Automotive Exports December 2022

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

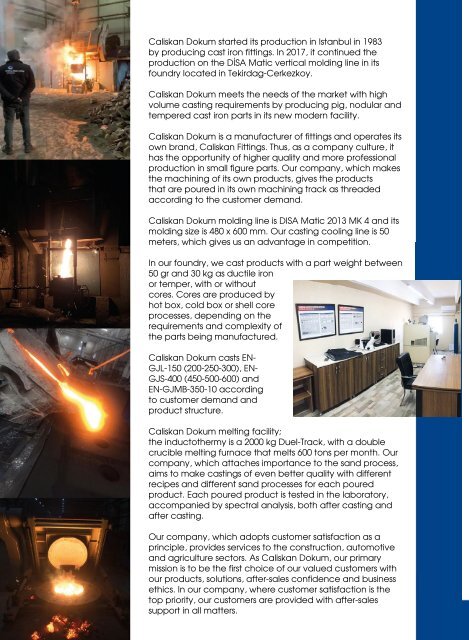

Caliskan Dokum started its production in Istanbul in 1983<br />

by producing cast iron fittings. In 2017, it continued the<br />

production on the DİSA Matic vertical molding line in its<br />

foundry located in Tekirdag-Cerkezkoy.<br />

Caliskan Dokum meets the needs of the market with high<br />

volume casting requirements by producing pig, nodular and<br />

tempered cast iron parts in its new modern facility.<br />

Caliskan Dokum is a manufacturer of fittings and operates its<br />

own brand, Caliskan Fittings. Thus, as a company culture, it<br />

has the opportunity of higher quality and more professional<br />

production in small figure parts. Our company, which makes<br />

the machining of its own products, gives the products<br />

that are poured in its own machining track as threaded<br />

according to the customer demand.<br />

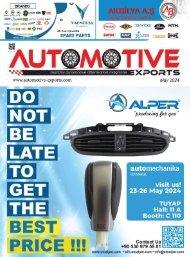

Caliskan Dokum molding line is DISA Matic 2013 MK 4 and its<br />

molding size is 480 x 600 mm. Our casting cooling line is 50<br />

meters, which gives us an advantage in competition.<br />

In our foundry, we cast products with a part weight between<br />

50 gr and 30 kg as ductile iron<br />

or temper, with or without<br />

cores. Cores are produced by<br />

hot box, cold box or shell core<br />

processes, depending on the<br />

requirements and complexity of<br />

the parts being manufactured.<br />

Caliskan Dokum casts EN-<br />

GJL-150 (200-250-300), EN-<br />

GJS-400 (450-500-600) and<br />

EN-GJMB-350-10 according<br />

to customer demand and<br />

product structure.<br />

Caliskan Dokum melting facility;<br />

the inductothermy is a 2000 kg Duel-Track, with a double<br />

crucible melting furnace that melts 600 tons per month. Our<br />

company, which attaches importance to the sand process,<br />

aims to make castings of even better quality with different<br />

recipes and different sand processes for each poured<br />

product. Each poured product is tested in the laboratory,<br />

accompanied by spectral analysis, both after casting and<br />

after casting.<br />

Our company, which adopts customer satisfaction as a<br />

principle, provides services to the construction, automotive<br />

and agriculture sectors. As Caliskan Dokum, our primary<br />

mission is to be the first choice of our valued customers with<br />

our products, solutions, after-sales confidence and business<br />

ethics. In our company, where customer satisfaction is the<br />

top priority, our customers are provided with after-sales<br />

support in all matters.