W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ADVANCE TIMING HOLE<br />

FOR CHECKING WITH<br />

NEON LIGHT<br />

ENGINE<br />

(C LOC<br />

MARK ON VERTICAL<br />

CEHTERLINE<br />

MARKED VANE<br />

ON FLYWHEEL<br />

No. 2 TERMINAL<br />

TOWER<br />

TO IGNITION<br />

COIL<br />

No. 1 TERMINAL<br />

TOWER<br />

ROTOR<br />

ROTATION<br />

ADVANCE ARM<br />

MOUNTING SCREW<br />

FLYWHEEL AIR SHROUD<br />

FLYWHEEL SCREEN<br />

F~g. 14<br />

magneto end cap is the tower toward the engine.<br />

Fig. 12.<br />

<strong>Th</strong>e magneto rotates at crankshaft speed in clockwise<br />

direction when viewing driving gear end. <strong>Th</strong>e rotor<br />

distributes one spark per revolution for each cylinder,<br />

but only the spark on compression stroke is useful.<br />

<strong>Th</strong>e other spark is wasted during the exhaust stroke.<br />

See<br />

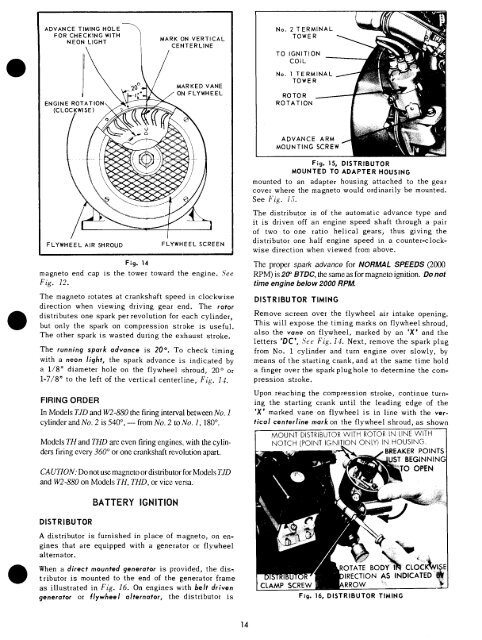

<strong>Th</strong>e running spark advance is 20 ° . To check timing<br />

with a neon light, the spark advance is indicated by<br />

a 1/8" diameter hole on the flywheel shroud, 20 ° or<br />

1-7/8" to the left of the vertical centerline, Fig. 14.<br />

FIRING<br />

ORDER<br />

In Models TJD and <strong>W2</strong>-<strong>880</strong> the firing interval between No. l<br />

cylinder and No. 2 is 540 °, -- from No. °. 2 to No. 1,180<br />

Models TH and THD are even fn-ing engines,, with the cylinders<br />

firing every 360 ° or one crankshaft revolution apart.<br />

Fig. 15, DISTRIBUTOR<br />

MOUNTED TO ADAPTER HOUSING<br />

mounted to an adapter housing attached to the gear<br />

cover where the magneto would ordinarily be mounted.<br />

See Fig. 15.<br />

<strong>Th</strong>e distributor is of the automatic advance type and<br />

it is driven off an engine speed shaft through a pair<br />

of two to one ratio helical gears, thus giving the<br />

distributor one half engine speed in a counter-clockwise<br />

direction when viewed from above.<br />

<strong>Th</strong>e proper spark advance for NORMAL SPEEDS (2000<br />

RPM) is 20 ° BTDC, the same as for magneto ignition. Do not<br />

time engine below 2000 RPM.<br />

DISTRIBUTOR TIMING<br />

Remove screen over the flywheel air intake opening.<br />

<strong>Th</strong>is will expose the timing marks on flywheel shroud,<br />

also the vane on flywheel, marked by an ’X’ and the<br />

letters ’DC’, See Fig. 14. Next, remove the spark plug<br />

from No. 1 cylinder and turn engine over slowly, by<br />

means of the starting crank, and at the same time hold<br />

a finger over the spark plughole to determine the compression<br />

stroke.<br />

Upon reaching the compression stroke, continue turning<br />

the starting crank until the leading edge of the<br />

’X’ marked vane on flywheel is in line with the vertical<br />

centerline mark on the flywheel shroud, as shown<br />

MOUNT DISTRIBUTOR WITH ROTOR IN LINE WITH<br />

NOTCH (POINT IGNITION ONLY)IN HOUSING.<br />

BREAKER POINTS<br />

CA UTION." Do not use magneto or distributor for Models TJD<br />

and <strong>W2</strong>-<strong>880</strong> on Models TH, THD, or vice versa.<br />

BATTERY IGNITION<br />

DISTRIBUTOR<br />

A distributor is furnished in place of magneto, on engines<br />

that are equipped with a generator or flywheel<br />

alternator.<br />

When a direct mounted generator is provided, the dis~<br />

t ributor is mounted to the end of the generator frame<br />

as illustrated in Fig. ]6. On engines wiith belt driven<br />

generator or flywheel alternator, the distributor is<br />

)IRECTION AS<br />

CLAMP SCREW )W<br />

Fig, 16, DISTRIBUTOR TIMING<br />

14