Bulletin 1/2011 - Siempelkamp

Bulletin 1/2011 - Siempelkamp

Bulletin 1/2011 - Siempelkamp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SieMpelkaMp | nUCLEAR tECHnOLOGy<br />

What is a lifting device?<br />

A lifting device is a mechanical support system which can be<br />

used for different applications, for stabilization, for mounting<br />

or connecting parts. It is used in constructions or as a load<br />

suspension device for attaching loads. the lifting devices have<br />

manual or automatic coupling systems for the loads that<br />

require lifting, some of them even come with an emergency<br />

operation system.<br />

SNT: the specialist for handling nuclear loads<br />

<strong>Siempelkamp</strong> nukleartechnik designs, manufactures, and<br />

delivers lifting devices for all common reactor types of the<br />

latest EPR generation as well as for the predecessor types.<br />

For over ten years the company has placed these products<br />

successfully in the nuclear technology field. In the beginning<br />

of <strong>2011</strong> a lifting device for the reactor pressure vessel closure<br />

head and an internal lifting device (for the handling of<br />

pressure vessel internals) were delivered for the new building<br />

Flamanville 3 in France. With the current orders in China and<br />

Germany, Snt together with <strong>Siempelkamp</strong> Maschinen- und<br />

Anlagenbau have started the “Generation Joint Product”.<br />

the extensive range of products consists of lifting devices for<br />

pressure vessel internals, the pressure vessel closure head and<br />

test load systems.<br />

Services:<br />

• Engineering in-house and third-party design<br />

• Supervision and management of approval processes,<br />

i.e., working with surveyors and authorities<br />

• Quality-assured production including material procurement<br />

according to the nuclear safety regulations<br />

• Production of all individual components including all<br />

inspection steps by the surveyor and customer<br />

• Assembly of components<br />

• Static and dynamic load tests<br />

• Acceptance test, i.e., the joint documentation<br />

with the customer and surveyors<br />

• High quality – highest safety<br />

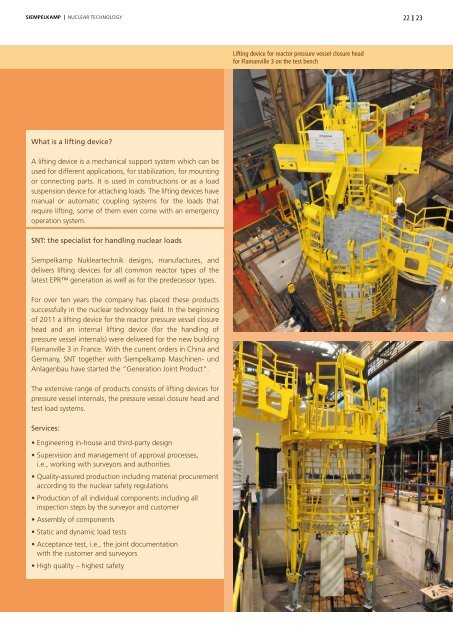

Lifting device for reactor pressure vessel closure head<br />

for Flamanville 3 on the test bench<br />

22<br />

23