Bulletin 1/2011 - Siempelkamp

Bulletin 1/2011 - Siempelkamp

Bulletin 1/2011 - Siempelkamp

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SieMpelkaMp | MACHInERy AnD PLAntS<br />

harmony<br />

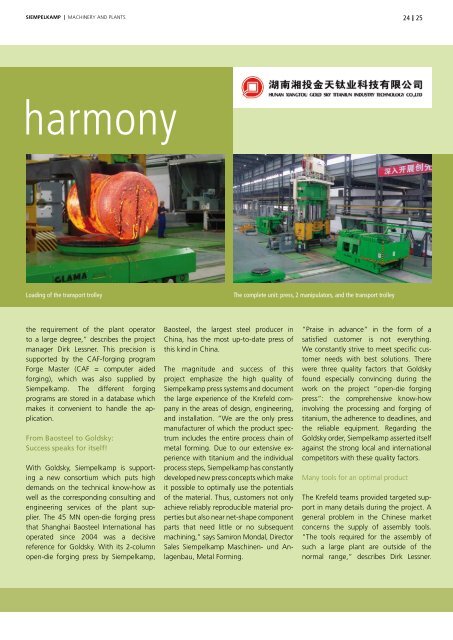

Loading of the transport trolley The complete unit: press, 2 manipulators, and the transport trolley<br />

the requirement of the plant operator<br />

to a large degree,” describes the project<br />

manager Dirk Lessner. this precision is<br />

supported by the CAF-forging program<br />

Forge Master (CAF = computer aided<br />

forging), which was also supplied by<br />

<strong>Siempelkamp</strong>. the different forging<br />

programs are stored in a database which<br />

makes it convenient to handle the ap-<br />

p lication.<br />

From Baosteel to Goldsky:<br />

Success speaks for itself!<br />

With Goldsky, <strong>Siempelkamp</strong> is supporting<br />

a new consortium which puts high<br />

demands on the technical know-how as<br />

well as the corresponding consulting and<br />

engineering services of the plant supplier.<br />

the 45 Mn open-die forging press<br />

that Shanghai Baosteel International has<br />

operated since 2004 was a decisive<br />

reference for Goldsky. With its 2-column<br />

open-die forging press by <strong>Siempelkamp</strong>,<br />

Baosteel, the largest steel producer in<br />

China, has the most up-to-date press of<br />

this kind in China.<br />

the magnitude and success of this<br />

project emphasize the high quality of<br />

<strong>Siempelkamp</strong> press systems and document<br />

the large experience of the Krefeld company<br />

in the areas of design, engineering,<br />

and installation. “We are the only press<br />

manufacturer of which the product spectrum<br />

includes the entire process chain of<br />

metal forming. Due to our extensive experience<br />

with titanium and the individual<br />

process steps, <strong>Siempelkamp</strong> has constantly<br />

developed new press concepts which make<br />

it possible to optimally use the potentials<br />

of the material. thus, customers not only<br />

achieve reliably reproducible material properties<br />

but also near net-shape component<br />

parts that need little or no subsequent<br />

machining,” says Samiron Mondal, Director<br />

Sales <strong>Siempelkamp</strong> Maschinen- und Anlagenbau,<br />

Metal Forming.<br />

24<br />

25<br />

“Praise in advance” in the form of a<br />

satisfied customer is not everything.<br />

We constantly strive to meet specific customer<br />

needs with best solutions. there<br />

were three quality factors that Goldsky<br />

found especially convincing during the<br />

work on the project “open-die forging<br />

press”: the comprehensive know-how<br />

involving the processing and forging of<br />

titanium, the adherence to deadlines, and<br />

the reliable equipment. Regarding the<br />

Goldsky order, <strong>Siempelkamp</strong> asserted itself<br />

against the strong local and international<br />

competitors with these quality factors.<br />

Many tools for an optimal product<br />

the Krefeld teams provided targeted support<br />

in many details during the project. A<br />

general problem in the Chinese market<br />

concerns the supply of assembly tools.<br />

“the tools required for the assembly of<br />

such a large plant are outside of the<br />

normal range,” describes Dirk Lessner.