Etude par Sonde Atomique Tomographique de la formation de nano ...

Etude par Sonde Atomique Tomographique de la formation de nano ...

Etude par Sonde Atomique Tomographique de la formation de nano ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

tel-00751814, version 1 - 14 Nov 2012<br />

I.3. Mechanically alloyed NDS steel (MA NDS)<br />

Chapter 2. Materials, experimental and simu<strong>la</strong>tion techniques<br />

NDS steels were e<strong>la</strong>borated following two distinct ways. The first one is mechanical<br />

alloying. In this case, pre-alloyed pow<strong>de</strong>r Fe-18Cr-1W-0.14N is mechanically alloyed with<br />

0.5 wt.% of titanium hydrate (TiH2) in <strong>la</strong>boratory attritor ball mill. Mechanical alloying is<br />

performed in CEA (SRMA/LTMEX), Sac<strong>la</strong>y. Initial sizes of pre-alloyed pow<strong>de</strong>r and TiH2 are<br />

100 µm and 100 nm respectively. Parameters of milling are the following:<br />

o Atmosphere: gas argon.<br />

o Milling time: 10 hours.<br />

o Milling speed: 400 rpm.<br />

o The ratio of the mass of the balls to the pow<strong>de</strong>r mballs/mpow<strong>de</strong>r: 15.<br />

o Balls: stainless steel 440<br />

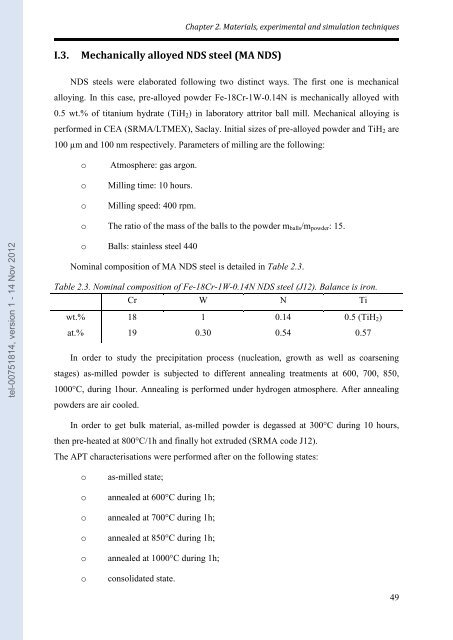

Nominal composition of MA NDS steel is <strong>de</strong>tailed in Table 2.3.<br />

Table 2.3. Nominal composition of Fe-18Cr-1W-0.14N NDS steel (J12). Ba<strong>la</strong>nce is iron.<br />

Cr W N Ti<br />

wt.% 18 1 0.14 0.5 (TiH2)<br />

at.% 19 0.30 0.54 0.57<br />

In or<strong>de</strong>r to study the precipitation process (nucleation, growth as well as coarsening<br />

stages) as-milled pow<strong>de</strong>r is subjected to different annealing treatments at 600, 700, 850,<br />

1000°C, during 1hour. Annealing is performed un<strong>de</strong>r hydrogen atmosphere. After annealing<br />

pow<strong>de</strong>rs are air cooled.<br />

In or<strong>de</strong>r to get bulk material, as-milled pow<strong>de</strong>r is <strong>de</strong>gassed at 300°C during 10 hours,<br />

then pre-heated at 800°C/1h and finally hot extru<strong>de</strong>d (SRMA co<strong>de</strong> J12).<br />

The APT characterisations were performed after on the following states:<br />

o as-milled state;<br />

o annealed at 600°C during 1h;<br />

o annealed at 700°C during 1h;<br />

o annealed at 850°C during 1h;<br />

o annealed at 1000°C during 1h;<br />

o consolidated state.<br />

49