Bulletin 1/2011 - Siempelkamp

Bulletin 1/2011 - Siempelkamp

Bulletin 1/2011 - Siempelkamp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SieMpelkaMp | MACHInERy AnD PLAntS<br />

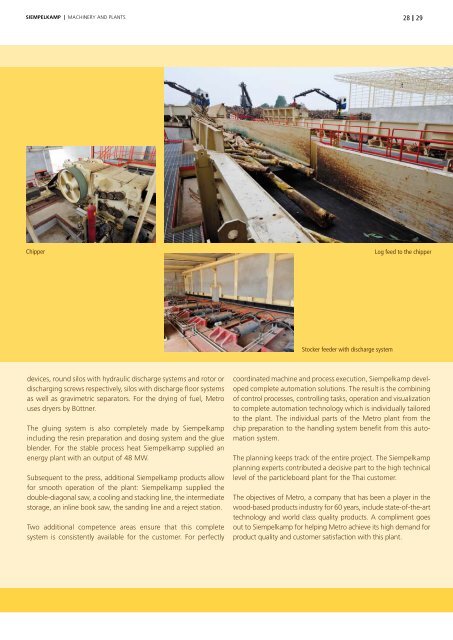

Chipper<br />

devices, round silos with hydraulic discharge systems and rotor or<br />

discharging screws respectively, silos with discharge floor systems<br />

as well as gravimetric separators. For the drying of fuel, Metro<br />

uses dryers by Büttner.<br />

the gluing system is also completely made by <strong>Siempelkamp</strong><br />

including the resin preparation and dosing system and the glue<br />

blender. For the stable process heat <strong>Siempelkamp</strong> supplied an<br />

energy plant with an output of 48 MW.<br />

Subsequent to the press, additional <strong>Siempelkamp</strong> products allow<br />

for smooth operation of the plant: <strong>Siempelkamp</strong> supplied the<br />

double-diagonal saw, a cooling and stacking line, the intermediate<br />

storage, an inline book saw, the sanding line and a reject station.<br />

two additional competence areas ensure that this complete<br />

system is consistently available for the customer. For perfectly<br />

Stocker feeder with discharge system<br />

28<br />

29<br />

Log feed to the chipper<br />

coordinated machine and process execution, <strong>Siempelkamp</strong> developed<br />

complete automation solutions. the result is the combining<br />

of control processes, controlling tasks, operation and visualization<br />

to complete automation technology which is individually tailored<br />

to the plant. the individual parts of the Metro plant from the<br />

chip preparation to the handling system benefit from this automation<br />

system.<br />

the planning keeps track of the entire project. the <strong>Siempelkamp</strong><br />

planning experts contributed a decisive part to the high technical<br />

level of the particleboard plant for the thai customer.<br />

the objectives of Metro, a company that has been a player in the<br />

wood-based products industry for 60 years, include state-of-the-art<br />

technology and world class quality products. A compliment goes<br />

out to <strong>Siempelkamp</strong> for helping Metro achieve its high demand for<br />

product quality and customer satisfaction with this plant.