Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

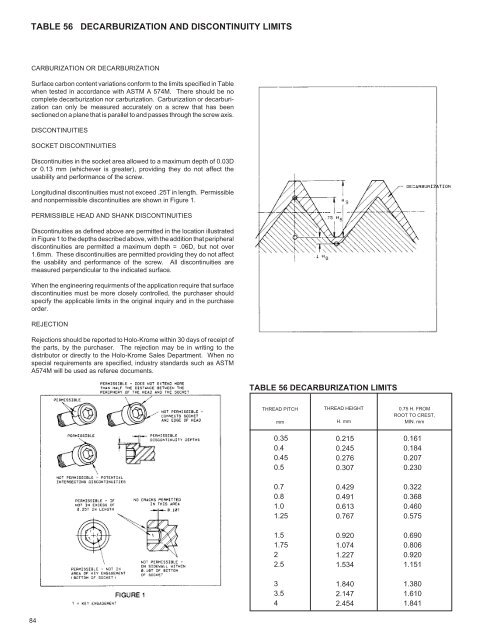

TABLE 56 DECARBURIZATION AND DISCONTINUITY LIMITS<br />

CARBURIZATION OR DECARBURIZATION<br />

Surface carbon content variations conform to the limits specified in Table<br />

when tested in accordance with ASTM A 574M. There should be no<br />

complete decarburization nor carburization. Carburization or decarburization<br />

can only be measured accurately on a screw that has been<br />

sectioned on a plane that is parallel to and passes through the screw axis.<br />

DISCONTINUITIES<br />

SOCKET DISCONTINUITIES<br />

Discontinuities in the socket area allowed to a maximum depth of 0.03D<br />

or 0.13 mm (whichever is greater), providing they do not affect the<br />

usability and performance of the screw.<br />

Longitudinal discontinuities must not exceed .25T in length. Permissible<br />

and nonpermissible discontinuities are shown in Figure 1.<br />

PERMISSIBLE HEAD AND SHANK DISCONTINUITIES<br />

Discontinuities as defined above are permitted in the location illustrated<br />

in Figure 1 to the depths described above, with the addition that peripheral<br />

discontinuities are permitted a maximum depth = .06D, but not over<br />

1.6mm. These discontinuities are permitted providing they do not affect<br />

the usability and performance of the screw. All discontinuities are<br />

measured perpendicular to the indicated surface.<br />

When the engineering requirments of the application require that surface<br />

discontinuities must be more closely controlled, the purchaser should<br />

specify the applicable limits in the original inquiry and in the purchase<br />

order.<br />

REJECTION<br />

Rejections should be reported to <strong>Holo</strong>-<strong>Krome</strong> within 30 days of receipt of<br />

the parts, by the purchaser. The rejection may be in writing to the<br />

distributor or directly to the <strong>Holo</strong>-<strong>Krome</strong> Sales Department. When no<br />

special requirements are specified, industry standards such as ASTM<br />

A574M will be used as referee documents.<br />

84<br />

FIGURE 1<br />

TABLE 56 DECARBURIZATION LIMITS<br />

THREAD PITCH<br />

mm<br />

0.35<br />

0.4<br />

0.45<br />

0.5<br />

0.7<br />

0.8<br />

1.0<br />

1.25<br />

1.5<br />

1.75<br />

2<br />

2.5<br />

3<br />

3.5<br />

4<br />

THREAD HEIGHT<br />

H. mm<br />

0.215<br />

0.245<br />

0.276<br />

0.307<br />

0.429<br />

0.491<br />

0.613<br />

0.767<br />

0.920<br />

1.074<br />

1.227<br />

1.534<br />

1.840<br />

2.147<br />

2.454<br />

0.75 H. FROM<br />

ROOT TO CREST,<br />

MIN. mm<br />

0.161<br />

0.184<br />

0.207<br />

0.230<br />

0.322<br />

0.368<br />

0.460<br />

0.575<br />

0.690<br />

0.806<br />

0.920<br />

1.151<br />

1.380<br />

1.610<br />

1.841