Bulletin 1/2011 - Siempelkamp

Bulletin 1/2011 - Siempelkamp

Bulletin 1/2011 - Siempelkamp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SieMpelkaMp | nUCLEAR tECHnOLOGy 44 45<br />

Crane system with efficiency effect<br />

With the help of the swivel arms, the employees<br />

can use the required welding technology<br />

in different manual work areas<br />

which ensures MEyER WERFt the necessary<br />

flexibility and availability. In the past the<br />

employees had to transport the welding<br />

machines with hose set and media a<br />

distance of up to 40 m from the side areas<br />

to the site of operation. now overhead<br />

cranes provide efficiency: At every welding<br />

workstation, welding sets tailored to the<br />

station’s requirements are readily available<br />

and equipped with the welding wire feed,<br />

the supply with welding gases as well as<br />

compressed air and an exhaust system.<br />

travel and set-up times are optimized by<br />

the cranes.<br />

Vacuum lifting device with individually<br />

controllable suction cups<br />

the work areas of the eight overhead<br />

cranes overlap so that several cranes can<br />

be available for one subarea if needed.<br />

the power supply of the system was<br />

implemented with a system of concurrent<br />

and non-concurrent energy chains.<br />

We continue to accompany the impressive<br />

development of MEyER WERFt. Currently,<br />

SKt is developing innovative concepts for<br />

new crane systems together with the shipbuilder<br />

and is looking forward to the<br />

maiden voyages of the projects in which<br />

SKt technology has a share.<br />

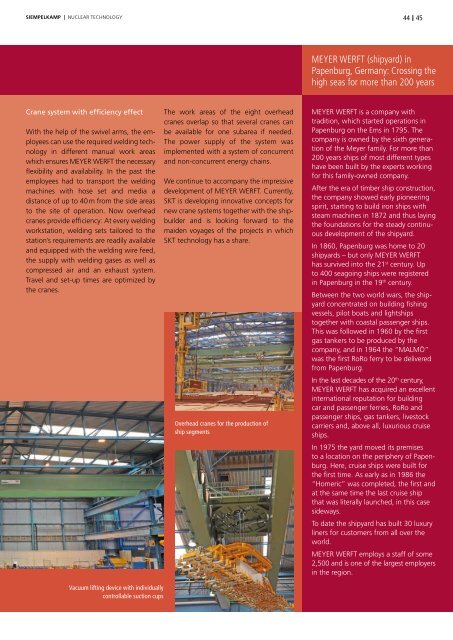

Overhead cranes for the production of<br />

ship segments<br />

MEYER WERFT (shipyard) in<br />

Papenburg, Germany: Crossing the<br />

high seas for more than 200 years<br />

MEyER WERFt is a company with<br />

tradition, which started operations in<br />

Papenburg on the Ems in 1795. the<br />

company is owned by the sixth generation<br />

of the Meyer family. For more than<br />

200 years ships of most different types<br />

have been built by the experts working<br />

for this family-owned company.<br />

After the era of timber ship construction,<br />

the company showed early pioneering<br />

spirit, starting to build iron ships with<br />

steam machines in 1872 and thus laying<br />

the foundations for the steady continuous<br />

development of the shipyard.<br />

In 1860, Papenburg was home to 20<br />

shipyards – but only MEyER WERFt<br />

has survived into the 21st century. Up<br />

to 400 seagoing ships were registered<br />

in Papenburg in the 19th century.<br />

Between the two world wars, the shipyard<br />

concentrated on building fishing<br />

vessels, pilot boats and lightships<br />

together with coastal passenger ships.<br />

this was followed in 1960 by the first<br />

gas tankers to be produced by the<br />

company, and in 1964 the “MALMÖ”<br />

was the first RoRo ferry to be delivered<br />

from Papenburg.<br />

In the last decades of the 20th century,<br />

MEyER WERFt has acquired an excellent<br />

international reputation for building<br />

car and passenger ferries, RoRo and<br />

passenger ships, gas tankers, livestock<br />

carriers and, above all, luxurious cruise<br />

ships.<br />

In 1975 the yard moved its premises<br />

to a location on the periphery of Papenburg.<br />

Here, cruise ships were built for<br />

the first time. As early as in 1986 the<br />

“Homeric” was completed, the first and<br />

at the same time the last cruise ship<br />

that was literally launched, in this case<br />

sideways.<br />

to date the shipyard has built 30 luxury<br />

liners for customers from all over the<br />

world.<br />

MEyER WERFt employs a staff of some<br />

2,500 and is one of the largest employers<br />

in the region.