717 Engines

717 Engines

717 Engines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A<br />

F01D8AA<br />

2<br />

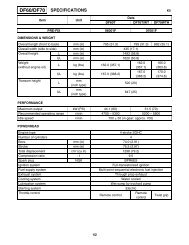

1. Measuring perpendicularly (90°) topistonpinaxis<br />

2. Auxiliary transfer port<br />

A. 16 mm (5/8 in)<br />

1<br />

Cylinder Out of Round<br />

Using a cylinder bore gauge, measure cylinder<br />

diameter at 16 mm (5/8 in) from top of cylinder.<br />

Measure diameter in piston pin axis direction<br />

then perpendicularly (90°) to it. If the difference<br />

between readings exceed specification, cylinder<br />

should be rebored and honed or replaced.<br />

F01D8BA<br />

Section 04 ENGINE (2-STROKE)<br />

Subsection 04 (TOP END)<br />

A<br />

1. Measuringinpistonpinaxis<br />

2. Measuring perpendicularly (90°) to piston pin axis<br />

A. 16 mm (5/8 in)<br />

1<br />

USED PISTON MEASUREMENT<br />

Note the measurement on the piston dome.<br />

F00D0EA 2 1<br />

1. Piston dome<br />

2. Piston measurement<br />

Using a micrometer, measure piston skirt perpendicularly<br />

(90°) to piston pin according to the following<br />

table.<br />

ENGINE TYPE MAXIMUM “A” mm (in)<br />

<strong>717</strong> 29 (1.142)<br />

smr2004-Complete Line Up 113<br />

15<br />

A<br />

2