Etude par Sonde Atomique Tomographique de la formation de nano ...

Etude par Sonde Atomique Tomographique de la formation de nano ...

Etude par Sonde Atomique Tomographique de la formation de nano ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

tel-00751814, version 1 - 14 Nov 2012<br />

Appendixes<br />

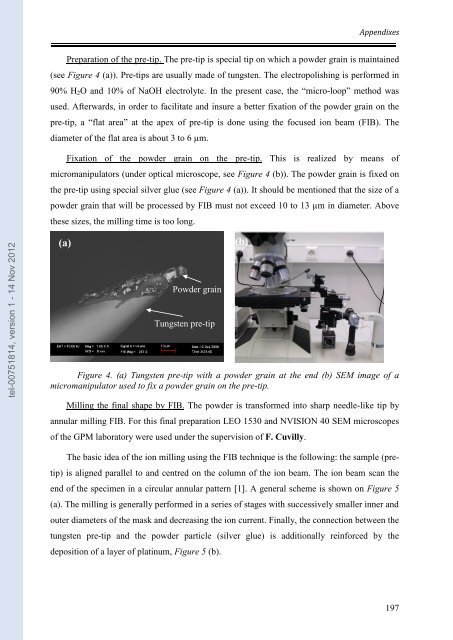

Pre<strong>par</strong>ation of the pre-tip. The pre-tip is special tip on which a pow<strong>de</strong>r grain is maintained<br />

(see Figure 4 (a)). Pre-tips are usually ma<strong>de</strong> of tungsten. The electropolishing is performed in<br />

90% H2O and 10% of NaOH electrolyte. In the present case, the “micro-loop” method was<br />

used. Afterwards, in or<strong>de</strong>r to facilitate and insure a better fixation of the pow<strong>de</strong>r grain on the<br />

pre-tip, a “f<strong>la</strong>t area” at the apex of pre-tip is done using the focused ion beam (FIB). The<br />

diameter of the f<strong>la</strong>t area is about 3 to 6 µm.<br />

Fixation of the pow<strong>de</strong>r grain on the pre-tip. This is realized by means of<br />

micromanipu<strong>la</strong>tors (un<strong>de</strong>r optical microscope, see Figure 4 (b)). The pow<strong>de</strong>r grain is fixed on<br />

the pre-tip using special silver glue (see Figure 4 (a)). It should be mentioned that the size of a<br />

pow<strong>de</strong>r grain that will be processed by FIB must not exceed 10 to 13 µm in diameter. Above<br />

these sizes, the milling time is too long.<br />

(a)<br />

Pow<strong>de</strong>r grain<br />

Tungsten pre-tip<br />

Figure 4. (a) Tungsten pre-tip with a pow<strong>de</strong>r grain at the end (b) SEM image of a<br />

micromanipu<strong>la</strong>tor used to fix a pow<strong>de</strong>r grain on the pre-tip.<br />

Milling the final shape by FIB. The pow<strong>de</strong>r is transformed into sharp needle-like tip by<br />

annu<strong>la</strong>r milling FIB. For this final pre<strong>par</strong>ation LEO 1530 and NVISION 40 SEM microscopes<br />

of the GPM <strong>la</strong>boratory were used un<strong>de</strong>r the supervision of F. Cuvilly.<br />

The basic i<strong>de</strong>a of the ion milling using the FIB technique is the following: the sample (pre-<br />

tip) is aligned <strong>par</strong>allel to and centred on the column of the ion beam. The ion beam scan the<br />

end of the specimen in a circu<strong>la</strong>r annu<strong>la</strong>r pattern [1]. A general scheme is shown on Figure 5<br />

(a). The milling is generally performed in a series of stages with successively smaller inner and<br />

outer diameters of the mask and <strong>de</strong>creasing the ion current. Finally, the connection between the<br />

tungsten pre-tip and the pow<strong>de</strong>r <strong>par</strong>ticle (silver glue) is additionally reinforced by the<br />

<strong>de</strong>position of a <strong>la</strong>yer of p<strong>la</strong>tinum, Figure 5 (b).<br />

(b)<br />

197