and where protrusion is undesirable.<br />

D J<br />

T G<br />

L (3)<br />

NOMINAL<br />

O.D.<br />

0.307<br />

0.401<br />

0.529<br />

0.667<br />

0.830<br />

1.041<br />

THREADS<br />

PER<br />

INCH<br />

27<br />

27<br />

18<br />

18<br />

14<br />

14<br />

5/32<br />

3/16<br />

1/4<br />

5/16<br />

3/8<br />

9/16<br />

HEX SOCKET<br />

SIZE<br />

NOM.<br />

0.156<br />

0.187<br />

0.250<br />

0.312<br />

0.375<br />

0.562<br />

KEY<br />

ENGAGEMENT<br />

MIN.<br />

0.140<br />

0.140<br />

0.218<br />

0.250<br />

0.312<br />

0.312<br />

WALL<br />

THICKNESS<br />

OVERALL<br />

LENGTH<br />

MIN. MAX. MIN.<br />

0.052<br />

0.049<br />

0.045<br />

0.040<br />

0.067<br />

0.054<br />

0.250<br />

0.250<br />

0.406<br />

0.406<br />

0.531<br />

0.531<br />

BASIC<br />

PITCH<br />

DIAMETER<br />

AT SOCKET<br />

FACE<br />

5. IDENTIFICATION GROOVES - Six equally spaced identification<br />

grooves are located equidistant between corners of hexagon socket<br />

and edge of chamfer with no particular alignment with hexagon. On<br />

1/16 - 27 plugs, three identification grooves are permitted because of<br />

space limitations.<br />

6. DESIGNATION - Each of the characters in the symbol has a definite<br />

significance as follows:<br />

P = Plug<br />

T = Taper<br />

F = Flush<br />

7/8 = .875 inch taper per 12 inches<br />

Applicable Standards and Specifications<br />

ANSI B2.2<br />

0.235<br />

0.235<br />

0.391<br />

0.391<br />

0.516<br />

0.516<br />

0.28253<br />

0.37495<br />

0.49366<br />

0.62904<br />

0.78103<br />

0.99147<br />

23