Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

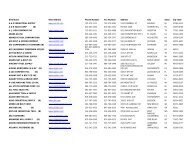

TABLE 32 ALLEN WRENCHES AND BITS<br />

MECHANICAL PROPERTIES<br />

Standard Allen Wrenches and Bits are manufactured from <strong>Holo</strong>-<strong>Krome</strong><br />

Alloy Steel, hardened by quenching in oil from the hardening temperature<br />

TABLE 32<br />

MECHANICAL PROPERTIES ALLEN WRENCHES APPLICATION DATA<br />

NOMINAL<br />

KEY OR BIT<br />

SIZE<br />

40<br />

0.028<br />

0.035<br />

0.050<br />

1/16<br />

5/64<br />

3/32<br />

7/64<br />

1/8<br />

9/64<br />

5/32<br />

3/16<br />

7/32<br />

1/4<br />

5/16<br />

3/8<br />

7/16<br />

1/2<br />

9/16<br />

5/8<br />

3/4<br />

7/8<br />

1<br />

TORSIONAL<br />

SHEAR<br />

AVERAGE<br />

(INCH-POUNDS)<br />

1.1<br />

2.3<br />

6.5<br />

11.9<br />

25.0<br />

43.0<br />

68.0<br />

98.0<br />

146.0<br />

195.0<br />

342.0<br />

535.0<br />

770.0<br />

1,600.0<br />

2,500.0<br />

4,500.0<br />

6,300.0<br />

8,750.0<br />

12,000.0<br />

19,500.0<br />

29,000.0<br />

43,500.0<br />

NOTES FOR TABLE 32<br />

TORQUE<br />

RATING<br />

(INCH-POUNDS)<br />

0.9<br />

1.8<br />

5.3<br />

10.3<br />

20.0<br />

35.0<br />

55.0<br />

82.0<br />

118.0<br />

160.0<br />

278.0<br />

440.0<br />

655.0<br />

1,275.0<br />

2,200.0<br />

3,500.0<br />

5,200.0<br />

6,500.0<br />

9,000.0<br />

15,500.0<br />

24,600.0<br />

28,800.0<br />

NOMINAL<br />

KEY OR BIT<br />

SIZE<br />

0.028<br />

0.035<br />

0.050<br />

1/16 0.062<br />

5/64 0.078<br />

3/32 0.094<br />

7/64 0.109<br />

1/8 0.125<br />

9/64 0.141<br />

5/32 0.156<br />

3/16 0.188<br />

7/32 0.219<br />

1/4 0.250<br />

5/16 0.312<br />

3/8 0.375<br />

7/16 0.438<br />

1/2 0.500<br />

9/16 0.562<br />

5/8 0.625<br />

3/4 0.750<br />

7/8 0.875<br />

1 1.000<br />

CAP SCREWS<br />

1960 SERIES<br />

—<br />

—<br />

0<br />

1<br />

2 & 3<br />

4 & 5<br />

6<br />

—<br />

8<br />

10<br />

1/4<br />

—<br />

5/16<br />

3/8<br />

7/16 & 1/2<br />

—<br />

5/8<br />

—<br />

3/4<br />

7/8 & 1<br />

1-1/8 & 1-1/4<br />

1-3/8 & 1-1/2<br />

TORSIONAL SHEAR STRENGTH. The average torsional shear strength<br />

tabulated above is the average maximum torque which standard keys and<br />

bits will transmit when tested to destruction. When so tested, failure<br />

should occur by a clean, square shear fracture.<br />

TORQUE RATING. Standard Allen Wrenches cut into bits for use in<br />

torque wrenches will transmit the above torques.<br />

and tempered to a minimum hardness of HRC 45 at the surface to provide<br />

the following torsional properties:<br />

FLAT<br />

COUNTERSUNK<br />

HEAD<br />

CAP SCREWS<br />

—<br />

0<br />

1 & 2<br />

3 & 4<br />

5 & 6<br />

8<br />

—<br />

10<br />

—<br />

1/4<br />

5/16<br />

3/8<br />

7/16<br />

1/2<br />

5/8<br />

—<br />

3/4<br />

7/8<br />

1<br />

1-1/8<br />

1-1/4 & 1-3/8<br />

1-1/2<br />

BUTTON<br />

HEAD<br />

CAP SCREWS<br />

NOMINAL SCREW SIZES<br />

—<br />

0<br />

1 & 2<br />

3 & 4<br />

5 & 6<br />

8<br />

—<br />

10<br />

—<br />

1/4<br />

5/16<br />

3/8<br />

—<br />

1/2<br />

5/8<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

SHOULDER<br />

SCREWS<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

1/4<br />

—<br />

5/16<br />

3/8<br />

—<br />

1/2<br />

5/8<br />

3/4<br />

—<br />

1<br />

—<br />

1-1/4<br />

—<br />

1-1/2<br />

1-3/4<br />

SET<br />

SCREWS<br />

0<br />

1 & 2<br />

3 & 4<br />

5 & 6<br />

8<br />

10<br />

—<br />

1/4<br />

—<br />

5/16<br />

3/8<br />

7/16<br />

1/2<br />

5/8<br />

3/4<br />

—<br />

7/8<br />

1 & 1-1/8<br />

1-1/4 & 1-3/8<br />

1-1/2<br />

—<br />

1-3/4 & 2<br />

PRESSURE<br />

PLUGS<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

1/16<br />

1/8<br />

—<br />

1/4<br />

3/8<br />

1/2<br />

—<br />

—<br />

3/4<br />

1<br />

1-1/4<br />

—<br />

1-1/2, 2<br />

These torque values are the average torque required to develop a<br />

permanent visible twist of not more than 10° in bits which have one inch<br />

of hexagon exposed between the torque wrench and the socket. These<br />

are also the torque values which keys transmit when the short arm is<br />

inserted in a socket and the long arm is deflected or bent through an angle<br />

of 25 to 30° by the application of force near the end of the long arm. These<br />

are the torque ratings from Federal Specification GGG-K-275D, Amend.<br />

1.