9-2015

Fachzeitschrift für Hochfrequenz- und Mikrowellentechnik

Fachzeitschrift für Hochfrequenz- und Mikrowellentechnik

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

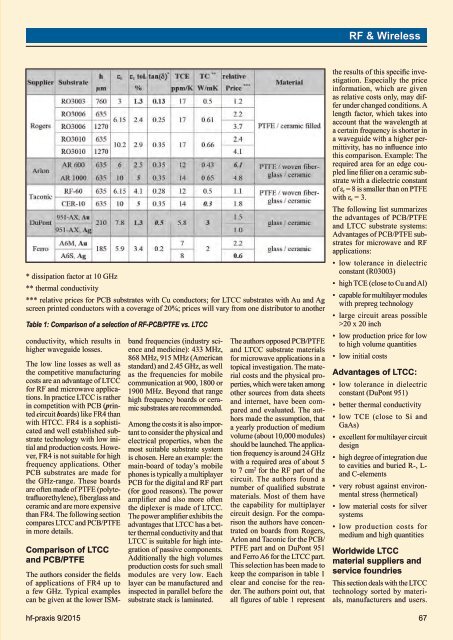

RF & Wireless* dissipation factor at 10 GHz** thermal conductivity*** relative prices for PCB substrates with Cu conductors; for LTCC substrates with Au and Agscreen printed conductors with a coverage of 20%; prices will vary from one distributor to anotherTable 1: Comparison of a selection of RF-PCB/PTFE vs. LTCCconductivity, which results inhigher waveguide losses.The low line losses as well asthe competitive manufacturingcosts are an advantage of LTCCfor RF and microwave applications.In practice LTCC is ratherin competition with PCB (printedcircuit boards) like FR4 thanwith HTCC. FR4 is a sophisticatedand well established substratetechnology with low initialand production costs. However,FR4 is not suitable for highfrequency applications. OtherPCB substrates are made forthe GHz-range. These boardsare often made of PTFE (polytetrafluorethylene),fiberglass andceramic and are more expensivethan FR4. The following sectioncompares LTCC and PCB/PTFEin more details.Comparison of LTCCand PCB/PTFEThe authors consider the fieldsof applications of FR4 up toa few GHz. Typical examplescan be given at the lower ISMbandfrequencies (industry scienceand medicine): 433 MHz,868 MHz, 915 MHz (Americanstandard) and 2.45 GHz, as wellas the frequencies for mobilecommunication at 900, 1800 or1900 MHz. Beyond that rangehigh frequency boards or ceramicsubstrates are recommended.Among the costs it is also importantto consider the physical andelectrical properties, when themost suitable substrate systemis chosen. Here an example: themain-board of today’s mobilephones is typically a multiplayerPCB for the digital and RF part(for good reasons). The poweramplifier and also more oftenthe diplexer is made of LTCC.The power amplifier exhibits theadvantages that LTCC has a betterthermal conductivity and thatLTCC is suitable for high integrationof passive components.Additionally the high volumesproduction costs for such smallmodules are very low. Eachlayer can be manufactured andinspected in parallel before thesubstrate stack is laminated.The authors opposed PCB/PTFEand LTCC substrate materialsfor microwave applications in atopical investigation. The materialcosts and the physical properties,which were taken amongother sources from data sheetsand internet, have been comparedand evaluated. The authorsmade the assumption, thata yearly production of mediumvolume (about 10,000 modules)should be launched. The applicationfrequency is around 24 GHzwith a required area of about 5to 7 cm 2 for the RF part of thecircuit. The authors found anumber of qualified substratematerials. Most of them havethe capability for multiplayercircuit design. For the comparisonthe authors have concentratedon boards from Rogers,Arlon and Taconic for the PCB/PTFE part and on DuPont 951and Ferro A6 for the LTCC part.This selection has been made tokeep the comparison in table 1clear and concise for the reader.The authors point out, thatall figures of table 1 representthe results of this specific investigation.Especially the priceinformation, which are givenas relative costs only, may differunder changed conditions. Alength factor, which takes intoaccount that the wavelength ata certain frequency is shorter ina waveguide with a higher permittivity,has no influence intothis comparison. Example: Therequired area for an edge coupledline filier on a ceramic substratewith a dielectric constantof ε r = 8 is smaller than on PTFEwith ε r = 3.The following list summarizesthe advantages of PCB/PTFEand LTCC substrate systems:Advantages of PCB/PTFE substratesfor microwave and RFapplications:• low tolerance in dielectricconstant (R03003)• high TCE (close to Cu and Al)• capable for multilayer moduleswith prepreg technology• large circuit areas possible>20 x 20 inch• low production price for lowto high volume quantities• low initial costsAdvantages of LTCC:• low tolerance in dielectricconstant (DuPont 951)• better thermal conductivity• low TCE (close to Si andGaAs)• excellent for multilayer circuitdesign• high degree of integration dueto cavities and buried R-, L-and C-elements• very robust against environmentalstress (hermetical)• low material costs for silversystems• low production costs formedium and high quantitiesWorldwide LTCCmaterial suppliers andservice foundriesThis section deals with the LTCCtechnology sorted by materials,manufacturers and users.hf-praxis 9/<strong>2015</strong> 67