717 Engines

717 Engines

717 Engines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Remove cylinder head no. 2.<br />

If shells, sand, salt water or any other particles<br />

are present in cylinder cooling jacket, clean with<br />

a vacuum cleaner.<br />

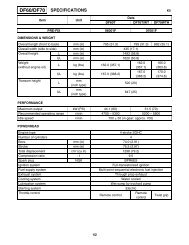

947 DI <strong>Engines</strong><br />

Disconnect hose of RAVE valves. Remove air/fuel<br />

rail. Refer to ENGINE MANAGEMENT.<br />

Use Snap-On Torx socket E12 and unscrew cylinder<br />

head screws no. 14 following the sequence<br />

shown in the next illustration.<br />

2<br />

F12D08B<br />

6<br />

1<br />

9<br />

12<br />

7<br />

5<br />

11<br />

3<br />

10 8<br />

Remove cylinder head no. 2 and gasket no. 34.<br />

Cylinder<br />

NOTE: When removing cylinder, make sure connecting<br />

rods do not hit crankcase edge.<br />

787 RFI <strong>Engines</strong><br />

Remove air intake silencer and support, refer to<br />

AIR INTAKE.<br />

<strong>717</strong> and 787 RFI <strong>Engines</strong><br />

Remove tuned pipe and exhaust manifold, refer to<br />

EXHAUST SYSTEM.<br />

Remove screws no. 13.<br />

Remove cylinders no. 9, while making sure connecting<br />

rods do not hit crankcase edge.<br />

WARNING<br />

If screws need to be heated for removal when<br />

engine is in watercraft, fuel system pressurization<br />

must be done first. Do not use open<br />

flame; use a heat gun.<br />

NOTE: Even if only 1 cylinder needs repair, both<br />

cylinders should be lifted to allow 1-piece cylinder<br />

base gasket replacement.<br />

4<br />

Section 04 ENGINE (2-STROKE)<br />

Subsection 04 (TOP END)<br />

947 DI <strong>Engines</strong><br />

Remove cylinders screws then cylinders no. 9.<br />

Piston<br />

NOTE: All engines feature cageless piston pin<br />

bearings.<br />

<strong>717</strong> and 787 RFI <strong>Engines</strong><br />

Bring piston to Top Dead Center and install rubber<br />

pad (P/N 295 000 101) over crankcase opening.<br />

Secure with screws. Lower piston until it sits on<br />

pad.<br />

F01B0JA<br />

1. Rubber pad (P/N 295 000 101)<br />

1<br />

If the other cylinder has been removed, completely<br />

cover its opening with a clean rag.<br />

F01D43A<br />

1. Openings covered with rag and rubber pad<br />

947 DI <strong>Engines</strong><br />

Install rubber pad (P/N 290 877 032) on crankcase.<br />

Secure with screws. Lower piston to be removed<br />

until it sits on pad.<br />

smr2004-Complete Line Up 109<br />

11<br />

1