sfogliabile_AL_n6_dicembre

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Current Affairs<br />

Figure 4:<br />

Alcoa’s research<br />

centre in<br />

Pittsburgh,<br />

renamed Arconic<br />

Technology Center<br />

(ATC), will be part<br />

of Arconic. This is<br />

the largest R&D<br />

centre in the world<br />

dedicated to light<br />

metals<br />

Figura 4:<br />

Il centro<br />

ricerche Alcoa<br />

di Pittsburgh,<br />

rinominato<br />

Arconic<br />

Technology Center<br />

(ATC), farà parte<br />

di Arconic Si tratta<br />

del maggior centro<br />

mondiale di R&D<br />

per i materiali<br />

leggeri<br />

Focus on R&D and<br />

innovative technologies<br />

Sectors where the new society will be<br />

present, as we said, are all growing fast<br />

on a global scale and demand solutions<br />

and proposals which should also be universal.Aboveall,thecoresectorsofArconicstandoutfortheirstrongneedfor<br />

Research and Development activities. An<br />

example can illustrate this aspect very<br />

well. 3D printers are more and more frequently<br />

used to manufacture aeronautical<br />

details. Alcoa, at research centre in<br />

Pittsburgh,hasdevelopedtheproduction<br />

of special details in small series using<br />

the traditional knowledge involved in<br />

forging details obtained by means of the metallurgy of powders<br />

and the new possibilities of 3D printing.<br />

It is therefore possible to supply the aeronautical industry with<br />

products not just made out of aluminium but of titanium and<br />

nickel too. This is very important news because it paves the<br />

way for the transformation in a company involved with different<br />

types of materials. This type of special “micro-productions”<br />

will typically be part of Arconic’s aeronautical business<br />

unit. A multi-material and specialist approach that is hard<br />

to find in a company concentrated on the commodity business.TheoverallArconicstructureisshowninfigure3,illustrating<br />

the main activities of the three Business Units: EPS (Engineered<br />

Products and Solutions), GRP (Global Rolled Product)<br />

and TCS (Transportation and Construction<br />

System).<br />

In order to confer a top-notch technological<br />

value to this spinoff, the Pittsburgh<br />

Centre for Research and Development<br />

(Arconic Technology Centre), that<br />

is, the world’s greatest research centre<br />

for the study of the metallurgy of aluminiumanditsalloyswillbepartofArconic.<br />

The Center’s most recent successes<br />

are linked to the development<br />

of new Aluminium-Lithium alloys for extreme<br />

applications in aeronautics; in this<br />

same sector the development of forging<br />

techniques should be recalled. In the<br />

sectorofthedevelopmentofnewalloys<br />

for car bodies, the R&D structures of Alcoa brought production<br />

using the Micromill® process to industrial level.<br />

Ford announced that for the production of the F150 Raptor<br />

pick-up in 2016, rolled products produced using Micromill, Alcoa’s<br />

continuous casting system capable of producing rolled<br />

products with a very high deformation capacity during mouldingandwitha40%improvementoftheformingprocess,will<br />

beused.TheentireMicromill“package”willofcoursebeapart<br />

of Arconic, and the Alcoa-Danieli agreement will also be part<br />

of the company.<br />

In this way the former Aluminium Company of America moves<br />

on in its process of innovation of the United States’ signature<br />

industry: automotive.<br />

❚<br />

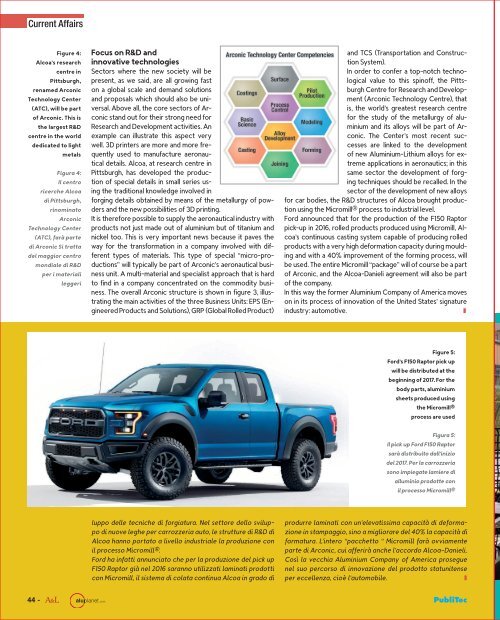

Figure 5:<br />

Ford’s F150 Raptor pick up<br />

will be distributed at the<br />

beginning of 2017. For the<br />

body parts, aluminium<br />

sheets produced using<br />

the Micromill®<br />

process are used<br />

Figura 5:<br />

IlpickupFordF150Raptor<br />

sarà distribuito dall’inizio<br />

del2017.Perlacarrozzeria<br />

sono impiegate lamiere di<br />

alluminio prodotte con<br />

il processo Micromill®<br />

luppo delle tecniche di forgiatura. Nel settore dello sviluppo<br />

di nuove leghe per carrozzeria auto, le strutture di R&D di<br />

Alcoa hanno portato a livello industriale la produzione con<br />

il processo Micromill®.<br />

Ford ha infatti annunciato che per la produzione del pick up<br />

F150 Raptor già nel 2016 saranno utilizzati laminati prodotti<br />

con Micromill, il sistema di colata continua Alcoa in grado di<br />

produrre laminati con un’elevatissima capacità di deformazione<br />

in stampaggio, sino a migliorare del 40% la capacità di<br />

formatura. L’intero “pacchetto “ Micromill farà ovviamente<br />

parte di Arconic, cui afferirà anche l’accordo Alcoa–Danieli.<br />

Così la vecchia Aluminium Company of America prosegue<br />

nel suo percorso di innovazione del prodotto statunitense<br />

per eccellenza, cioè l’automobile.<br />

❚<br />

44 -<br />

.com<br />

PubliTec