Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

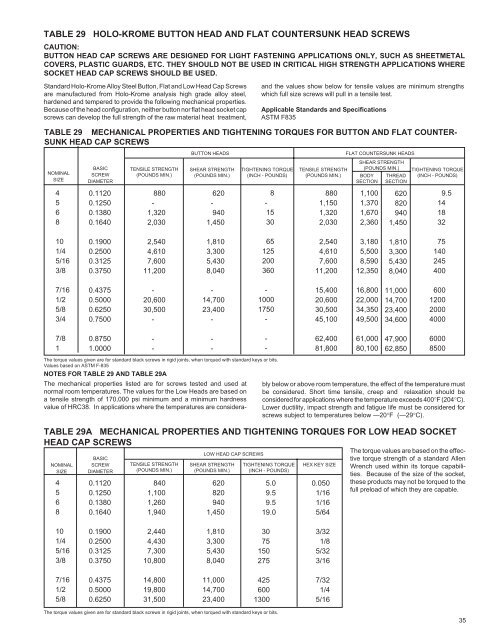

TABLE 29 HOLO-KROME BUTTON HEAD AND FLAT COUNTERSUNK HEAD SCREWS<br />

CAUTION:<br />

BUTTON HEAD CAP SCREWS ARE DESIGNED FOR LIGHT FASTENING APPLICATIONS ONLY, SUCH AS SHEETMETAL<br />

COVERS, PLASTIC GUARDS, ETC. THEY SHOULD NOT BE USED IN CRITICAL HIGH STRENGTH APPLICATIONS WHERE<br />

SOCKET HEAD CAP SCREWS SHOULD BE USED.<br />

Standard <strong>Holo</strong>-<strong>Krome</strong> Alloy Steel Button, Flat and Low Head Cap Screws<br />

are manufactured from <strong>Holo</strong>-<strong>Krome</strong> analysis high grade alloy steel,<br />

hardened and tempered to provide the following mechanical properties.<br />

Because of the head configuration, neither button nor flat head socket cap<br />

screws can develop the full strength of the raw material heat treatment,<br />

4<br />

5<br />

6<br />

8<br />

10<br />

1/4<br />

5/16<br />

3/8<br />

7/16<br />

1/2<br />

5/8<br />

3/4<br />

7/8<br />

1<br />

0.1120<br />

0.1250<br />

0.1380<br />

0.1640<br />

0.1900<br />

0.2500<br />

0.3125<br />

0.3750<br />

0.4375<br />

0.5000<br />

0.6250<br />

0.7500<br />

0.8750<br />

1.0000<br />

TENSILE STRENGTH<br />

(POUNDS MIN.)<br />

BUTTON HEADS<br />

SHEAR STRENGTH<br />

(POUNDS MIN.)<br />

and the values show below for tensile values are minimum strengths<br />

which full size screws will pull in a tensile test.<br />

Applicable Standards and Specifications<br />

ASTM F835<br />

TABLE 29 MECHANICAL PROPERTIES AND TIGHTENING TORQUES FOR BUTTON AND FLAT COUNTER-<br />

SUNK HEAD CAP SCREWS<br />

NOMINAL<br />

SIZE<br />

880<br />

-<br />

1,320<br />

2,030<br />

2,540<br />

4,610<br />

7,600<br />

11,200<br />

-<br />

20,600<br />

30,500<br />

-<br />

-<br />

-<br />

620<br />

-<br />

940<br />

1,450<br />

1,810<br />

3,300<br />

5,430<br />

8,040<br />

-<br />

14,700<br />

23,400<br />

-<br />

-<br />

-<br />

TIGHTENING TORQUE<br />

(INCH - POUNDS)<br />

8<br />

-<br />

15<br />

30<br />

65<br />

125<br />

200<br />

360<br />

-<br />

1000<br />

1750<br />

-<br />

The torque values given are for standard black screws in rigid joints, when torqued with standard keys or bits.<br />

Values based on ASTM F-835<br />

NOTES FOR TABLE 29 AND TABLE 29A<br />

The mechanical properties listed are for screws tested and used at<br />

normal room temperatures. The values for the Low Heads are based on<br />

a tensile strength of 170,000 psi minimum and a minimum hardness<br />

value of HRC38. In applications where the temperatures are considera-<br />

4<br />

5<br />

6<br />

8<br />

10<br />

1/4<br />

5/16<br />

3/8<br />

7/16<br />

1/2<br />

5/8<br />

0.1120<br />

0.1250<br />

0.1380<br />

0.1640<br />

0.1900<br />

0.2500<br />

0.3125<br />

0.3750<br />

0.4375<br />

0.5000<br />

0.6250<br />

840<br />

1,100<br />

1,260<br />

1,940<br />

2,440<br />

4,430<br />

7,300<br />

10,800<br />

14,800<br />

19,800<br />

31,500<br />

620<br />

820<br />

940<br />

1,450<br />

1,810<br />

3,300<br />

5,430<br />

8,040<br />

11,000<br />

14,700<br />

23,400<br />

-<br />

-<br />

TENSILE STRENGTH<br />

(POUNDS MIN.)<br />

880<br />

1,150<br />

1,320<br />

2,030<br />

2,540<br />

4,610<br />

7,600<br />

11,200<br />

15,400<br />

20,600<br />

30,500<br />

45,100<br />

62,400<br />

81,800<br />

FLAT COUNTERSUNK HEADS<br />

SHEAR STRENGTH<br />

(POUNDS MIN.)<br />

BODY THREAD<br />

SECTION SECTION<br />

1,100<br />

1,370<br />

1,670<br />

2,360<br />

3,180<br />

5,500<br />

8,590<br />

12,350<br />

16,800<br />

22,000<br />

34,350<br />

49,500<br />

61,000<br />

80,100<br />

620<br />

820<br />

940<br />

1,450<br />

1,810<br />

3,300<br />

5,430<br />

8,040<br />

11,000<br />

14,700<br />

23,400<br />

34,600<br />

47,900<br />

62,850<br />

TIGHTENING TORQUE<br />

(INCH - POUNDS)<br />

9.5<br />

14<br />

18<br />

32<br />

75<br />

140<br />

245<br />

400<br />

600<br />

1200<br />

2000<br />

4000<br />

6000<br />

8500<br />

bly below or above room temperature, the effect of the temperature must<br />

be considered. Short time tensile, creep and relaxation should be<br />

considered for applications where the temperature exceeds 400°F (204°C).<br />

Lower ductility, impact strength and fatigue life must be considered for<br />

screws subject to temperatures below —20°F (—29°C).<br />

TABLE 29A MECHANICAL PROPERTIES AND TIGHTENING TORQUES FOR LOW HEAD SOCKET<br />

HEAD CAP SCREWS<br />

NOMINAL<br />

SIZE<br />

BASIC<br />

SCREW<br />

DIAMETER<br />

BASIC<br />

SCREW<br />

DIAMETER<br />

TENSILE STRENGTH<br />

(POUNDS MIN.)<br />

LOW HEAD CAP SCREWS<br />

SHEAR STRENGTH<br />

(POUNDS MIN.)<br />

TIGHTENING TORQUE<br />

(INCH - POUNDS)<br />

5.0<br />

9.5<br />

9.5<br />

19.0<br />

30<br />

75<br />

150<br />

275<br />

425<br />

600<br />

1300<br />

The torque values given are for standard black screws in rigid joints, when torqued with standard keys or bits.<br />

HEX KEY SIZE<br />

0.050<br />

1/16<br />

1/16<br />

5/64<br />

3/32<br />

1/8<br />

5/32<br />

3/16<br />

7/32<br />

1/4<br />

5/16<br />

The torque values are based on the effective<br />

torque strength of a standard Allen<br />

Wrench used within its torque capabilities.<br />

Because of the size of the socket,<br />

these products may not be torqued to the<br />

full preload of which they are capable.<br />

35