717 Engines

717 Engines

717 Engines

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NOTE: Crankshaft deflection cannot be correctly<br />

measured between centers of a lathe.<br />

Connecting Rod Big End Axial Play<br />

CONNECTING ROD BIG END AXIAL PLAY<br />

MODEL<br />

<strong>717</strong><br />

engines<br />

787 RFI<br />

engines<br />

947 DI<br />

engines<br />

NEW PARTS<br />

(min.) (max.)<br />

0.311 mm<br />

(.012 in)<br />

0.230 mm<br />

(.008 in)<br />

0.390 mm<br />

(.015 in)<br />

0.677 mm<br />

(.026 in)<br />

0.617 mm<br />

(.024 in)<br />

0.737 mm<br />

(.029 in)<br />

WEAR<br />

LIMIT<br />

1.2 mm<br />

(.047 in)<br />

1.2 mm<br />

(.047 in)<br />

1.2 mm<br />

(.047 in)<br />

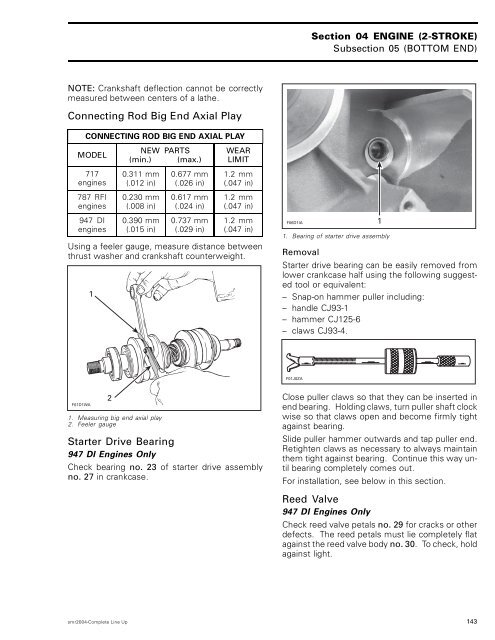

Using a feeler gauge, measure distance between<br />

thrust washer and crankshaft counterweight.<br />

F01D1WA<br />

1<br />

2<br />

1. Measuring big end axial play<br />

2. Feeler gauge<br />

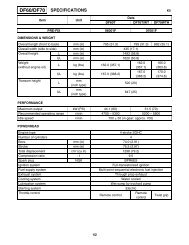

Starter Drive Bearing<br />

947 DI <strong>Engines</strong> Only<br />

Check bearing no. 23 of starter drive assembly<br />

no. 27 in crankcase.<br />

F06D1IA<br />

Section 04 ENGINE (2-STROKE)<br />

Subsection 05 (BOTTOM END)<br />

1. Bearing of starter drive assembly<br />

1<br />

Removal<br />

Starter drive bearing can be easily removed from<br />

lower crankcase half using the following suggested<br />

tool or equivalent:<br />

– Snap-onhammerpullerincluding:<br />

– handle CJ93-1<br />

– hammer CJ125-6<br />

– claws CJ93-4.<br />

F01J0ZA<br />

Closepullerclawssothattheycanbeinsertedin<br />

end bearing. Holding claws, turn puller shaft clock<br />

wise so that claws open and become firmly tight<br />

against bearing.<br />

Slide puller hammer outwards and tap puller end.<br />

Retighten claws as necessary to always maintain<br />

them tight against bearing. Continue this way until<br />

bearing completely comes out.<br />

For installation, see below in this section.<br />

Reed Valve<br />

947 DI <strong>Engines</strong> Only<br />

Check reed valve petals no. 29 for cracks or other<br />

defects. The reed petals must lie completely flat<br />

against the reed valve body no. 30. To check, hold<br />

against light.<br />

smr2004-Complete Line Up 143