Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

Consolidated Tech Man - Holo-Krome

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

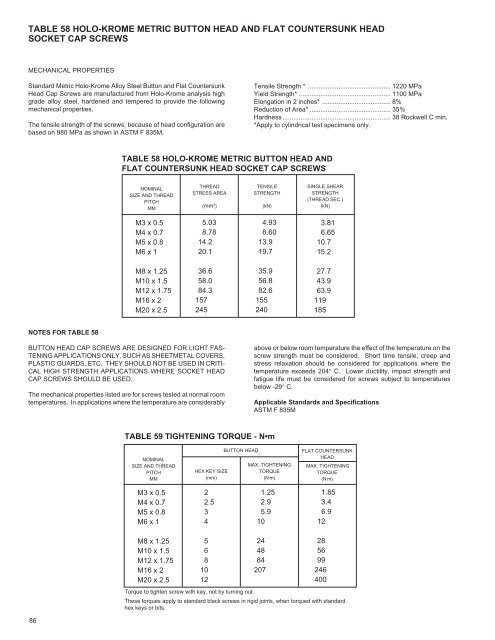

TABLE 58 HOLO-KROME METRIC BUTTON HEAD AND FLAT COUNTERSUNK HEAD<br />

SOCKET CAP SCREWS<br />

MECHANICAL PROPERTIES<br />

Standard Metric <strong>Holo</strong>-<strong>Krome</strong> Alloy Steel Button and Flat Countersunk<br />

Head Cap Screws are manufactured from <strong>Holo</strong>-<strong>Krome</strong> analysis high<br />

grade alloy steel, hardened and tempered to provide the following<br />

mechanical properties.<br />

The tensile strength of the screws, because of head configuration are<br />

based on 980 MPa as shown in ASTM F 835M.<br />

NOTES FOR TABLE 58<br />

86<br />

TABLE 58 HOLO-KROME METRIC BUTTON HEAD AND<br />

FLAT COUNTERSUNK HEAD SOCKET CAP SCREWS<br />

NOMINAL<br />

SIZE AND THREAD<br />

PITCH<br />

MM<br />

M3 x 0.5<br />

M4 x 0.7<br />

M5 x 0.8<br />

M6 x 1<br />

M8 x 1.25<br />

M10 x 1.5<br />

M12 x 1.75<br />

M16 x 2<br />

M20 x 2.5<br />

THREAD<br />

STRESS AREA<br />

(mm 2 )<br />

5.03<br />

8.78<br />

14.2<br />

20.1<br />

36.6<br />

58.0<br />

84.3<br />

157<br />

245<br />

BUTTON HEAD CAP SCREWS ARE DESIGNED FOR LIGHT FAS-<br />

TENING APPLICATIONS ONLY, SUCH AS SHEETMETAL COVERS,<br />

PLASTIC GUARDS, ETC. THEY SHOULD NOT BE USED IN CRITI-<br />

CAL HIGH STRENGTH APPLICATIONS WHERE SOCKET HEAD<br />

CAP SCREWS SHOULD BE USED.<br />

The mechanical properties listed are for screws tested at normal room<br />

temperatures. In applications where the temperature are considerably<br />

Tensile Strength * .............................................. 1220 MPa<br />

Yield Strength* ................................................... 1100 MPa<br />

Elongation in 2 inches* ...................................... 8%<br />

Reduction of Area* ............................................. 35%<br />

Hardness ............................................................ 38 Rockwell C min.<br />

*Apply to cylindrical test specimens only.<br />

TENSILE<br />

STRENGTH<br />

(kN)<br />

4.93<br />

8.60<br />

13.9<br />

19.7<br />

35.9<br />

56.8<br />

82.6<br />

155<br />

240<br />

TABLE 59 TIGHTENING TORQUE - N•m<br />

NOMINAL<br />

SIZE AND THREAD<br />

PITCH<br />

MM<br />

M3 x 0.5<br />

M4 x 0.7<br />

M5 x 0.8<br />

M6 x 1<br />

M8 x 1.25<br />

M10 x 1.5<br />

M12 x 1.75<br />

M16 x 2<br />

M20 x 2.5<br />

HEX KEY SIZE<br />

(mm)<br />

2<br />

2.5<br />

3<br />

4<br />

5<br />

6<br />

8<br />

10<br />

12<br />

BUTTON HEAD<br />

1.25<br />

2.9<br />

5.9<br />

10<br />

24<br />

48<br />

84<br />

207<br />

SINGLE SHEAR<br />

STRENGTH<br />

(THREAD SEC.)<br />

(kN)<br />

3.81<br />

6.65<br />

10.7<br />

15.2<br />

27.7<br />

43.9<br />

63.9<br />

119<br />

185<br />

1.85<br />

3.4<br />

6.9<br />

12<br />

28<br />

56<br />

99<br />

246<br />

400<br />

Torque to tighten screw with key, not by turning nut.<br />

These torques apply to standard black screws in rigid joints, when torqued with standard<br />

hex keys or bits.<br />

above or below room temperature the effect of the temperature on the<br />

screw strength must be considered. Short time tensile, creep and<br />

stress relaxation should be considered for applications where the<br />

temperature exceeds 204° C. Lower ductility, impact strength and<br />

fatigue life must be considered for screws subject to temperatures<br />

below -29° C.<br />

Applicable Standards and Specifications<br />

ASTM F 835M<br />

MAX. TIGHTENING<br />

TORQUE<br />

(N . m)<br />

FLAT COUNTERSUNK<br />

HEAD<br />

MAX. TIGHTENING<br />

TORQUE<br />

(N . m)