Automotive Exports December 2022

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

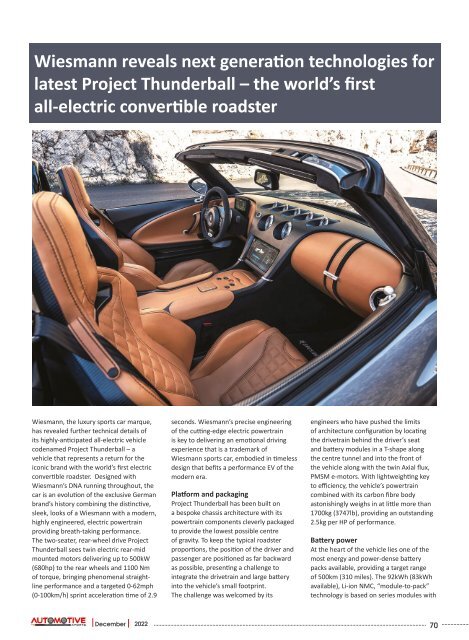

Wiesmann reveals next generation technologies for<br />

latest Project Thunderball – the world’s first<br />

all-electric convertible roadster<br />

Wiesmann, the luxury sports car marque,<br />

has revealed further technical details of<br />

its highly-anticipated all-electric vehicle<br />

codenamed Project Thunderball – a<br />

vehicle that represents a return for the<br />

iconic brand with the world’s first electric<br />

convertible roadster. Designed with<br />

Wiesmann’s DNA running throughout, the<br />

car is an evolution of the exclusive German<br />

brand’s history combining the distinctive,<br />

sleek, looks of a Wiesmann with a modern,<br />

highly engineered, electric powertrain<br />

providing breath-taking performance.<br />

The two-seater, rear-wheel drive Project<br />

Thunderball sees twin electric rear-mid<br />

mounted motors delivering up to 500kW<br />

(680hp) to the rear wheels and 1100 Nm<br />

of torque, bringing phenomenal straightline<br />

performance and a targeted 0-62mph<br />

(0-100km/h) sprint acceleration time of 2.9<br />

seconds. Wiesmann’s precise engineering<br />

of the cutting-edge electric powertrain<br />

is key to delivering an emotional driving<br />

experience that is a trademark of<br />

Wiesmann sports car, embodied in timeless<br />

design that befits a performance EV of the<br />

modern era.<br />

Platform and packaging<br />

Project Thunderball has been built on<br />

a bespoke chassis architecture with its<br />

powertrain components cleverly packaged<br />

to provide the lowest possible centre<br />

of gravity. To keep the typical roadster<br />

proportions, the position of the driver and<br />

passenger are positioned as far backward<br />

as possible, presenting a challenge to<br />

integrate the drivetrain and large battery<br />

into the vehicle’s small footprint.<br />

The challenge was welcomed by its<br />

engineers who have pushed the limits<br />

of architecture configuration by locating<br />

the drivetrain behind the driver’s seat<br />

and battery modules in a T-shape along<br />

the centre tunnel and into the front of<br />

the vehicle along with the twin Axial flux,<br />

PMSM e-motors. With lightweighting key<br />

to efficiency, the vehicle’s powertrain<br />

combined with its carbon fibre body<br />

astonishingly weighs in at little more than<br />

1700kg (3747lb), providing an outstanding<br />

2.5kg per HP of performance.<br />

Battery power<br />

At the heart of the vehicle lies one of the<br />

most energy and power-dense battery<br />

packs available, providing a target range<br />

of 500km (310 miles). The 92kWh (83kWh<br />

available), Li-ion NMC, “module-to-pack”<br />

technology is based on series modules with<br />

<strong>December</strong> <strong>2022</strong> 70