717 Engines

717 Engines

717 Engines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

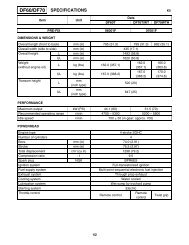

Section 04 ENGINE (2-STROKE)<br />

Subsection 05 (BOTTOM END)<br />

F00D2DA<br />

SECOND PASS<br />

Finish the cleaning with acetone.<br />

CAUTION: Ensure to clean compressor lubrication<br />

nipple.<br />

CAUTION: Be careful not to spray cleaner on<br />

the painted surface of the engine.<br />

CAUTION: Never use a sharp object to scrape<br />

away old sealant as score marks incurred are<br />

detrimental to crankcase sealing.<br />

INSPECTION<br />

Assembled Engine<br />

The following checks can be performed with engine<br />

in watercraft without overhauling engine.<br />

Crankshaft Alignment at Center<br />

Main Journal<br />

Since it is an assembled crankshaft it can become<br />

misaligned or deflected. Crankshaft can be twisted<br />

on center main journal, changing timing of one<br />

cylinder in relation with the other.<br />

F01D1NA<br />

1. Main journal alignment here<br />

1<br />

To accurately check if crankshaft is twisted on center<br />

main journal, proceed as follows:<br />

– Remove magneto housing cover.<br />

– Remove flywheel nut (and magneto rotor for<br />

the 787 RFI and 947 DI engines). Refer to<br />

MAGNETO SYSTEM for procedures.<br />

– Install Bombardier degree wheel (P/N 529 035<br />

607)) on crankshaft end. Hand-tighten nut only.<br />

– Remove both spark plugs.<br />

– Install a TDC gauge in spark plug hole on MAG<br />

side.<br />

– Bring MAG piston at Top Dead Center.<br />

– As a needle pointer, secure a wire with a cover<br />

screw and a washer.<br />

– Rotate degree wheel (NOT crankshaft) so that<br />

needle pointer reads 360°.<br />

140 smr2004-Complete Line Up