Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

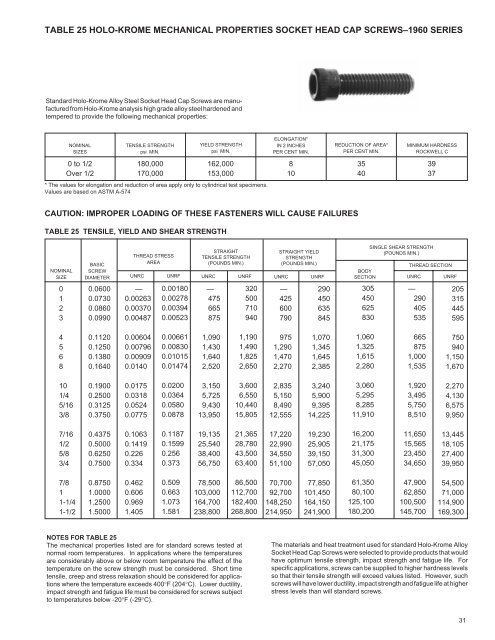

TABLE 25 HOLO-KROME MECHANICAL PROPERTIES SOCKET HEAD CAP SCREWS–1960 SERIES<br />

Standard <strong>Holo</strong>-<strong>Krome</strong> Alloy Steel Socket Head Cap Screws are manufactured<br />

from <strong>Holo</strong>-<strong>Krome</strong> analysis high grade alloy steel hardened and<br />

tempered to provide the following mechanical properties:<br />

NOMINAL<br />

SIZES<br />

0 to 1/2<br />

Over 1/2<br />

TENSILE STRENGTH<br />

psi MIN.<br />

180,000<br />

170,000<br />

YIELD STRENGTH<br />

psi MIN.<br />

162,000<br />

153,000<br />

* The values for elongation and reduction of area apply only to cylindrical test specimens.<br />

Values are based on ASTM A-574<br />

ELONGATION*<br />

IN 2 INCHES<br />

PER CENT MIN.<br />

CAUTION: IMPROPER LOADING OF THESE FASTENERS WILL CAUSE FAILURES<br />

TABLE 25 TENSILE, YIELD AND SHEAR STRENGTH<br />

NOMINAL<br />

SIZE<br />

0<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

8<br />

10<br />

1/4<br />

5/16<br />

3/8<br />

7/16<br />

1/2<br />

5/8<br />

3/4<br />

7/8<br />

1<br />

1-1/4<br />

1-1/2<br />

BASIC<br />

SCREW<br />

DIAMETER<br />

0.0600<br />

0.0730<br />

0.0860<br />

0.0990<br />

0.1120<br />

0.1250<br />

0.1380<br />

0.1640<br />

0.1900<br />

0.2500<br />

0.3125<br />

0.3750<br />

0.4375<br />

0.5000<br />

0.6250<br />

0.7500<br />

0.8750<br />

1.0000<br />

1.2500<br />

1.5000<br />

THREAD STRESS<br />

AREA<br />

UNRC UNRF<br />

—<br />

0.00263<br />

0.00370<br />

0.00487<br />

0.00604<br />

0.00796<br />

0.00909<br />

0.0140<br />

0.0175<br />

0.0318<br />

0.0524<br />

0.0775<br />

0.1063<br />

0.1419<br />

0.226<br />

0.334<br />

0.462<br />

0.606<br />

0.969<br />

1.405<br />

0.00180<br />

0.00278<br />

0.00394<br />

0.00523<br />

0.00661<br />

0.00830<br />

0.01015<br />

0.01474<br />

0.0200<br />

0.0364<br />

0.0580<br />

0.0878<br />

0.1187<br />

0.1599<br />

0.256<br />

0.373<br />

0.509<br />

0.663<br />

1.073<br />

1.581<br />

STRAIGHT<br />

TENSILE STRENGTH<br />

(POUNDS MIN.)<br />

UNRC UNRF<br />

—<br />

475<br />

665<br />

875<br />

1,090<br />

1,430<br />

1,640<br />

2,520<br />

3,150<br />

5,725<br />

9,430<br />

13,950<br />

19,135<br />

25,540<br />

38,400<br />

56,750<br />

78,500<br />

103,000<br />

164,700<br />

238,800<br />

NOTES FOR TABLE 25<br />

The mechanical properties listed are for standard screws tested at<br />

normal room temperatures. In applications where the temperatures<br />

are considerably above or below room temperature the effect of the<br />

temperature on the screw strength must be considered. Short time<br />

tensile, creep and stress relaxation should be considered for applications<br />

where the temperature exceeds 400°F (204°C). Lower ductility,<br />

impact strength and fatigue life must be considered for screws subject<br />

to temperatures below -20°F (-29°C).<br />

320<br />

500<br />

710<br />

940<br />

1,190<br />

1,490<br />

1,825<br />

2,650<br />

3,600<br />

6,550<br />

10,440<br />

15,805<br />

21,365<br />

28,780<br />

43,500<br />

63,400<br />

86,500<br />

112,700<br />

182,400<br />

268,800<br />

8<br />

10<br />

STRAIGHT YIELD<br />

STRENGTH<br />

(POUNDS MIN.)<br />

UNRC UNRF<br />

—<br />

425<br />

600<br />

790<br />

975<br />

1,290<br />

1,470<br />

2,270<br />

2,835<br />

5,150<br />

8,490<br />

12,555<br />

17,220<br />

22,990<br />

34,550<br />

51,100<br />

70,700<br />

92,700<br />

148,250<br />

214,950<br />

290<br />

450<br />

635<br />

845<br />

1,070<br />

1,345<br />

1,645<br />

2,385<br />

3,240<br />

5,900<br />

9,395<br />

14,225<br />

19,230<br />

25,905<br />

39,150<br />

57,050<br />

77,850<br />

101,450<br />

164,150<br />

241,900<br />

REDUCTION OF AREA*<br />

PER CENT MIN.<br />

35<br />

40<br />

BODY<br />

SECTION<br />

305<br />

450<br />

625<br />

830<br />

1,060<br />

1,325<br />

1,615<br />

2,280<br />

3,060<br />

5,295<br />

8,285<br />

11,910<br />

16,200<br />

21,175<br />

31,300<br />

45,050<br />

61,350<br />

80,100<br />

125,100<br />

180,200<br />

MINIMUM HARDNESS<br />

ROCKWELL C<br />

39<br />

37<br />

SINGLE SHEAR STRENGTH<br />

(POUNDS MIN.)<br />

THREAD SECTION<br />

UNRC UNRF<br />

—<br />

290<br />

405<br />

535<br />

665<br />

875<br />

1,000<br />

1,535<br />

1,920<br />

3,495<br />

5,750<br />

8,510<br />

11,650<br />

15,565<br />

23,450<br />

34,650<br />

47,900<br />

62,850<br />

100,500<br />

145,700<br />

205<br />

315<br />

445<br />

595<br />

750<br />

940<br />

1,150<br />

1,670<br />

2,270<br />

4,130<br />

6,575<br />

9,950<br />

13,445<br />

18,105<br />

27,400<br />

39,950<br />

54,500<br />

71,000<br />

114,900<br />

169,300<br />

The materials and heat treatment used for standard <strong>Holo</strong>-<strong>Krome</strong> Alloy<br />

Socket Head Cap Screws were selected to provide products that would<br />

have optimum tensile strength, impact strength and fatigue life. For<br />

specific applications, screws can be supplied to higher hardness levels<br />

so that their tensile strength will exceed values listed. However, such<br />

screws will have lower ductility, impact strength and fatigue life at higher<br />

stress levels than will standard screws.<br />

31